Autonomous heating of a private house involves not only the installation of the boiler, but also the installation of the "warm floor" system. One of the functional structural elements is the pipe for the underfloor heating, along which the heat carrier is transported. The efficiency and durability of the system depends on the material of the pipes, so the choice should be approached responsibly.

What criteria to choose

The principle of operation of a water heating system is simple and understandable: the circuits are laid on the floor in the room and warm water is allowed through them. However, the correct operation of the entire system is affected not only by the laying of the pipes, but also by their technical properties, material of manufacture and thermal conductivity.

When choosing which pipe to choose for a warm water floor, the following criteria are considered:

- the optimal cross-section of the pipe is 16 mm when laying it in the screed;

- use material with appropriate labeling;

- resistance of pipes to coolant pressure drops;

- the material should easily tolerate high temperatures;

- resistance of pipes to mechanical stress;

- maintainability and simple operation of the pipeline.

Water contour pipes ensure trouble-free operation of the heating system and its durability.

Pipe requirements for underfloor heating

To understand which pipes for a heat carrier it is better to purchase for warm water floors, you need to understand the requirements that they must meet. In most cases, the circuit is laid along the floor and poured with a concrete screed. Therefore, you can not think about a periodic audit of the state of the channels through which water circulates.

To understand which pipes for a heat carrier it is better to purchase for warm water floors, you need to understand the requirements that they must meet. In most cases, the circuit is laid along the floor and poured with a concrete screed. Therefore, you can not think about a periodic audit of the state of the channels through which water circulates.

The screed reliably protects the system from mechanical damage, but significantly complicates the identification and elimination of leaks. Therefore, it is so important to choose the right supplies:

- Products must resist corrosion, do not decompose over time under the influence of high temperatures and coolant composition.

- When laying one circuit, the pipe must be monolithic, since each connection point is a potential threat of leakage and clogging.

- When laying the channels with a “snake” or “snail”, creases should not form on turning areas, therefore, flexibility should be high.

- A pipe with a cross section of 16 mm allows you to lay a single circuit, the length of which will be 50-80 m. Products with a diameter of 25 mm allow you to mount circuits up to 100 m long.

- The durability of the pipe material affects the durability of the system - they have to withstand the external load from the screed and the internal one from the differences in hydraulic pressure.

The smooth inner surface of the channels will guarantee the silent operation of the system.

Materials and their characteristics

For the installation of a warm floor, several types of pipes are used. They differ in the material of manufacture and operational properties.

Polyethylene

Cross-linked polyethylene pipes are the most common type of circuit. They are distinguished from ordinary polyethylene by an improved structure that is resistant to thermal influences. Crosslinked polyethylene has the following qualities:

- characterized by chemical and electrical inertness;

- resistant to aggressive environments and the formation of corrosion;

- the smooth inner surface of the circuit reduces the hydraulic resistance, reduces the likelihood of clogging inside the channel;

- the material is very durable, not afraid of high temperatures;

- high elasticity makes it possible to set the contour to the required radius without the use of special tools.

Cross-linked polyethylene has a "structural memory" - this is its main difference from other materials. Due to this property, during mechanical creasing after heating, the circuit takes on its original shape.

Fittings made of polymers, brass and bronze are used to connect the pipes. The connection is reliable and durable. The light weight of the products and their winding into compact reels simplifies the process of transportation and installation.

Stainless steel

Corrugated stainless steel pipe has high performance characteristics, putting it one step higher than products from other materials. Plasticity and strength are the main criteria for choosing a contour for a warm floor.

The service life of a corrugated stainless pipe is at least 20 years, which allows you to mount it in a screed and not to worry about prevention and repair for many years.

The advantages of steel corrugation include:

- flexibility and elasticity, which provide easy installation;

- reliable connection with fittings;

- resistance to mechanical stress;

- resistance to temperature changes;

- resistance to high temperatures;

- resistance to corrosion;

- resistance to pressure drops;

- reasonable price.

One of the advantages of steel is its unpretentiousness. It does not need to be cleaned or replaced throughout its life. You can use the online calculator to calculate the amount of material.

Metal plastic

The best choice in terms of price and quality is metal. This is a multilayer material in which an aluminum gasket connects two polyethylene layers of different thicknesses. Polyethylene in the composition of the pipe provides high heat transfer and high-quality heating of the base.

The advantages of metal plastic include:

- flexibility and flexibility, allowing to form the necessary radius;

- resistance to corrosion;

- resistance to high temperatures;

- chemical resistance;

- smooth inner surface.

The weak point of the metal-plastic pipeline is the connecting fittings. They can accumulate scale, so for ease of maintenance they are placed above the screed near the walls.

Copper

The copper pipeline has the entire spectrum of positive properties that will ensure long and uninterrupted operation of the warm floor. Copper is ductile, therefore, its products are characterized by mechanical resistance. Copper is one of the durable materials whose chemical composition is able to withstand corrosion.

In the manufacture of copper pipes, their inner surface is covered with a polymer film, which extends the service life of the product by tens of years. Despite all their advantages, copper circuits are not often used. This is due to complicated installation - to give the pipe the required radius, you need to use a special tool. Therefore, the cost of such a warm floor increases significantly.

Polypropylene

The only plus of this material is its low cost. There are plenty of minuses, so that this option is not even considered. Polypropylene pipes have a small length, so when connecting them, it is necessary to use welding. Many connection points pose a real threat of leakage. Using such pipes, it is impossible to create contours with a small radius.

In favor of polypropylene, it is worth noting the high thermal conductivity, corrosion resistance of the material and chemical inertness.

How to calculate pipe diameter and footage

The calculation of the pipes is performed using the formula S / h x 1.1 + d x 2 = Lwhere:

The calculation of the pipes is performed using the formula S / h x 1.1 + d x 2 = Lwhere:

- L - the required length of the circuit in meters;

- S - area of the room in m2;

- h - pipe laying step;

- d - distance between the room and the collector.

During installation, there is a chance of marriage due to improper trimming of the material, so it is necessary to provide a margin of 10%. This value in the formula is in the coefficient 1.1.

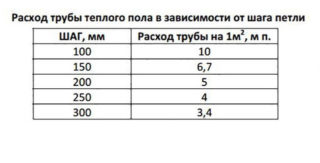

The step of laying the circuit is determined depending on the necessary heat transfer and the cross-section of the pipes.

If massive furnishings will be placed in the room, it is not recommended to lay the system under them. Then the formula is slightly modified: the area under the furniture, which will not be involved, is taken from the total area (S - S1).

Rating of popular manufacturers

There are proven brands of pipes for water floors, which are recommended by professionals:

- Valtec. A Chinese manufacturer of cross-linked polyethylene pipes with an outer protective layer of Evoh (ethylene vinyl). The material is intended for domestic use in heating systems.

- Knauf. The German manufacturer produces not only drywall, but also Therm Pert Evoh pipes with rust protection. Contours can be used for pouring screeds and laying on mats.

- Rehau. It produces products equipped with a sliding sleeve for a tight connection.

When choosing all the elements of a water heating system, it is necessary to focus on the quality of products. This is the only way to ensure the correct and long operation of the warm floor.