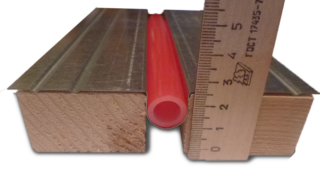

The warm water floor is mounted in a dry way using heat-exchange elements made of aluminum or steel. The heat distribution plate for the warm floor is equipped with a groove along the entire length for laying the water pipe and stiffeners on the side parts. The element heats up from the water circuit and evenly transfers heat to the floor.

Features of heat distribution plate

The energy carrier in the pipes of the warm floor does not need to be heated to high temperatures, compared with radiators, thanks to the use of heat-reflecting plates. Aluminum or steel elements are simple in structure and have no restrictions on use.

Products from different manufacturers differ in configuration, but the overall structure remains the same:

- omega-shaped gutter runs from beginning to end and serves to install a water pipe;

- protruding strips on the take-off parts provide rigidity and compensate for thermal expansion.

Thermally conductive elements fit into the floor structure so that the grooves match. During installation, a hacksaw or scissors for metal is not used, since the plates have convenient notches. The metal breaks off according to the marks to the required length and is put into the design position.

The plate is divided into sections:

- 4 pieces of 115 mm;

- 2 pieces of 135 mm;

- 1 part 270 mm.

Installation of thermoplates directly into the screed is allowed, but the heat will go down to warm up the concrete. A polystyrene backing with the foil layer facing down is laid on the surface before laying the system.

Heat exchangers work efficiently when mounted on an insulating material, such as extruded polystyrene foam or polystyrene. This limits the transfer of energy to the ceiling and heats the upper floor. Expanded polystyrene boards are used FT 20/45 or FT 20 / 45L, the density of the foam should be at least 30 kg / m3. Grooves are cut in the insulation using a gutter knife.

Plate Assignment

A metal thermoplate is used if it is not possible to make a traditional screed (buildings with wooden floors, foam block walls and others). Sometimes the height of the ceilings does not allow to raise the base to the thickness of the warm floor. The term of delivery of the object affects the choice of screed or dry laying method. Concrete is gaining strength for 28 days, and the system with thermoplates is ready to work after finishing laying the finish layer.

Heat-reflecting structures are an alternative to the water floor on a cement-sand base. The lightness of the design allows the use of elements on any floor, because the load increases slightly.

Water pipes are tightly clasped with metal in the groove and heat the element. Aluminum and steel belong to the group of effective heat conductors, therefore, they transfer energy to the floor covering. Convection in the form of flows and jets is completely absent, the surface heats up evenly. Heat is transferred more efficiently if the lateral parts of the thermoplate fit snugly against the base and top layer.

Specifications

To calculate the required amount of material, 4 to 6 plates are taken per square area.There are no turning parts in the product range. This is due to the fact that the heat transfer in these departments is negligible, and the price of the corner element will significantly increase the cost of the system. Pipes are laid out along the contour of "snake" or "snail".

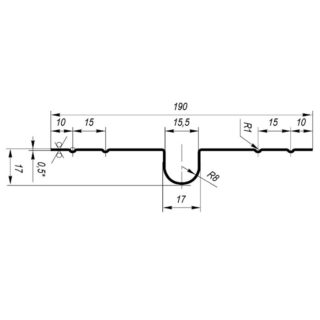

Indicators of plates for underfloor heating:

- element size along the length of 1 m;

- width - 130 or 110 mm;

- the groove is made under the pipe with a diameter of 16 mm;

- one product weighs 500 g.

The total weight of the heated floor is reduced by 5-7 times compared with the option on a concrete base. The system power is from 50 to 200 W / m2, the indicator varies depending on the type of floor finish, the installation pitch of the pipe (not less than 125 mm). Heat-reflecting elements transmit up to 94 - 95% of heat.

Advantages and disadvantages

Dry floor installation has advantages over traditional wet pipe laying. High thermal conductivity of the metal allows you to heat the surface in a short time.

Positive aspects of using thermoplates:

- the number of plates and the weight of the structure is easily calculated independently, because the step and weight of the plates are known;

- the system simply fits in with your own hands after drawing up a pipe layout plan;

- reduced load on the parts of the floor compared to wet options;

- the size of the room in height decreases slightly.

