Efficient, convenient and inexpensive heating in a private house with a solid fuel boiler is gradually replacing traditional gas and electric analogues. In addition to efficiency, this method of heating buildings is in demand among property owners who are not connected to central utilities. Devices can be used as the main and backup heat source. In small cottages, these devices simply cannot be dispensed with, since they will not allow their owners to freeze even in the most severe frosts. It is possible to carry out the installation of heating boilers with their own hands, without involving hired workers, and without obtaining permission. For the heating system to work efficiently and reliably, you need to study the types of heating equipment, its features and the range of fuel used.

Criteria for choosing a boiler in a private house

There are no unified recommendations regarding the characteristics of the heating system for a private house. Each building, as well as the priorities of the people living in it, is individual. However, there are a number of requirements that must be observed in all cases.

The following criteria apply to the selection of solid fuel boilers:

- The cost of equipment, components and installation work. You should not buy a cheap installation, as it is characterized by low productivity and unreliability.

- An assortment of solid fuels in the market. It is advisable to choose devices for fuel, which is always available and is inexpensive.

- Convenience of equipment operation. Ease of maintenance, repair and firebox.

- Efficiency of the boiler. The cost of producing a unit of energy.

- Possibility of storage and storage of selected fuel.

- Safety of equipment in terms of risk of fire, smoke and shutdown in case of malfunctions.

It is recommended that the issue of fuel choice be put at the forefront. It is necessary to calculate in advance how much the heating season will cost and only after that make the final decision. In addition, you need to measure your physical abilities and state of health during the operation of the heater. It will take effort to carry weights, go down the stairs with them, get up at night to refuel the furnace. And this is not for everyone.

Types of solid fuel boilers

By the level of functionality, heating devices are divided into the following types:

- Single-circuit. Used only for heating rooms.

- Bypass. They are used simultaneously for heating and creating hot water for domestic purposes. The liquid stock is contained in the heat accumulator, ensuring a uniform temperature of the water in the system.

Depending on the type of fuel used, boilers are made of steel or cast iron.

Traditional, direct burning

Products of this type have been used in space heating since mankind learned how to get metal. They are a chamber with windows for loading fuel and blowing. The material is laid on the grate, through which air enters and ash falls.

Advantages of traditional boilers:

- simplicity;

- reliability;

- affordable price;

- the ability to do it yourself;

- manufacturing options in different versions.

The disadvantage is that traditional furnaces are characterized by low productivity.Firewood burns out in them for several hours, you need regular refueling.

Pyrolysis

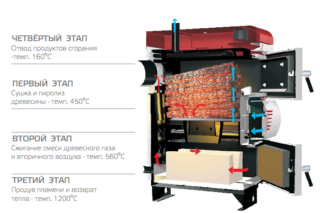

These are complex and expensive gas generating plants in which the combustion of fuel occurs in several stages. The first is drying and heating of wood. Then it ignites, gas is released, and firewood turns into coal. In the final phase, the gas ignites, and the coal continues to smolder. Air is supplied to the closed chamber by an electric fan.

Advantages of the device:

- high efficiency;

- combustion controllability;

- complete fuel processing;

- excellent heat dissipation.

The minus of the design is only in its cost. Despite this, the payback comes after the first heating season. In addition, the electric boiler is dependent on a constant current supply. In its absence, the fan stops and combustion stops.

Long burning

A feature of such a wood-burning stove is that the blower is located not from below, but from above. Thanks to this design, combustion occurs only at the upper level. The fire gradually descends as the wood is consumed.

Product Advantages:

- long burning;

- lack of frequent refueling;

- profitability;

- simplicity of construction;

- the ability to load a large amount of fuel.

The minus of the device of long burning is only in its size. To ensure the implementation of the principle of action, it is necessary to make furnaces of large height and diameter.

Pellet

The body of the device consists of two chambers. In the first, capsules are stored, and in the second, they are burned. Fuel is supplied automatically as it is consumed. Pellets pressed from waste wood are used as fuel.

