Various types of containers are reusable containers designed for the transport of goods by rail, road or sea. Often it is made as a swap body of a long-distance truck. Depending on their direct purpose, containers are divided into universal and special. The main problem that arises during their preparation for operation is proper warming in order to preserve the transported goods or create comfortable living conditions.

Container device

Before insulating the container inside, you will need to familiarize yourself with the features of its design. According to the drawings given in the project documentation for the product, the frame consists of the following main elements:

- upper and lower frame bases;

- set of racks (corner, medium and for doors);

- set of wall shields;

- outer skin.

The lower frame is made in the form of a welded unit, consisting of 2 longitudinal and transverse channels. The front beam in the area of the doorway is additionally reinforced with a metal bar. The welded upper frame consists of 2 longitudinal and four transverse beams, the joints of which are reinforced with scarves. From above and from the sides, the frame of the container is sheathed with sheets of steel 1.5 mm thick, on which the insulation itself is mounted.

Marine analogue device

The design of products of this class is not much different from the usual. Its base is the same strong steel frame, welded from longitudinal and transverse channels. The top of the container is made in the form of transverse and longitudinal beams. Around the entire perimeter, the frame is sheathed with steel sheets, characterized by good anti-corrosion properties and having a corrugated profile. In the manufacture of shipping containers at 20, 40, 45 feet high quality alloy steel is used. Its thickness is 1.5-2.0 mm, which ensures a strong and rigid structure.

Materials and Tools Required

To organize and implement insulation of the sea container from the inside, you will need to prepare:

- insulation material of the selected type (polystyrene foam, for example);

- wooden beam 5x5 cm and dowels;

- adhesive tape, primer and plastic wrap;

- polyurethane foam, paint and sealant.

In addition, it is necessary to purchase plasterboard sheets, as well as blanks of particleboard or fiberboard.

Of the large tools, a grinder, an electric drill and a screwdriver will be required. In addition, you need to prepare the following toolkit:

- screwdrivers;

- yardstick;

- device for applying foam and sealant;

- dowels;

- brush, hammer, sharp knife and construction level.

You will also need a pencil or colored marker for marking.

When working, you should use hand and face skin protection - a respiratory mask, gloves and glasses.

How to insulate the ceiling and walls

One of the best materials that can be used to insulate surfaces with a wavy structure is polyurethane foam, which well conceals even large irregularities. The attractiveness of this insulation is due to its following advantages:

- ease of installation of the material;

- environmental friendliness;

- tightness to walls (without formation of cracks);

- reliable thermal insulation.

The use of materials of this class reduces convective flows and virtually eliminates the possibility of condensation. In addition, extruded polystyrene foam is used to warm the sea container for living. This material is not inferior in its performance to polyurethane foam, differing from it only in price.

It is possible to insulate a container for housing with ordinary mineral wool, but its use is limited in conditions of high humidity (in sea containers, for example). In the presence of moisture vapor, this insulation material quickly saturates and begins to decay over time.

The order of work

The process of turning a conventional steel duct into a warm container involves several steps. Before warming the container for permanent residence, preparatory measures will be required. In advance, it is necessary to determine the method of isolation (outside or inside).

Preparatory stage

The essence of the preparation is to carefully examine the container for signs of dirt and rust on its surfaces. The first ones are simply washed off with water, and traces of corrosion, if possible, are cleaned in any convenient way. Usually, a grinder with a nozzle in the form of a metal brush is used for this. Remove traces of rust from the outside and inside, after which they proceed to coating the metal with a layer of protective primer.

After the soil has dried (after about 2 hours), you can proceed to painting the surfaces, which allows you to reliably protect the metal from moisture and damage. A second coat is applied to the dried paint. Upon completion of these procedures, they proceed to the main insulation operations.

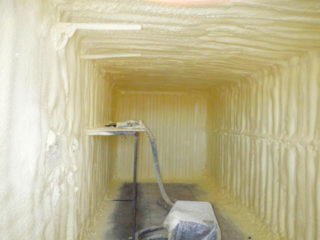

Stages of internal work

Insulation of the container from the inside is possible when the loss of part of the volume of the internal space does not matter. The work carried out in this case is divided into two stages: finishing of the side surfaces and thermal insulation of the ceiling. When carrying them out, the walls should first be insulated. To do this, a wooden crate is mounted on them, consisting of bars of a suitable size. Then, in the intervals between them, the plates of the selected heat insulator (expanded polystyrene, for example) are laid. To enhance the effect of isolation from cold air masses, it is additionally pasted with a layer of penofol.

The ceilings are insulated in the same way as the walls, after which everything is sheathed with plasterboard sheets.

If it is planned to install a furnace inside the structure, it should be borne in mind that polystyrene foam and polyurethane foam do not tolerate high temperatures. Therefore, their contact areas with heated surfaces will need to be insulated with glass wool gaskets.

Floor insulation

To insulate the floor in a residential container, you need to carry out the following work:

- A dense plastic film is laid on the base, providing full steam insulation.

- A thermal insulation layer formed on the basis of foam, for example, is arranged on top.

- Before laying it, a frame is made of bars (logs), stacked across the container with a step equal to about 60-70 cm.

- A set of self-tapping screws is used to fasten the bars, screwed into each board in at least 3-4 places.

- The insulation is placed in the gaps between the logs so that it fills them to the entire height of the beam and is distributed as densely as possible.

- The remaining gaps must be sealed with foam.

The material is covered with a 10 mm thick multi-layer moisture-proof plywood, which protects the heat insulator from deformation and damage.

Before arranging skirting boards, all gaps around the perimeter of the genital base are treated with sealant or polyurethane foam.

Features of external insulation

Insulation of the house from containers outside is in demand in situations where it is important to maintain their internal volume without any changes. For outdoor work, foamed polystyrene is usually used, which protects the metal well from corrosion, or thick sheets of foam. In the second case, for fastening the material, special hardware (“umbrellas”) will be required, the use of which threatens the formation of cold bridges. This lack of material is necessarily taken into account when warming, for which risk zones are additionally treated with liquid heat insulators or sealed with foam.