The disadvantage is that after turning off the boiler, the metal plates cool immediately, and the concrete keeps heat for some time. The cost of thermocouples is high, but with the wet method, additional materials are also purchased, and the complexity of the work increases.

Features of flush mounting water circuit

The system is mounted on a wooden or polystyrene base with grooves for arranging convex grooves of thermoplates. Laminate, carpet, parquet or tile are laid on a moisture-insulating layer. For waterproofing, polyethylene with a density of 200 microns is used.

The strips are laid out with an overlap of 10 - 15 cm and fastened with adhesive tape to each other, the perimeter is formed with a damper tape, glued to polyethylene and the wall. If a room with increased vaporization, such as a bathroom, is additionally put on a vapor barrier or a material with combined protection against moisture and steam is selected.

Isolation is performed 2 times:

- by the area of overlap before laying the insulation;

- on the surface of a mounted system of pipes and plates.

On sale there are solid plates without grooves for pipes, then the furrows are made independently. Plywood and a piece of pipe with a diameter of 16 mm are used. A groove is made in the sheet, the plate is superimposed on the plywood, and the gutter on the metal element is pressed through by a pipe. The edges of the thermoplate are aligned by improvised means.

The order of assembly of the warm floor:

- the coating is cleaned of debris and leveled with putty or a self-leveling mixture;

- the waterproofing layer is laid out;

- heat-insulating mats;

- grooves are made and heat distribution plates mounted;

- water pipes are laid;

- thermal insulation is placed between the grooves.

The second layer of hydroisol is mounted after checking the system's operability. Final flooring is done.

Features of wooden water floor heating

This type is arranged in a wooden house or dwelling with beamed ceilings made of natural material. The dry method involves a rack or modular stacking system. The first kind is done with the help of boards or bars, and the second uses ready-made blocks from fiberboard with ready-made grooves.

The supporting layer with a thickness of 20 mm is made of wood, the moisture content of which is not more than 6-10%.Hardwood boards should be 80 mm wide and up to 1200 mm long.

The composition of the construction of a warm floor on wood:

- base with a layer of waterproofing;

- boards, modules or bars laid out according to plan;

- pipe routing using plates;

- isolation from steam and humidity;

- gypsum fiber sheet with a thickness of 10 mm;

- flooring.

The boards can be laid in a continuous layer, but you will have to make a groove in each of them for the protrusion of the thermoplate. This method is laborious and expensive, because the wood is processed on a machine and at home there are not always conditions.

Another option is that the boards are laid out with a gap that corresponds in width and length to the convex groove of the plate. The base area under the warm floor is leveled out horizontally so as not to disrupt the energy carrier current.

Heat Distribution Plate Selection Criteria

The choice of products is to study the technical characteristics and parameters. It is believed that a large coefficient of thermal conductivity of the metal affects the efficiency of the system. But the degree of floor heating depends not only on the plate material. High heat capacity affects the regulatory equipment badly, because the heating rate will be high.

Heat transfer is affected by:

- layout system and pipe material - plastic give energy longer than metal;

- type of bottom insulation and compliance with the technology of its installation;

- the type of finish flooring - ceramics, laminate, heats up faster than linoleum-based or carpet.

The judgment that the plates are in a heated state and do not corrode is erroneous. During the operation of the house, household fumes penetrate through the finishing coatings onto the base and structure of the water floor. Condensate in a heated state acts more destructively.

Pay attention to the presence of an anti-corrosion layer on the surface of the heat-reflecting plate - then you can not put a layer of waterproofing when laying the system. The seller provides a quality certificate from the manufacturer to confirm the reliability of the product.

The choice is affected by the functionality of the room. When laying on polyurethane foam in the kitchen and bath, steel plates with an anti-corrosion layer are suitable. If the base is a concrete slab, copper or aluminum products will work better.

Scope of use

The pipe system with heat distribution elements is suitable for new and reconstructed buildings. The plates are quickly mounted and last a long time. Thermal distribution structures do not create problems in buildings with a weakened foundation, because they add a little weight to the ceiling.

Dirt and dust from the use of materials for concrete screed are eliminated and labor costs for installing a warm floor are reduced, therefore, dry laying is used in working offices, trading floors, workshops and residential buildings. To install the floor in one room, you do not need to close the company or organization.