Air heating in residential buildings is a prerequisite for comfort. To know how the heating scheme of a two-story house with forced circulation of the coolant is arranged, it is important already at the design stage. This will help save money and oversee the construction team. Small skills of the builder will allow you to implement a heating system yourself.

Construction principles

Heating schemes in two-story houses are built on the basis of common structural elements.

The composition must include:

- heating boiler: electric, gas, solid or liquid fuel;

- heat exchangers, radiators;

- piping system from the boiler to the batteries;

- automation and protection circuit;

- expansion tank;

- coolant;

- adjusting equipment.

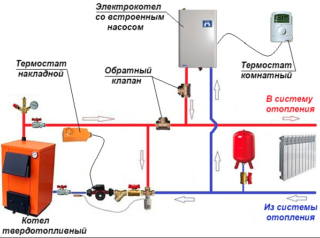

In modern gas and electric heaters, automation and an expansion tank are built into the structure. For solid state heaters make a protective harness.

Structural elements

There are boilers on sale that can operate on two types of fuel - in this case, electric tubular heaters (TENs) are built into the circuits of a gas or wood heater.

Automation of heaters allows restarting heating after shutdown without user intervention or in manual mode. Protection schemes timely shut off the energy supply during emergency operation (overheating of the coolant, overpressure in the system). Mandatory such devices in gas boilers. When shutting off, the valve closes and when the supply is resumed, gas will not enter the premises.

Pipelines are made of steel, copper, metal-plastic or polypropylene products. The latter option is preferable in terms of money costs; it saves installation time. For welding use inexpensive soldering irons, costing from 800 rubles. Fittings, adapters from plastic to metal thread are affordable.

An expansion tank is an essential element of the heating system. When heated, the water expands and the excess flows into the reserve tank.

If the inside of the device communicates with air, the circuit is called open. If the rubber membrane of the expansion tank is not connected to air, the circuits will be closed.

The strength of heat exchangers in a private house does not impose high requirements. The maximum pressure in the pipes does not exceed 2 - 3 bar. Such a pressure can withstand even pure aluminum radiators, which can be destroyed in central heating systems, where the pressure reaches 14-15 Atm.

Coolant selection

As a heat carrier, water or a special antifreeze is chosen. The first option is less expensive. Filling of pipes and radiators occurs through a tap from the water supply. Water as a coolant is justified in settlements with a constant supply of energy (gas, electricity). If interruptions are frequent and long - they refuse water. In the event of a shutdown for a long period in frost, it will freeze. Ice will destroy pipelines, radiators.

Do not pour water into the heating system of cottages that they visit infrequently. In addition to stopping the supply of energy, the boiler may stop heating water for other reasons. If you do not restart the heating in a timely manner, accidents are inevitable.

In summer, the system must not be allowed to empty - this will lead to corrosion or oxidation of the inner surface of the heat exchangers.

Antifreeze is expensive, but does not freeze in the cold, the minimum temperature is indicated on the package. Even if the antifreeze is cooled more strongly, it turns into a kind of loose snow, which will not lead to the destruction of radiators and the boiler. The concentrates are diluted with water in proportions according to the manufacturer's instructions.

When filling the system with non-freezing liquids, special pressure pumps are used. This is a drawback - it is desirable to have the device in personal use. Call the master to refuel 200 - 300 gr. evaporated or leaking liquid is financially expensive.

Antifreeze additives are included in the antifreeze recipe, which will preserve the inner surface of the pipes, radiators, boiler heat exchanger.

General principle of work

The operation scheme of any heating system is to convert the energy of a burned gas, solid (liquid) fuel or electricity into heat. Heated water (antifreeze) flows through pipes to radiators, where it transfers heat to space.

Gravity system

The laws of physics are at the core of functioning. If the contours provide for the natural movement of water, then such a scheme is called gravitational.

It is extremely difficult to make a floor heating circuit in gravity systems without the use of additional pumps. The difference in the pipes in the floor by several millimeters leads to airing and the cessation of the movement of the coolant.

