Extruded polystyrene carbon is the best choice for thermal insulation of buildings for any purpose. The design parameters and properties of the material can effectively solve the problem of energy conservation in all areas of construction: from the base to the roof. The insulation is designed for both private use and industrial.

Production Specificity and Properties

The material is produced in an extruder: polystyrene granules, together with a blowing agent, are heated and then extruded. A gas mixture serves as an additive, which allows one to obtain an ecological high-quality building material as a result. As a result of extrusion, a material with a uniform design in the form of closed cells of size 0.1 - 0.2 mm is obtained.

The insulation with a frame and small pores is characterized by excellent strength, has a long service life. After a while, it does not condense. It must be remembered that the degree of thermal conductivity and moisture absorption of the insulation are determined by the coefficients. The latter, in comparison with similar materials for their intended purpose, have low values. The main disadvantage of Carbon is flammability, although harmful toxic substances are not released as a result of the fire.

Closed insulation cells contribute to minimal water absorption, so the material does not swell in a humid environment. Expanded polystyrene Carbon is not amenable to the process of decay, is distinguished by chemical resistance, is not damaged by biological exposure. Due to its light weight, it does not create a load on the structure, it is easy to work with it. They are produced in the form of plates, the thickness of which is 3 - 100 mm.

Specifications

Carbon insulation is famous for its high mechanical strength, due to which it is successfully used for thermal insulation of the foundation, ground floor, roofs.

Technical specifications:

- thermal conductivity coefficient - 0.029 W / mk;

- the coefficient of steam conductivity is 0.01 mg / mchPa;

- the moisture absorption level when immersed in full for 1 day - 0.2% of the total size of the insulation;

- modulus of elasticity - 17 MPa;

- density - 25-32 kg / m³;

- combustibility class - G3-G4;

Based on manufacturer's guarantees, the service life of Carbon insulation is 50 years. At the same time, during the period of operation, thermal insulation properties are preserved.

Advantages of Carbon insulation

The material is widely used in construction, due to its many advantages:

- significant thermal insulation efficiency;

- environmental friendliness;

- preservation of properties during operation;

- durability;

- strength;

- minimum moisture absorption;

- resistance to biological and chemical effects;

- low weight.

XPS Technonikol plates can be stored under a canopy that protects from solar radiation and heavy rainfall. This material should be folded onto the coasters. Short-term presence in an open area in the package is allowed to protect against external influences.

Application area

Extruded polystyrene foam slabs are successfully used to insulate individual parts of the building.

Foundation protection

The insulation system of the base of the structure significantly increases its reliability and durability. The main problem that has a negative effect on the foundation is freezing and swelling of the soil.It is solved after warming the soil around the entire perimeter of the construction. The use of Carbon Prof extruded polystyrene foam in the construction of the blind area allows you to get rid of freezing of soils at the base, since such a heat-insulating material has stable thermal performance and extremely high compressive strength.

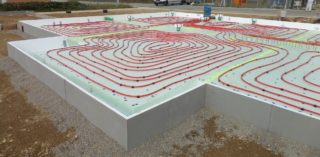

Soundproofing floors and floors

Among Carbon heaters there are materials with a density above 250 kg / m³. Such polystyrene foam is suitable for soundproofing any floor, as well as floors. A good option for such purposes is XPS TechnoNicol Carbon Eco insulation.

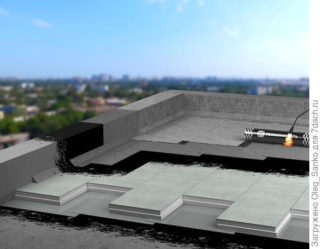

Roof insulation

Thermal insulation of the roof avoids the penetration of cold on the rafters, create comfortable conditions in the house. Thermal insulation boards are recommended to be laid over the rafters. Variants are possible when plates of extruded polystyrene foam are attached to the rafters from the inside, but then the inter-rafter space is also filled. The thickness of the insulation layer is determined by local climatic conditions.

Insulation made of extruded polystyrene foam Carbon is the best option for insulation material for rooms for which saving space is important.

Mounting Features

The use of extruded carbon fiber polystyrene foam will be effective if the following rules are followed during installation:

- For thermal insulation of the foundation, the use of Carbon Drain polystyrene is considered ideal, since there are grooves on its outside that water can drain off. The insulation is attached to the mastic layer. Slabs located in the ground do not need to be coated. For the lower floor, decorative plaster is required.

- Installation of heat-insulating plates on the walls of the building occurs with the use of glue, which is squeezed out in the form of dots or stripes. Additional fixation is done with dowels. Consumption - 4-5 pieces per Carbon stove. After laying the insulation sheets, the seams must be blown out with foam, later apply a protective layer of putty. For strength, a reinforcing mesh is installed under the solution.

- Floor insulation is often used for the basement of houses. The plates are laid after pressing the sand-crushed stone base and covering the last layer of waterproofing. The joints are glued with tape, which eliminates the ingress of cement into the gaps of XPS sheets. At the last stage, two layers of drywall are fixed or a screed is made.

- The thermal insulation of the roof with Carbon slabs begins with waterproofing. The insulation is laid on the prepared canvas, and then they are wrapped with ballast, which is often used as gravel.

Transportation of XPS TechnoNIKOL slabs is allowed only at a distance of up to 500 km. For this, open vehicles are used, which necessarily have protection from atmospheric precipitation and sun exposure.

Variety of Carbon Materials

For the prompt construction of high-quality thermal insulation, based on the main requirements of users, the well-known company Technonikol produces several types of extruded polystyrene foam.

- Carbon Solid - plates are designed for traffic interchanges, foundation insulation, roofs. Such material does not absorb moisture. Density index - 50-60 kg / m3, reliability for compression - 700 MPa.

- Carbon Prof - during manufacture, graphite particles are included in the foam, which gives the material reliability and negligible thermal conductivity (among types of Carbon). Expanded polystyrene XPS Carbon Prof 300 is used by professionals for thermal insulation of shopping centers, residential buildings. Such slabs are also used to isolate a ground floor, foundation.If the name contains the RF marking, such products are additionally treated with flame retardants, which increase fire protection.

- Carbon Prof Slope - using a set of similar plates you can create a roofing slope of 1.7 - 8.3%. The use of a heat insulator provides the opportunity to establish a drain of water in addition to lighting devices, ventilation systems.

- Heater Technonikol Carbon Eco - provides excellent thermal insulation, excellent protection against moisture. Ecological cleanliness contributes to its widespread use in installation works. Material safety has been proven in the laboratory. In the manufacturing process, this type of extruded foam is filled with nanocarbon, which gives the products a silver color and additional benefits when insulating objects. For construction products with the additional designation FAS, the surface is rough, which significantly improves the quality of the connection with putty. Accurate excavation along the perimeter of the plates to some extent simplifies installation, eliminates cold bridges. The inclusion of a flame retardant in the composite mixture eliminates the risk of ignition of the thermal insulation. Insulation is often used for insulation of the facades of suburban mansions.

Products with the SP mark are considered sophisticated to create Swedish plate designs. The ECO SP insulator makes it possible to quickly perform installation, as a result of which to reduce the heat loss of the foundation. The thickness of the insulation boards Carbon Technonikol allows for long-term thermal insulation of the base. In order to withstand the possible load, a compression reliability of 400 kPa is provided. Building products with zero moisture absorption are suitable for landscaping drainage, redirecting groundwater after heavy rainfall.

Carbon extruded polystyrene foam - high-quality and effective thermal insulation, which allows you to save heating costs, provides reliable and long-term insulation of almost all building structures.