Existing standards for underfloor heating require their arrangement in the screed flooring, which allows to obtain a reliable system with high thermal efficiency. However, sometimes it becomes necessary to build such a structure in houses with wooden (parquet) floors, where screed is basically impossible. There is a technical solution that allows you to equip a heated water floor without screed in frame and other buildings where floors are not designed for increased loads.

Advantages of a floor without screed

When arranging a warm floor without screed, its owner receives the following advantages:

- Upon completion of installation work, light and durable structures are obtained that provide high thermal efficiency.

- The approach allows you to save on the space occupied by the heating system - the layer thickness does not exceed 2-4 cm.

- Leaks are eliminated very simply, since access to the pipes with the carrier is unlimited, as is the case with the screed.

- When using special heat-dissipating plates, the return from the water floor increases sharply, and the heated rooms themselves warm up faster.

Automation control systems without screed are easier than other types of underfloor heating. Assembly does not take much time. The latter is explained by the lack of need to prepare a concrete mortar and wait until it dries. There are no drawbacks to such designs, apart from the high cost.

Types of underfloor heating systems

Depending on the base material, there are two ways of arranging a water heated floor: on polystyrene tiles or on wooden flooring. Regardless of which one is selected as the main one, before starting work, the bearing base should be carefully leveled: remove all existing bumps and update rotten boards.

When choosing the first method, you will first need to prepare a mounting scheme for polystyrene blanks. When compiling it, it is important to take into account the dimensions of the room and choose the dimensions of the tiles correctly, immediately cutting them at the place of installation. They are fastened by means of special clamps included in the delivery set of insulation material.

- On wood flooring

- In polystyrene boards

Materials used

Immediately before laying the heating water floors in a wooden house, the bases themselves are reliably insulated. Therefore, at the preparatory stage, you will have to select the following groups of components:

- brand of insulation;

- material of water conduits (pipes);

- type and brand of insulation plates.

Heat insulators

Of the materials known and accessible to the user for insulation of heating structures, basalt (stone) cotton wool is optimally suited. The heat insulator is permeable to water vapor and combines well with wood, allowing it to "breathe" and prevent rot. On the other hand, when installing mineral wool, it is important to provide conditions for the removal of vapors, as otherwise it becomes wet and loses its heat-insulating properties.

Of the materials known and accessible to the user for insulation of heating structures, basalt (stone) cotton wool is optimally suited. The heat insulator is permeable to water vapor and combines well with wood, allowing it to "breathe" and prevent rot. On the other hand, when installing mineral wool, it is important to provide conditions for the removal of vapors, as otherwise it becomes wet and loses its heat-insulating properties.

For insulation of coatings on the first floors, it is recommended to use heaters based on it with a density of 40-80 kg / m³ and a thickness of up to 200 mm. For interfloor ceilings, the same material with a thickness of 50-100 mm is quite suitable. In this case, its task is expanding and, in addition to thermal insulation, supplemented by obtaining good sound insulation.

Thermal insulation based on polymers, which include polystyrene foam, expanded polystyrene (PPS), and also foamed polyethylene almost do not allow moisture to pass through.When using them, the rules for laying plates should be observed, since in case of violations of the technology, the wood at the points of contact with the polymer will begin to blacken and then rot.

Pipes for underfloor heating

When choosing pipes laid on floor mats without a screed, the following points must be taken into account:

- Pipe products with a diameter of 16 and 20 mm are selected.

- The most suitable materials are cross-linked polyethylene, metallized plastic and copper. Preference is given to polymer products based on SP.

High-quality polyethylene pipes from well-known manufacturers are no cheaper than samples made of metal-plastic and almost not inferior to them in terms of performance. There is no fundamental difference between the individual types of polymer products, for warm floors they are equally good.

Copper pipes are noticeably more expensive, and a lot of effort and time is spent on their installation. But in terms of thermal efficiency, none of the known materials can be compared with copper. The only thing that draws attention in this case is the inadmissibility of their use complete with aluminum distribution plates. These metals are incompatible in their chemical structure, due to which the contact zone oxidizes with time and then collapses.

Distribution plates

Since the thermal conductivity of aluminum-based workpieces is higher than that of steel products, this material is most often used in their manufacture (with the exception of wiring from copper pipes). At the same time, you should know that good aluminum plates are much more expensive than their galvanized counterparts (about 1.5-4 times). The observed variation in prices is associated with different thicknesses of plate blanks. Therefore, experts advise choosing thick-walled plates that can accumulate and then give off thermal energy for heat removal.

Flexible corrugated pipes made on the basis of stainless steel stand out from modern technological materials. They are durable and mounted without welding or soldering. In addition, during operation, these products transfer heat well, which allows them to be used in lightweight flooring structures.

Contouring Methods

When arranging the contours of the water floor, three laying schemes are traditionally used: a spiral, a snake and a double snake. The choice is determined by the design features of the apartment and the ease of installation of the piping system.

Spiral (snail)

This installation method is the most common and most effective in terms of energy consumption. During its implementation, pipes are laid along the perimeter of the room, starting from the walls and towards the center (with a decrease in radius). Then the track is laid in the opposite direction. The main advantage of this scheme is the uniformity of heating the room by eliminating thermal “dips”.

You can choose an arbitrary pitch of pipe laying, starting with the smallest of 10 mm. The snail scheme allows you to equip a heating system in rooms of any shape and area. With its help, it is possible to make one large loop covering the room or several smaller turns bypassing large furniture, for example.

Snake and double snake

The method of laying with a snake is to arrange individual threads of the floor with large loops. It is suitable for rooms that need to be divided into functional zones with its own temperature regime. The route for laying the first loop is along the perimeter of the room, after which a single snake is launched from the inside.For this reason, a well-heated coolant circulates in one half of it, and slightly cooled in the other half, which on average provides the required uniformity of heating. When using the double snake scheme, the media supply and discharge circuits are located next to each other throughout the room.

Mounting technology

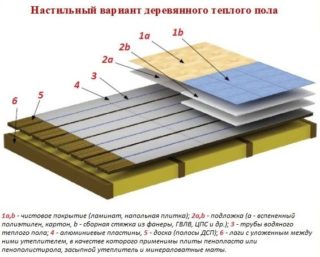

When installing a heated floor without a screed under linoleum, it is allowed to use an insulating structure made of polystyrene sheets as a base. Typical panels for warm water floors without screed are sold in the form of plates 3 cm thick. If necessary, reinforce the rough flooring, it is allowed to lay a foam backing under them. After that, heat-distributing plates should be fixed on the surface of the heat insulator, in the grooves of which the pipes themselves are mounted. On top of them rolled material is laid, which is the substrate for the finish coating (laminate or parquet).

On a wooden base

When implementing this method, first, on a draft base (boards), wooden logs are mounted, between which heat and waterproofing mats are laid. The resulting structure is closed with wood slabs, leaving thermal gaps of about 2 cm on the walls. They are fastened to each other by means of special clamps. All further operations on arranging a warm floor without screed are carried out according to the same scheme as when using polystyrene sheets as a base.