A cast iron stove stove, also called a cooktop, allows you to cook and improve the heating of the room. Due to the properties of cast iron at the panel, inertial heat transfer: during the slow cooling of the surface, uniform heating of the house or cottage is carried out. To tile served for a long time, without losing useful qualities, you need to responsibly approach its selection and installation.

Cast Iron Plate Characteristics

The hob is installed on top of the horizontal plane of the furnace. It is made by casting from gray cast iron grade SCh 15-20. This strong and refractory metal is an iron-carbon alloy, which also includes silicon, phosphorus, manganese and sulfur. These impurities significantly increase the physical and chemical properties of the metal.

The cast iron hob for the oven is characterized by such qualities:

- Resistance to temperature surges. The product does not deform when following the rules of use.

- Corrosion-resistant characteristics. Immediately after casting, the panels are covered with a layer of rust, so that they become immune to corrosion.

- Great weight. Cast iron plates are heavy, which gives them stability.

The requirements for the quality of the product are such as evenness of the surface, the absence of scratches, chips and other damages.

Varieties of cast iron hob

Regardless of the configuration, all the tiles perfectly perform the heat transfer function, you can cook food on them. Cooking floors are of two types - prefabricated and solid. The difference between the former in the thermal gaps between the parts, due to which the expansion of the heated metal is compensated. But each type has additional features.

Prefabricated Slabs

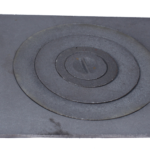

Structurally, they look like metal panels with several rings of various diameters, which are installed in each other. The result is a single plane. Prefabricated stove stoves can have from one to six burners, and their size can be varied for a certain dish by removing and putting on rings.

Cast iron prefabricated plates for the stove are characterized by a long operating period and resistance to temperature extremes. Due to the inter-ring gaps, cast iron, which expands when heated, is not deformed or damaged.

To make products more durable, they are equipped with stiffening ribs from the inside. A significant advantage of this supplement is an increase in panel temperature and an increase in efficiency.

Solid plates

These are sheets of cast iron with one or two round burners of constant cross-section. There are also deaf models, which are a solid non-burner sheet. Solid models have almost no expansion gaps, which is why it is not as practical and durable as a prefabricated analogue. Due to the lack of free space, deformation of the heating panel may occur. But there are advantages for one-type stoves for the furnace - ease of installation and low price in comparison with prefabricated ones.

- Solid plate

- Prefab Cooker

Hob selection criteria

First, evaluate the size of the panel. This is done at the stage of erection of the stove according to the drawings or after, if the tile is supposed to be embedded in the finished product. Cast iron surfaces are square or rectangular. Most often they are produced in the following sizes:

- 340x410 mm;

- 340x510 mm;

- 340x585 mm;

- 410x660 mm;

- 410x710 mm.

From 8 to 17 mm are produced according to the thickness of the surface - it is important to take into account the criterion if the cooking utensils are dimensional and heavy. The weight of the panel is from 10 to 55 kg.

The number of cast iron burners for different furnaces depends on the dimensions of the sheet and the desire of the owner: there are single-burner options, there are products with six heating points. For a non-standard furnace in a specialized store, you can make an order for the production of cast-iron surfaces according to individual sizes. But its cost is much more than a standard plate.

It is worth considering the quality and composition of the material used to make the panel. If chips, scratches and other flaws are found on the surface, it is better to refuse the acquisition.

Cooking surfaces are produced by domestic and foreign manufacturers. Of the latter, products from the Finnish brand Pisla are in demand. For example, the two-burner stove stove cast iron NTT 3A black 985 x 650 mm has proven itself well. In addition, the company offers cast iron products for fireplaces. Domestic production does not lag behind its foreign competitors. The most popular Russian manufacturers are NMK, Litkom, Russian Casting, Furnace Casting Russia, SibStalShar.

Subtleties of installation

During installation, the thermal expansion of various materials must be taken into account. For example, brick and cast iron are affected in very different ways by high temperatures. If during installation the hob is tightly walled up in masonry, soon such a furnace will simply fall apart as a result of the expansion of the metal.

Installing tiles on a brick stove:

- A horizontal 5 mm gap is left between the heating structure and the panel. Thanks to him, the thermal expansion between the objects will be compensated, the period of operation will increase.

- The hob is installed in a strictly horizontal position on an even base - the tile should not play. To determine if there are any deviations in the horizon, apply the construction level. The largest of the cast iron circles for the furnace is located above the furnace compartment.

- The panel is mounted on a clay-asbestos composition. These materials are resistant to high temperatures. The solution can be made by yourself, grinding and mixing the components with water, or dilute the ready-made one. By consistency, it should look like liquid sour cream. When installing, make sure that the horizontal gaps remain empty, otherwise the stove will quickly collapse.

- An asbestos cord or web is laid under the base of the panel.

- The upper row of bricks, on which a cast-iron sheet is placed, is “ringed” with a corner of metal - this will give strength to the structure.

The furnace should be heated for the first time after installing the surface in a special way: after mounting the panel, gradually warm it up to 640 degrees for 8 hours, adding 70–80 degrees per hour. When the required temperature is reached, the furnace cools down until the fuel burns to the end.

Due to gradual heating, the internal stress of cast iron is removed, the stove plate becomes more durable. The procedure positively affects the further operation of the stove and tile, preventing bending and cracking.

Mounting on a metal stove follows the same principles. But it must be taken into account that cast iron is a heavy material, therefore a brick structure is able to deform under its weight. An additional reinforcement of the furnace with a cast-iron corner is required. You can apply the "backup" and from another resistant material.

Care and maintenance rules

Cast iron surfaces are designed for use on domestic stoves that require solid fuels - firewood, pellets or coal. The panel is easy to operate. You just need to heat the stove and wait until the burners heat up.

When working with tiles, you must follow the rules:

- Do not spill liquid on a hot panel.

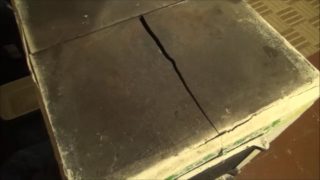

- Avoid shock and other mechanical influences during transportation or during use.

- Do not overload the stove.

The hob does not need to be treated with any chemical solutions. To care for it, it is necessary to systematically wipe the cooled panel with a damp cloth, remove burnt food remains with a brush with a hard pile. Do not worry, if rust appears on cast iron as a result of a long period of inactivity, it will disappear when the surface heats up.

Cast iron is unpretentious material, but at the same time it has its own weaknesses. The main disadvantage is fragility. Inaccurate handling of the product or due to impacts on it, cracks and chips form on the surface. Such a panel can only be thrown away, since it will not work to fix defects by welding.