The construction of a stove or fireplace in the house with your own hands is a process that requires certain skills and knowledge. During the construction of furnace equipment, it is important to choose a suitable mortar for masonry, the quality of which directly depends on the reliability and proper functioning of the entire structure. The solution for laying the furnace is divided into several types, each of which has its own characteristics and features. It is important to choose the right category of solution depending on the type of work and prepare it taking into account the indicated proportions.

Types of mortar for masonry furnace

The kiln solution for standard masonry is a mixture of a binder and a special aggregate, which is filled with water. Such a mixture hardens after laying and binds together individual blocks, stones and bricks. The strength of the substance depends on the quality of the solution, which must be selected depending on the type of material. Quality varies with the components contained, they are divided into two categories: binders and fillers. The density of the solution is controlled using water added during kneading. The preparation of the mixture should be carried out according to the rules, if the mixture is of poor quality, it is easy to determine by the condition of the furnace:

- the presence of cracks in the joints of the masonry, which are formed in places of maximum heating;

- smoke entering the room;

- shattered bricks, blocks or stones of which the furnace is made.

When using low-quality mortar, the owner of the furnace will subsequently have to repair individual items of equipment and repair the cracks.

For chimney

The standard solution for the furnace cannot be used for laying the chimney, since during operation it is subjected to severe thermal and chemical stress. Refractory mixtures that are resistant to acids and can withstand extremely high temperatures can be used for this purpose. It is better to choose compounds that are optimal in terms of fat content, which include several components. These can be cement-based mixtures with lime or sand. It is important to pay attention to the density indicators of the composition, the finished mixture should be as uniform as possible and have a creamy consistency.

For foundation

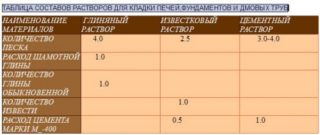

To build the foundation of the furnace equipment, clay mixtures made of red or white clay mixed with sand are most often used. The components are thoroughly cleaned of impurities, achieving their homogeneity, the standard mixture contains 1 part clay and 2 parts sand or vice versa. The main criterion for the finished solution is its fat content, on which the astringent properties of the mixture, its uniformity and, accordingly, the reliability of the future foundation will depend. Too soft a solution can provoke the formation of cracks in the masonry, the liquid will not make the design reliable enough. An ideal choice would be an elastic and quick-drying clay mixture with the addition of sand.

Other

To create the base and cladding, the clay solution for the standard furnace, consisting of clay and water, is most often used. Sometimes auxiliary components are added to it, for example, shavings, sawdust or building sand. Sand-cement mortar is advisable to apply with the goal of leveling irregularities on the surface of the equipment and for its lining.

A mixture based on one cement is used to seal joints during foundation laying.The lime mixture is recommended for use during plastering, as well as pipe laying.

Varieties and characteristics of solutions

The solution for any stove must meet standard requirements. This list includes thermal stability, ensuring the safety of equipment and the ability to operate it in full mode. The correct mixture should also be flexible enough so that cracks do not form on the walls of the structure. All mixtures are divided into types by components, among them there are options based on gypsum, lime, cement, as well as mixed options.

Types of solutions:

- heat-resistant, characterized by good resistance to high temperatures and retaining their chemical properties after drying without deformation;

- heat-resistant, which do not expand and do not change their properties during heating, they are more resistant to thermal deformations in comparison with heat-resistant analogues, ideally hold dynamic and static loads;

- refractory, can be both heat-resistant and heat-resistant, in addition to high temperatures, they can withstand the effects of aggressive chemicals contained in the exhaust gases.

When erecting brick and other furnace equipment, including one that does not heat above 400 degrees, only heat-resistant and fire-resistant solutions of the masonry type should be used. Using ordinary building mixtures in such cases is dangerous, the destruction of the chimney or other elements can lead to a fire.

How to mix the solution

The mixture used for work should be made as high quality as possible, since the strength of the finished masonry depends on it in many ways. It traditionally includes the main aggregate, water, as well as one or more binders, complex solutions contain at least two of these components.

