When preparing a heating system project, the task arises of choosing a pipeline. The parameters of the products used depend on the heat output of the boiler, the branching of communications, and the dimensions of the dwelling. To decide what is better to use - polypropylene or metal-plastic for heating and water supply, the study of the features of pipes made of these materials will help.

Criteria for choosing pipes for heating

Before considering the differences between polypropylene and metal-plastic pipes, it is worth listing the factors that determine the characteristics of the purchased products. The preferred diameter, materials and construction of the wires are determined by a number of parameters:

- open or closed communications;

- heating unit capacity, types of fuel used;

- communication installation methods;

- the nature of the circulation (forced or natural);

- dimensions of the heated home.

The temperature of the coolant, its stability and the pressure available in the system are also taken into account. Stable low temperature makes much less demands on pipes than the conditions in which water hammer and pressure drops often occur. The latter are characteristic of central heating, so it uses exclusively metallic communications.

For polypropylene

Compared with other plastic pipes, products from this material are characterized by the greatest rigidity and strength. Due to their low price and good performance, they have become very popular. But when purchasing such pipes, it should be remembered that there are different options for them, differing in their ability to withstand hot temperatures. There is no point in using PP-N and PP-V for heating: products of the first type are intended only for cold water supply, PP-B can also be used for warmer water, but its temperature should not exceed 50 degrees.

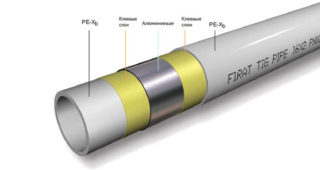

For heating systems, only PPRC pipes are permissible. Such products have a three-layer structure. The middle layer consists of reinforcing material. It can be fiberglass or aluminum. For heating, they buy products that can withstand water at 90-95 degrees. It is important that the inner walls are smooth and the thermal expansion is as low as possible.

The market is replete with polypropylene pipes with a high expansion rate, which easily deform when operating in high temperature conditions, so close attention should be paid to this.

For metal plastic

Metal pipes include aluminum and plastic components. The main criterion for the purchase of a heating system is the good tolerance of high temperatures. You should take pipes sharpened for continuous operation at a temperature of 95 degrees and able to withstand surges up to 110. Both diameter and wall thickness matter - they are selected in accordance with the design features of the system.

Material Comparison

When choosing metal-plastic pipes or polypropylene pipes for heating, the homeowner must represent the behavior of these materials during operation. Also, you must consider the requirements for the installation of different types of pipes.

Products made of metal-plastic well withstand hot fluid, without deforming or bursting.Able to serve in such conditions up to 50 years. For polypropylene pipes, such terms are real only for models with a reinforcing layer and a compatibility mark with boiling water. If at least once hot water is poured into a PP-B or PP-N pipe at a sufficiently high pressure, it will last a maximum of a couple of years after such an incident. These products were originally intended only for laying water pipes with low temperatures.

With regard to frost resistance, the characteristics of pipes made of these materials are identical: in no case should the coolant be frozen. Moreover, metal-plastic, showing superiority in most operational parameters, in this case is destroyed immediately. Polypropylene products are able to withstand the expansion caused by ice for a short time.

During a sharp temperature jump, metal-plastic products stick up due to different expansion rates of the constituent materials. This applies to freezing and the sudden supply of hotter water. In the first case, the weld of the metal part may even burst. Polypropylene expands and the pipes sag. If they abut against the wall, the pipeline may collapse. This is important to take into account during installation: the communications device should include sliding supports.

With a limited budget, the price category often becomes the main one when choosing polypropylene or metal-plastic pipes. The first material wins - the price of products from it is 2-3 times lower. Furniture also differs in cheapness, which cannot be said for that for metal plastic: the pipes made of it are quite acceptable for the budget, but the mounting parts are very expensive.

The advantages of polypropylene include its elasticity, due to which the communications remain airtight even after the water frozen in them begins to thaw. Reinforced versions are resistant to mechanical stress and have a large wall thickness. The material is not susceptible to corrosion and is not destroyed by the low quality of the coolant, has dielectric properties. It is very lightweight, which simplifies transportation and installation. On sale you can find accessories of various configurations for laying communications, including those including pipes from other materials.

The main disadvantage of this plastic in terms of installation is the lack of flexibility. Even to create a small rotation of the circuit, you need to weld the outlet elements or adapters. If a certain section of the communication is damaged, it must be completely replaced: it is impossible to repair the welded joint. When carrying out installation work, this must be taken into account: before and after a potentially problematic unit (for example, a fitting or crane), even fragments are left so that you can cut the unit and embed a new one. Also, with poor-quality welding of joints, there is a risk that with a sharp increase in temperature, the plastic will melt and block the path to the coolant. In the absence of experience in laying such communications, it is better to entrust the work to the masters. Definitely, polypropylene should not be used for central heating: the material does not tolerate the sharp changes in temperature and pressure inherent in this system.

Plastic, on the contrary, is flexible and able to hold the shape that it was given. However, there will be problems with small radii - trying to bend the pipe in this way can break it. It is better not to bend manually, but use spring parts or a pipe bender. The latter provides a smooth configuration. Also, the smoothness of the inner walls, which creates the best circulation, and the good tolerance of the hot coolant are also pluses.

The main disadvantage of metal plastic is the unsatisfactory behavior when freezing water: the walls are easily torn.

Features of pipe installation

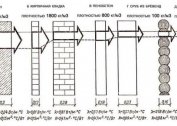

When preparing for laying, we must not forget that polypropylene pipes are not used in warm floors and other closed structures (for example, hidden in the thickness of the wall). Due to thermal elongation, conditions are not suitable for them when connection control is not possible. Mount polypropylene at an ambient temperature of at least + 10 degrees.

Primary requirements

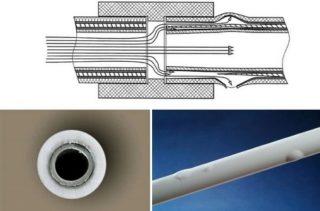

Plastic pipes are connected using fittings and a diffuse welding machine. Using such a tool will create tight joints. But handling it requires agility and skill: if there is a shortage of those, it is better to invite a master.

A reliable method of joining metal-plastic pipes is crimping by means of fittings and a tick-borne tool. It is recommended for use in enclosed structures. The collet method of connection using plumbing keys is also used.

Reviews of professionals

Konstantin, heating specialist. Most polypropylene pipes are suitable for cold water supply, and operation in heating will lead to deformation and melting of the material. In a private house, in the absence of pronounced jumps in pressure and temperature, a wiring is made of reinforced polypropylene with a marking indicating suitability for such tasks. But metalplastic is better.

Andrey, the builder. Polypropylene is easily deformed from hot water, and, on the contrary, is more resistant to freezing than metal-plastic. Polypropylene also has a high coefficient of linear expansion. The flexibility also wins metal.

With regard to reliability, flexibility, withstanding deviating heat carrier parameters, metal-plastic products show the best results. If it is impossible to allocate funds for such products, reinforced polypropylene is used if the heating characteristics are suitable for its operation.