Design Advantages:

- high heat dissipation;

- strong heat produced;

- long work at one gas station;

- inexpensive fuel;

- the presence of automation that provides control and security.

Minus products only in their price. Such devices are best chosen for those who do not want to work as a fireman for days on end. The hopper volume is enough for 24-48 hours of continuous operation.

Installation Instructions

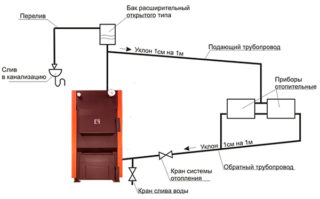

Having decided to make heating in a private house with his own hands, the solid fuel boiler needs to be installed correctly. The basic principle of the unit is the height difference between the lower and upper part of the water circuit. In addition, a high pipe is needed to create good traction. If the house has a strip foundation, it is advisable to use the basement level for equipment placement. If this is not possible, you will have to put it on the ground floor. To ensure good circulation of the coolant, you will need to install a small centrifugal pump.

Before starting installation work, it is necessary to prepare the room for the installation of the boiler.

The sequence of work is as follows:

- Remove all combustible objects.

- Make concrete a solid base for the device.

- Close wooden products with sheets of iron or asbestos cement.

- Arrange productive ventilation. It is necessary to foresee the likelihood of a power outage and make a supply and exhaust system operating on natural draft.

The best place to place the boiler is the side wall. From this place it is convenient to lead a pipeline and a chimney.

Installation of a heat generator and a chimney

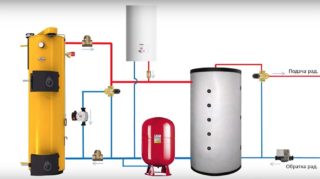

It is advisable to install a solid fuel boiler together with a buffer tank for warm water. This tank is placed between the furnace and the piping. You can connect it to the system at the construction stage or during the operation of the system.

Object purpose:

- System overheat protection. The reservoir absorbs superheated water, mixing it with relatively cold contents. This eliminates the possibility of a circuit break due to steam formation.

- Energy storage. The buffer collects heat and, as the carrier cools in the system, supplies hot water to it. In the presence of a two-peak meter, energy accumulates at night, when its cost is 2 times lower.

- Commutation. The device connects in a single circuit all connected units operating on gas, electricity and solid fuel. There is an energy distribution, smoothing of pressure and temperature drops.

To work, you need such tools and materials:

- roulette, level, square;

- puncher, screwdriver, grinder;

- hammer;

- soldering iron for plastic;

- polypropylene pipes and fittings;

- marker;

- safety glasses and gloves.

Installation of the heating system is carried out in the following sequence:

- Drawing a marking in accordance with the drawn up scheme.

- Strengthening the base for the boiler.

- Mounting clamps for pipes and stops for radiators.

- Installation of the furnace, its alignment and fixation.

- Pulling plastic pipes, installing taps and fittings.

- Check the tightness of the circuit.

- Arrangement of the chimney.

- Carrying out a control firebox.

A separate issue is the assembly of the exhaust system. It is made of steel pipes or sandwich sections. Depending on the architecture of the building, a choice is made in favor of the external or internal laying of the chimney. The internal version allows the use of heat from the chimney to heat the premises and the water circuit. External is good because you do not need to make holes in the ceilings and engage in waterproofing work.

Boiler connection diagram

The connection diagram of a solid fuel boiler is selected based on its capacity, number of floors and building area. Priority is given to single pipe or double pipe construction

The boiler CT can be connected in one of the following ways:

- closed loop line (Leningradka);

- with three-way valve;

- with underfloor heating and batteries;

- with a heating tank and storage tank.

When installing a heating system, each radiator should be supplemented with a Mayevsky tap for bleeding air, if it is not initially provided for by its design. In addition, it should be borne in mind that when heated, the water expands. To prevent the formation of high pressure in the system, it must be equipped with a sealed expansion tank.