Equipping the interior of housing, some homeowners think about their own hearth. The presence of live fire in the room has a beneficial effect on the internal atmosphere and gives a feeling of comfort. Often the choice falls on fireplaces, the design of which looks very dignified and modern. But there are no less decorative designs of fire chambers, and at the same time more functional. We are talking about a certain group of heating equipment, which was called - a brick fireplace stove.

The advantages of a fireplace stove

The universal structure has the features and properties of both a stove and a fireplace. In fact, this is a monoblock, inside of which lies a flue gas exhaust channel. The structure has a firebox with a sight glass and a stove for cooking. For the designer’s imagination, there are large open spaces, because there are practically no restrictions in size, shape and cladding. Strict requirements only in the correct observance of internal proportions.

Practical technical advantages:

- Room heating occurs quickly if the ratio of the focus and area of the room is proportionate.

- You can individually use a firebox or stovetop in structures where they are not combined.

- The efficiency for equipment of this type reaches 80%.

- The facilities are easy to maintain, as all fire chambers are equipped with ash-pots.

If the fireplace stove is professionally arranged and the materials correspond to thermal loads, such a unit can last several decades.

Even a well-made heating device requires the use of good fuel, otherwise no one can guarantee a long operation.

Place for the fireplace

The location of the brick fireplace for a house on wood depends on the preferences of the owner and the tasks that she will perform. At the planning stage of the building, it is necessary to consider where the heating device will stand and take into account all the necessary conditions for this.

It is possible to build a furnace against an external wall. In this case, it will only heat the room in which it is located, and the neighboring ones, if it is not planned to hang doors on the interior openings. The option is suitable for small guest houses or country cottages, where the fireplace is a decorative and functional element of the kitchen-living room. Of the technical aspects, it is necessary to provide a foundation (it should not be rigidly connected with the foundation of the bearing wall), a layer of thermal insulation that will prevent heat from going out through the wall to the outside, and the connection of the chimney to the external pipe.

Another case is the installation on two sides, when one part goes, for example, into the guest room, and the second with a stovetop - into the kitchen. This option is practical, because in any case, when the device is in operation, a larger amount of space is covered, and the smell of the prepared food will be cut off from the rest area of people. From the point of view of cost savings, the location is convenient, since you can only spend money on decorating the hearth from the side of the room, on the other hand, limit yourself to neat masonry. If a monolithic slab is not provided for in the house, a reinforced concrete foundation must be poured under the structure and the insulation of the firebox from the wall should be considered, if the latter is made of combustible materials.

In one-room houses with the main spacious room, you can put the stove in the middle, then the heat will be evenly distributed around the entire perimeter and effectively heat the structure.

Design calculation

A fireplace stove for heating a house refers to a type of structure that is not done by eye, each size here matters. The question does not concern the scenery (you can clad the heater as you like), but only the main working elements of the structure:

- firebox;

- ashpit;

- chimneys.

An exception is products where heat-resistant bricks are also facade bricks - 100% proportions are required here. There are many cases when ignoring such recommendations resulted in shifting the entire array after testing the focus on performance.

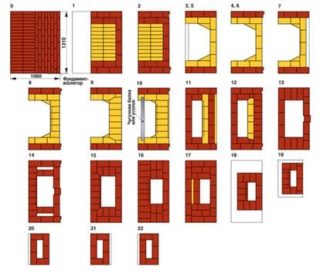

Any fireplace stove is laid out according to a certain pattern. There are a lot of such drawings, it is easy to calculate their installation on them. For the reference point, take the linear dimensions of the selected scheme, which they adapt to their existing building clinker - they proportionally increase or decrease them. The drawing involves the ordinal visualization of the masonry. After calculating the amount of material in each row, they go to the total number of the masonry worker on the supporting parts, refractory to the furnace, and also determine the need for steel lintels and plates.

Necessary tools and materials for construction

Tool that will be needed for the construction of the furnace:

- Mason's trowel for applying mortar to the masonry plane;

- Pavilion level and plumb to comply with the vertical and horizontal position of the rows and walls of the building;

- steel square and pencil, necessary for marking parts of the clinker for cutting;

- a grinder with a winning circle and a metal cutting disc for cutting concrete structures and steel strips;

- measuring tape;

- a bucket to serve the solution and the container for mixing;

- a rubber hammer for tapping clinker after laying on a solution;

- pliers and nippers needed when cutting reinforcing mesh;

- construction twine for stretching the front line of the wall raising.

The construction of a fireplace stove is a more responsible task than just walls, so measuring instruments must be checked without fail.

