Gas heating is the most effective way to heat rooms in industrial facilities and in the private sector. Heat generators are characterized by high performance and compares favorably with their counterparts operating on electricity, heat and liquid fuel. Gas equipment is manufactured in an expensive and budget version, with various functions and a wide range of power output. To achieve the most effective result, you need to familiarize yourself with the varieties of household heating appliances, their technical characteristics, pluses and minuses, installation rules, operation and maintenance.

Advantages and disadvantages of gas heating

The principle of operation of devices operating on natural fuel is simple and understandable. The water in the heat exchanger under the influence of a flame heats up, after which it begins to circulate through the system. The movement is carried out by gravity or a low-power centrifugal pump. Passing through the piping, the liquid gives off heat, returns to the boiler, after which the cycle repeats. If an apartment or a country house has been without owners for a long time and is not heated, antifreeze is poured into the system.

Gas heating at home has the following advantages:

- Ecological cleanliness. When burning fuel, only water vapor is formed, which is completely safe for humans and the environment.

- High heat dissipation. Natural raw materials emit a large amount of energy, far superior to traditional raw materials - firewood and coal.

- Profitability. Today, gas heating is much cheaper than all other energy sources used to maintain heat in private buildings. This is facilitated by huge reserves of natural resources and a developed system for their transportation.

- Fire safety. Burning takes place in closed chambers, fire contact with interior items is excluded. Setting the fuel supply system limits its flow and disables it in case of emergency.

- Autonomy. Modern electronic devices make it possible to turn the boiler on and off, lower and raise the temperature in the rooms in accordance with a given program.

- Functionality. Various models are used not only for the organization of heating, but also for heating water for domestic needs.

- A wide selection of devices that vary in size, cost, power and the availability of additional options.

- Choice of connection options. The source of gas may be a central highway, gas tank or standard household refillable cylinders.

- The ability to install the system with your own hands. To do this, you must have a set of household tools and purchase several inexpensive special devices.

Disadvantages of gas heating systems are few. Large primary costs will be required due to the high cost of quality equipment. If a choice is made in favor of connecting to a central network, you will have to obtain technical specifications and wait for their approval by the management company. Connection, periodic checks and maintenance will only be carried out by specialists. This is also a financial expense.

Calculation of gas consumption for heating a house

Calculation of fuel consumption for heating a building should be carried out at the design stage.This is necessary in order to install equipment and lay communications before the moment of interior decoration.

The following factors affect the consumption of a gas mixture:

- Boiler efficiency;

- installation power;

- climate of the region;

- structural properties of the building;

- height and area of the building;

- number of windows and doors;

- the quality of the thermal insulation of the walls, floor, ceiling and attic;

- Chimney design choice, internal or external.

When buying a heat generator, you need to consider that the maximum power is indicated in the passport, which should not be confused with the working one. This indicator is always 20-30% below the nominal. Maximum capabilities come in handy when lowering the temperature to an extreme level.

The following methods for calculating the volume of gas for heating a building are:

- By heat loss. The initial indicator is half of this value, after which 10% is added to it for heat outflow through the chimney and evaporation in the expansion tank. This will provide information on fuel consumption per hour. Then you need to translate it into hours, days and months.

- By volume. The average consumption is 30-40 watts of energy per 1 cubic meter. After calculations, it is necessary to translate the volume into specific heat released by different brands of gas during combustion. It should be noted that the Siberian G25 emits 20% more heat than the Volga G20.

- By area. The initial unit is 100 W per square meter with a standard ceiling height of 250 cm. At the same time, it decreases to 75 W / m2 for the southern and rises to 200 W / m2 for the northern regions.

- By electronic calculator. The resource is available on many, including free sites. It is enough to enter the requested data and wait for the result. To it should be added 20% for the error and extreme cold.

If to summarize the above examples, to heat a one-story house or cottage with an area of up to 100 m2, a boiler with a capacity of 8-10 kW is needed. To warm a well-insulated 2-story mansion, you need to take a good heater for 15-20 kW.

Selection and types of gas boilers

Technology does not stand still, so many gas boilers with sets of functions that suit any buyer have appeared on sale. Products differ according to the criteria that are taken into account when arranging all types of houses, depending on their configuration and methods of supplying fuel.

According to the degree of functionality, boilers are divided into the following types:

- Single-circuit. The coolant is used exclusively for space heating. It circulates in a closed circuit, consisting of strapping and radiators.

- Bypass. In devices of this type, two insulated heat exchangers are installed. One is designed to heat the house, and the second to create a reserve of hot water in the boiler, which has a layout in the bathroom, outdoor shower and kitchen.