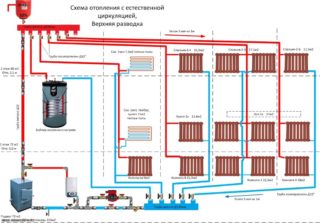

The density of the heated coolant is lower than that of cold. Due to the density difference, water / antifreeze from the boiler rises upwards along the supply riser (diameter 60 - 80 mm). In the upper part of the entire system, an expansion tank of open or closed type is installed.

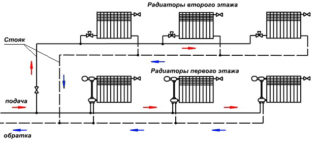

Along the perimeter of the premises of the second floor, lay the upper wiring loop. A pipe with a diameter of 40-50 mm is mounted with a slope of 2-3 cm per meter of length. In the places of installation of radiators, pipes with a diameter of 16 - 25 mm are welded into the wiring. On them, the liquid flows into the radiators. Then the coolant enters the batteries on the first floor.

At the level of the boiler or slightly lower along the perimeter of the building, a lower circuit (return) is laid into which chilled water is collected.

It is possible to equip a gravity circuit without additional pressure pumps at a height from the boiler to the upper distribution pipe of not more than 6 -7 m. This is the height of a two-story house.

The circuit finds application in places where the electricity needed to operate the pumps is often turned off. Gas boilers in this case are equipped with non-volatile safety devices.

The same scheme is needed for systems with solid fuel boilers. In the event of a power outage, the circulation stops, and the firewood / coal continues to heat the water. A solid fuel boiler can be stopped only by quickly removing burning fuel, which is extremely problematic. There is an increased pressure that can destroy pipes and radiators.

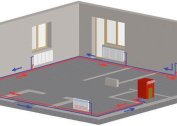

Forced Circuit Operation

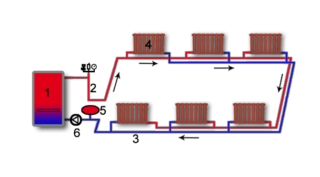

For forced movement of the coolant, circulation pumps are used.

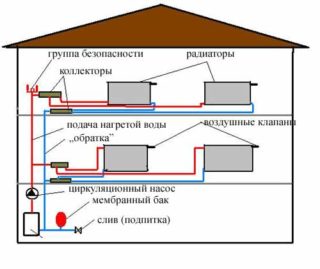

The pump is cut in at the junction of the "return" and the boiler - here the coolant is already cooled and the pump is operating in a gentle mode. At the outlet of the heater, the coolant temperature reaches 80 - 100 degrees, which sharply reduces the resource of the equipment. In boilers with an integrated pump, everything is connected in the correct way.

The water movement scheme works according to the following algorithm:

- After applying power, the pump is turned on and the coolant is set in motion.

- The boiler heats the water / antifreeze, and the pressure created by the pump squeezes the coolant into the circuits.

- Hot water is piped to the radiators, where it is cooled, heats the air and enters the "return" pipes.

- The process goes into a cyclic state.

Developed and put into practice different wiring diagrams, which are optimally suited for different operating conditions.

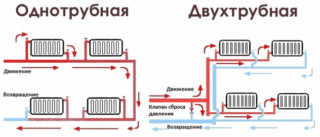

According to the principle of supply and collection of coolant, two types of structures are distinguished: one-and two-pipe. In the first case, the system is similar to gravitational. Through the supply pipe, the hot coolant is supplied to the radiators. The second pipe collects chilled water and returns it to the boiler. This option is used when replacing old boilers without pumps with new automatic models. The piping scheme in this case is not changed. The coolant along the riser is pumped to the second floor and then flows down.

Double pipe circuit

When arranging large buildings, it is precisely the two-pipe scheme that is used. Radiators are connected in parallel. According to the location of the supply pipes, schemes with upper and lower wiring are distinguished.

The radiator connection diagrams for the upper and lower wiring are indicated in the technical documentation. Incorrect connection causes airing or low efficiency of the device.

