From the correct thermal insulation directly depends on how comfortable the atmosphere inside the room will be. In the cold season, the optimum level of heat should remain, in the summer - cool. It is important to study in advance the available types of insulation and find out which is best suited for a particular purpose, depending on the type of work. It is necessary to take into account their scope and determine the pros and cons of materials from leading manufacturers.

Types of insulation

Materials for thermal insulation are divided into several categories according to type and purpose. They differ from each other in shape and appearance. They are also divided into two types according to the type of raw material, taking into account which they can be organic and inorganic. What is the best insulation for home, decide after studying the characteristics of the most common types.

Foiled

Foil insulation for walls, pipes and other elements is easy to install and low cost. It is supplemented with a layer of aluminum or metal polypropylene, due to which it has reflective properties. The efficiency of insulation can reach 97%. This is a wear-resistant material that can be used as a waterproofing.

Foiled insulation does not allow cold wind, is completely isolated from external influences and does not deform in the event of sudden changes in temperature. Isolon is not susceptible to rot and mold. It is considered thin material, but more effective compared to others. Among the disadvantages, the need to use adhesive compositions for fixing in order to create a warm layer from the inside or outside is noted.

Tiled

A mineral plate or plate insulation from other materials should be selected depending on the purpose. Plates can be used to insulate ceilings, floors, roofs, attics and walls, as well as the outer parts of wall ceilings. Simplicity of installation makes it possible to work with plates without resorting to the help of specialists and without using expensive special equipment. Plate standard insulation should not be in contact with water, so it needs good hydro and vapor barrier. Most plate heaters are quite strong and durable. They can have different thicknesses - the larger it is, the warmer the coating will be.

Among modern stoves, it is better to choose environmentally friendly non-combustible options without toxic and dangerous components.

Liquid

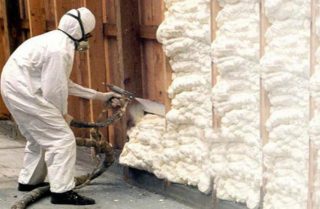

The category of liquid options includes heaters, which are a substance that can harden after installation and turn into a strong porous layer. Liquid insulation with a thickness of a millimeter in its properties can be equated to a layer of traditional block insulation, for example, mineral wool, foam or glass wool.

When comparing liquid heat insulation materials for walls, it is worth choosing the most popular options, for example, polystyrene foam, ceramic compositions or ecowool of a sprayed type. They can be used in construction and for surface treatment of equipment in order to eliminate corrosion. Most often they are used to insulate walls from the outside, ceiling, floor and roof, as well as metal pipes.

The choice of insulation for the intended purpose

The main task of any insulation is to reduce heat loss in winter and to reduce the heating of structures in the summer. Thanks to the correctly selected material, the building elements will be reliably protected from the penetration of cold air, the formation of condensate, mold and rot.Insulation materials help prevent deformation of elements of any structure and increase its service life. The scope of their application includes insulation of ceilings, floors, external and external walls, foundations, roofs and attics.

For foundations

The foundation is often subjected to severe stress, moisture and temperature extremes. In the winter period, moisture accumulates in it, the material is destroyed, cold air penetrates through the cracks. The foundation needs heaters of the Pro category with a low level of thermal conductivity, waterproof, quite durable and resistant to environmental influences.

Mineral wool insulation should not be considered as a suitable option, they quickly accumulate moisture and lose their basic properties, are not too resistant to mechanical stress. It is better to give preference to polymer insulation, devoid of these shortcomings. The ideal option is polystyrene foam extruded type or polyurethane foam.

For basement ceilings

Basement ceilings must be insulated to preserve their durability and increase the level of reliability. The material for the basement should be as strong and resistant to stress as possible, not absorb water, be frost resistant. An important factor is the environmentally friendly use and safety. To insulate the socles, it is better to use tiled extruded polystyrene foam, rigid polyurethane foam or hard rubber on a bitumen basis.

For exterior walls

Insulation for exterior walls is primarily selected on the principle of reliability and durability. The most effective option is basalt mineral wool, which can hold its shape for a long time. It does not thin out, does not condense, and does not cake. Also, a foam will be a good choice, while you need to take into account its dimensions.

Before buying material, you need to know the dew point indicator. In places where it is exceeded, the insulation will need to be laid in several layers.

- Styrofoam for plinth

- Penoplex for the foundation

- Mineral wool for walls

For the attic

The lack of insulation in the attic provokes the outflow of a large amount of heat, lowering the temperature in the room and an increase in heating costs. The attic or attic insulation is selected according to technical characteristics, calculating the required amount and laying it according to special technology. For the attic, both natural and artificial material are suitable. It can be mineral wool, polystyrene foam, polystyrene or polystyrene foam, polyurethane foam or bulk expanded clay.

For the roof

To choose the right insulation for the roof, first of all, its thermal insulation qualities are taken into account. The best material has a low level of thermal conductivity, optimal density indicators to avoid possible overloads of the rafter system. The material for the roof should not absorb moisture well, which is especially important when installing the roof. It is better to choose a thermal insulation that will ideally fulfill its functions both in the cold and in the warm season. It is important to pay attention to fire safety indicators - the insulation should have an ideal level of resistance to fire and be as non-combustible as possible.

For the floor

When choosing a heater for the floor, you should choose a material that can withstand the maximum pressure on it, as well as the ability to maintain thermal insulation qualities when exposed to moisture. Expanded clay is most often used for this purpose, if it can be used during the pouring of a concrete floor. If there is a basement in a brick or wooden house, for insulation of the floor the insulation is fixed from the side of the basement. An ideal option would be polystyrene foam or a foam block with optimal properties.

- Expanded clay

- Slaggy

- Glass wool for the roof

Factors determining the choice of insulation

During the construction of modern houses, great attention is paid to the choice of material for thermal insulation. Mistakes in choosing provoke an increase in utility costs and great inconvenience in the cold season. A lot of heaters are presented on the construction market, which differ in price, installation method and technical parameters. First of all, the consumer should pay attention to such parameters:

- coefficient of thermal conductivity: the lower it is, the better the material is able to retain heat indoors;

- safety, environmental friendliness, resistance to fire, mold and rot, environmental factors;

- cost taking into account the costs of other construction materials;

- vapor permeability and the ability to pass moisture particles through itself;

- block size, shrinkage and weight, the ability not to lose volume under its own weight;

- hygroscopicity and moisture absorption;

- ease of installation;

- Colour.

When using insulation suitable for all indicators for walls or ceilings, it is possible to minimize possible costs and reduce costs during repairs.

Rating of the best manufacturers

When choosing a heater, it is worthwhile to study in advance the advantages and disadvantages of materials from the most famous manufacturers on the market. The rating includes heaters, divided into categories depending on the source material.

- Basaltic - Rockwool and Hotrock Smart.

- Styrofoam - Technopol XPS Technoplex and Penoplex Comfort.

- Foam - Knauf Therm House and PSB S-15-O.

- Fiberglass - Isover Warm House and URSA Geo.

- From polyester fiber - Shelter Ecostroy ShES Arctic.

Since there is no universal insulation suitable for all structural elements, when choosing a material, it is important to study in detail its characteristics and installation features. Experts recommend taking into account the material from which the structure or building itself and its additional elements are made, since heaters of completely different categories are suitable for brick, aerated concrete and expanded clay concrete walls.