At the place of attachment:

- Wall mounted. They belong to the category of compact ones, they are selected when the room is cramped or the interior conditions require it. In most cases, such devices are single-circuit, so they are hidden in niches or combined with cabinets of the same size. This achieves a seamless environment without loss of functionality.

- Floor standing. Products are more powerful, so they weigh more. They need more space, and sometimes a separate room. As a rule, floor models are dual-circuit; in connection with the consumption of a large amount of fuel, they need a direct vertical chimney. Designs are equipped with cast-iron heat exchangers, which makes it possible, in the absence of gas, to switch to solid and liquid fuel.

By air intake options:

- Atmospheric. The combustion process takes place in an open chamber, air enters it directly from the room.The evolved gas is discharged through a plastic chimney to the street due to the difference in temperature and pressure. Due to the optimal composition of the mixture, gas consumption is low, but the oxygen level drops, which negatively affects well-being. In addition, in the absence of fresh air, the flame may go out. The room must be equipped with forced-air and exhaust ventilation.

- Turbocharged. This design has a closed combustion chamber, where air is pumped by a turbine from the street. Turbine boilers are completely safe, they can be installed not only in the basement, but also on residential floors. In wall-mounted devices, combustion chambers are made of copper, and in floor-mounted ones made of cast iron. These materials are more resistant to fire than steel, and make it possible to develop high power. Double-circuit structures have a summer mode of operation, when only water is heated for domestic purposes.

When choosing a installation for heating a building, you should pay attention to the possibility of disassembling and servicing it with your own hands. The bottom line is that heat exchangers need regular cleaning and flushing. The services of specialists are expensive, it makes sense to save on them.

Self-Mounted Gas Heating Options

It is necessary to responsibly draw up a heating scheme for a private house with a gas boiler. The choice of an overly powerful device will lead to an excessive consumption of fuel, and a unit with low capabilities will work to the limit, which will lead to its rapid deterioration and failure. After compiling the design documentation, it is necessary to coordinate it with the gas company. Only after obtaining permission and technical specifications on hand can you start work.

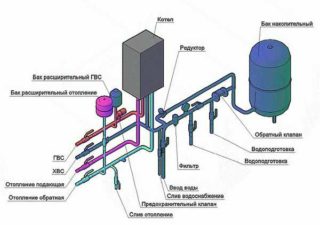

The scheme of the heating system in a private house from a gas boiler includes the following elements:

- Water heating unit. Its installation location and the order of fixing on the bearing surface are determined.

- Radiators Traditional cast-iron sectional batteries or modern aluminum products of an improved form are chosen.

- Wiring. To dissolve heating, a single-pipe or two-pipe version is used. The diagonal, lateral, lower or upper scheme for supplying pipes to radiators is selected.

- Centrifugal pump. The product is installed in the highway when an arrangement of a building of large height and area is carried out. The pump ensures the circulation of the liquid and prevents its stagnation in the final sections of the piping.

- Heat accumulator. It is a tank in which heated water is collected. It performs the function of a storage of warm liquid and compensates for the temperature difference in the system.

- Expansion tank closed or open. Accepts excess water when its thermal expansion occurs.

- Valves for bleeding air. System airing is a common occurrence. To eliminate it, end radiators are equipped with manual valves.

- The system is underfloor heating. It is equipped in those rooms that are tiled. Depending on the configuration of the room, the circuits are connected via bypass or operate in gravity mode.

- Automation. Devices that control the temperature of the coolant, turn on and off the boiler are connected to the system.

Additionally, sensors and devices are installed to ensure the safe operation of the equipment.

The correct step-by-step plan for arranging gas heating in a private house consists of the following stages:

- making calculations, purchasing materials, tools and devices;

- marking in accordance with the technical conditions;

- installation and fixing of a heating boiler, connection of a chimney;

- installation of an additional heating circuit;

- suspension of radiators, heat accumulator and expansion tank;

- production of strapping, its connection to batteries and tanks;

- connection and connection of a gas line;

- filling the system with water;

- conducting a trial run.

You can use the equipment after drawing up the act and sealing the meter.

Alternative heating methods

Since water heating is expensive and complex, you can choose one of the available types of appliances that run on gas. To make the right choice, you must first study their technical description.

To heat a private house, you can use:

- Convectors. Only gas is supplied to them, and it is allowed to connect household cylinders.

- Infrared emitters. Products are suspended from the ceiling and work on the principle of solar radiation. With limited power, they can quickly heat a large room.

When designing gas heating, it should be borne in mind that this energy source is much cheaper than electricity, solid and liquid fuels.