Double tube advantages:

- does not require complex calculations and selection of pipe diameters;

- independent adjustment of heat transfer of each radiator, which allows you to set the temperature in each room and save energy;

- simple setup and commissioning;

- the power of the pumps is small;

- there are no significant pressure losses at the beginning and end of the circuits;

- coolant temperature is approximately the same in all radiators of the circuit;

- by shutting off the supply and drain valves, the battery can be removed for replacement or repair without turning off all heating;

- minimum hydraulic resistance of pipelines.

The disadvantage is the increased consumption of pipes (for supply and return). Given the cost of polypropylene pipes, ease of installation and repair, this minus can be neglected.

Popular wiring diagrams for two-pipe heating systems: dead-end and Tichelman.

The deadlock scheme has another name - with the oncoming movement of the coolant. The scheme is divided into sections. A heated coolant flows through the pipe from the boiler to the farthest battery, which returns to the boiler through the return pipe. Ease of understanding gives popularity, but competent calculation and tuning of the system is required. The farther from the boiler, the thinner the pipes should be. After starting, each radiator is adjusted with shut-off valves. Improper adjustment may result in. That the entire coolant will pass through one radiator, the rest will remain cold.

The Tichelman loop works with the concurrent movement of the coolant. The wiring is carried out by pipes of the same diameter. The pressure and temperature of the coolant in each radiator are the same, which simplifies balancing. Regulators can precisely set the temperature in each individual room.

Requirements for the scheme:

- Contour length up to 35 m.

- On long sections, pipes of large diameters (40-60 mm) are used and thermostats are not installed, since they become useless.

- A perimeter longer than 30 m is divided into several zones and a beam wiring is mounted. She is also called collector. The cost of more pipes is offset by their smaller diameter. For the "power" of one radiator, a 16 mm pipe is enough.

Each radiator in this embodiment is easy to adjust to the desired heat dissipation.

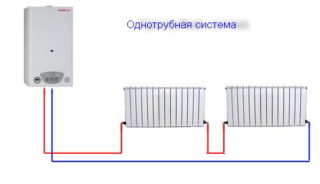

Single pipe schemes

Single-pipe heating schemes are optimal for single- and two-story buildings with up to 5 heating batteries in one circuit. A larger number will require fine tuning. Branching can reduce the pressure in the pipes and some radiators will not get enough to heat the coolant.

Schemes allow you to make upper or lower connection. In the second case, the pipeline can be hidden under the floor. Take into account that this will slightly reduce the heat transfer of radiators, so part of the energy is spent on heating the screed.

Single-tube options are made with an open or closed expansion tank.

The disadvantages of the scheme include difficulties in replacing radiators. To maintain operability, you must immediately install a jumper in place of the removed battery, otherwise the system configuration will be violated. For the same reason, bypasses from pipes of smaller diameter are mounted between the inlet and outlet of the heat exchanger.

One of the popular schemes is Leningradka. To connect, use a diagonal (cross) or side (one-sided) circuit.

Choosing radiators specify how the outputs for the connection are made - for the bottom or side. If necessary, purchase angle adapters. It is important to follow the manufacturer's recommendations.

Stages of equipment and operation

If a decision is made with one's own hands to make a house heating scheme in two floors, a sequence of work is strictly carried out.

- Calculation of the need for heat output of radiators for each individual room and total power. Information is needed to select the boiler and the number of batteries. Take into account the location of doors and windows relative to the cardinal points, the area and degree of insulation of the floor, walls, floors.

- Designing - general and floor, coordination of gas equipment installation sites with the supplying organization. Allocation of necessary electric power if electricity is used.

- Selection and purchase of a boiler, pipes, heat exchangers, components for assembling a single system.

- Piping.

- Assembly of a single circuit, crimping.

- The first launch and configuration, elimination of leaks.

During further operation in the operating mode, the following types of work are performed:

- cleaning all components from dust and dirt;

- timely elimination of leaks;

- airing radiators while lowering the temperature of individual devices;

- pressure check, timely replenishment of the coolant;

- maintaining the fluid level in the system throughout the year, including in the inter-flow period.

Knowing the possible schemes for equipping a two-story house with heating will help make the right choice, monitor the progress of installation work and in the future correctly respond to any malfunctions.