Brick is used as the main building element for masonry. Most often, these are ordinary varieties obtained from clay, or variants of futor material. All mixtures are suitable for ligaments, based on which clay of a refractory brand is used. Also required is sheet steel about 3 mm thick, metal strips, corners, nails and masonry mesh.

Fireclay bricks in the construction of furnaces are indispensable materials. This is due to their high heat resistance. Elements are used to organize the furnace space, less often as facade. Clinker brick due to its large mass and density is more suitable for the construction of the foundation for installation. The figured one already goes on facing when creating a certain decorative look.

DIY brick fireplace

The manufacture of a furnace device from clinker is a task for an experienced craftsman in this matter. The difficulty lies not so much in observing the sequence of construction of the masonry, but in the exact exposure of the proportions of the furnace, ash pan, the configuration of the chimney and all its transitions. But if there are no professional skills, you can try to build a stove yourself. It is important to choose a working diagram and leisurely display it line by line.

Double sided design

For beginners in the furnace business, you can consider simple double-sided fireplace stoves - devices with a through firebox.The advantage of this structure can be considered the ability to heat two adjacent rooms at once. There are no intricate moves with turns and inclinations with a certain angle - the chimney goes straight up, passing from the smoke collecting hood to the pipe along the trapezoid.

An easy-to-implement double-sided fireplace stove consists of the following elements:

- base - foundation poured from concrete or laid out of stone;

- ashpit zone - a wide part or sole of the heating device, where there is a niche closed on both sides with blower doors;

- the grate group, which is the dividing element between the firewood burning area and the ash collection site;

- a through furnace compartment, where on both sides there are glass fireproof doors or a door on one side and a stove on the other;

- smoke collection compartment for accumulation of combustion products;

- trumpet.

A small deviation from the proportions will not lead to the fact that the fireplace stove will not work. It is important to pay special attention to the ratio of the size of the furnace and the superfluous space for smoke collection. The volume of the elements should be approximately the same or a smoke extraction hood may be slightly increased. The latter also in its upper part should resemble a trapezoid in shape, the upper base of which is the entrance to the pipe.

Small construction

A brick fireplace stove on one hob of the hob is also not difficult to make with your own hands. It is a square-shaped firebox 2.5 bricks in length, where there is an ashpit with a door below, in the middle part there is a glass door for laying firewood (through which you can observe a burning flame), the top cover ends with a cast-iron stove with circles. In such a structure, you do not even need to lay out the pipe. The chimney is represented by a channel to the side of the furnace, which is connected to an external metal or galvanized pipe.

It is not necessary to talk about the high decorative capabilities of such a wood-burning heating device because of its simplicity, but if you pick up high-grade refractory material and perform the work carefully, perfectly observing the level, having done the jointing, you can achieve an attractive appearance.

Brickwork - sequence

The initial stages of laying the foundation and preparing the refractory mortar should be carried out in advance. Workflow ordering:

- The bottom row is laid out on the roofing material, exposing the clinker with a rub. The area of coverage should correspond to the size of the bottom sole with the exception of the thickness of the facing material.

- The installation of the blower follows. The door can be of different sizes in length, but it is desirable that its height does not exceed the height of the fourth row of the structure. All these levels are laid out, forming a niche inside for the accumulation of ash.

- The next fifth line of fireclay is the ash pan overlapping plane and the base for installing the grate group; the furnace compartment begins with it. With her help they make a ledge forward.

- After installing the grate, the following four levels up to and including 9 erect a firebox. One of the walls of this compartment (usually the front one) is a metal frame with a cast-iron or glass door installed in it. This is an observation window and an entrance for laying firewood.

- If the design provides for an open version, the furnace continues to be erected to the twentieth row and somewhere around 16, 18 rows the base of the mirror is mounted.

- Next, they switch to the vertical installation of chamotte and make a slight tilt with extension into the structure. This narrowing continues to be done to level 21.

- The next two elevation lines form the so-called chimney tooth, which protrudes 20 cm forward inside the firebox, after which the other two lines go to the shelf device.

- Then the smoke collector begins to form, the back wall of which runs smoothly, and the front wall narrows like a trapezoid to the size of the pipe passage. This translational narrowing is carried out in approximately 9 of the following orders.

The subsequent masonry is the construction of a brick chimney, each row of which has the same dimensions with respect to the internal section for the passage of smoke. At the junction between the smoke collector and the chimney, it is necessary to install a smoke damper, which can be a retractable or rotary type with a control knob brought out.

All construction activities for the erection of the furnace structure must be carried out by controlling the vertical elevation angles using a plumb line. Large deviations are unacceptable here, which will complicate the further lining.