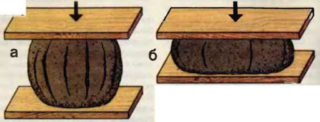

In the work, mixtures with an average level of plasticity are used, where the binder and filler correspond to the norm. They are able to give a minimum of shrinkage, are characterized by a high level of strength and do not crack. Too liquid mixtures are not suitable, since they are not strong enough and plastic, greasy can crack after drying. The amount of water should match the required consistency. It must be remembered that ready-made solutions are stored only in closed form to avoid contaminants.

Clay sand

To prepare a clay-sand solution, it is enough to soak the right amount of clay for 1-2 days. After that, pre-sifted sand is poured on the wooden shield by a bed and the required amount of clay is placed in the dug groove. It is covered with sand from the edges, then mixed with a shovel, breaking lumps and large pieces to obtain a perfectly homogeneous solution. A bed is formed from the resulting mass up to a height of 20-25 cm and a width of 30-35 cm, then it is divided into equal parts with a shovel.

To prepare a clay-sand solution, it is enough to soak the right amount of clay for 1-2 days. After that, pre-sifted sand is poured on the wooden shield by a bed and the required amount of clay is placed in the dug groove. It is covered with sand from the edges, then mixed with a shovel, breaking lumps and large pieces to obtain a perfectly homogeneous solution. A bed is formed from the resulting mass up to a height of 20-25 cm and a width of 30-35 cm, then it is divided into equal parts with a shovel.

Clay should be completely mixed with sand. After adding water to the mass to dilute it to a pasty consistency, the thickness of the joints when working with such a solution usually reaches 1 cm. Clay solutions have low strength characteristics, in the wet state this indicator reaches 2 kg / cm2, in the dry it varies from 4 to 8 kg / cm2. To increase strength, 1 liter of Portland cement or 100-250 g of ordinary salt is added to the bucket of the solution.

To make a quality clay mixture, all components are thoroughly mixed. If there is an excess of cement in the mass, cracks can form in the masonry joints over time. The presence of cement in acceptable proportions makes the solution more ductile and increases its strength.

Refractory

In order not to purchase the finished mixture for laying a refractory stove made of brick or other materials, you can prepare it yourself. Fireclay solution is prepared from crushed refractory clay and quartz sand, it will have a high level of fire resistance and ultimate gas density. It must be borne in mind that it is not suitable for masonry on the street and has a short shelf life, but is able to restore all its properties after mixing with water.

The heat resistance index of chamotte refractory mortar is higher in comparison with analogues, such a mixture is able to withstand up to 1200-1300 degrees. Experts recommend choosing it to create a chimney and a furnace zone, mixing with clay in a ratio of one to one. Solutions with refractory clay are also used for cladding, which can be carried out no earlier than four weeks after the operation of the furnace for a bathhouse or at home.

Clay

Sometimes to work with some elements of the furnace you need to knead the simplest solution, consisting of clay and water. It should be sufficiently fatty, viscous and thick, so for it you need to choose carefully sifted clay. The uniqueness of clay lies in the high strength acquired after firing, it is also resistant to high temperatures and provides an ideal grip for the entire structure. To make a standard composition, clay and water are taken in equal proportions, which can be changed in one direction or another, depending on the variety of the main component. Clay is mixed with water to an ideal creamy consistency and a wooden plank is lowered there. An ideal composition leaves a layer with a thickness of no more than 2 mm on a wooden surface.

Lime

Some compounds can successfully replace clay ones, including a solution based on lime. It must be borne in mind that it can not be used for all components of the structure, but only for the chimney, foundation, pipe and the first rows of masonry. The lime mixture is suitable for plastering furnaces, as well as for working with those parts of the building that do not heat up to temperatures above 450-500 degrees. The composition of slaked lime is more durable than clay, it is characterized by optimal moisture resistance and strength, has a low gas density. It can be used for cladding outdoor outdoor parts of the structure located in the open air.

How to cook with your own hands

The process of preparing the masonry mixture should take place according to the rules and taking into account the characteristics of the selected components that make up the solution. You can cook any mixture yourself at home, following the instructions.

An example is the manufacturing process of one of the most popular types of mortar - lime. For it, you need 1 part lime in the form of dough in combination with 2-3 parts sand. Before preparing the solution, the dough is filtered through a sieve and mixed with sieved sand, then water is added and all components are thoroughly mixed. Fresh lime mortar is able to maintain its properties throughout the day. To increase its strength, cement is added to the composition, to reduce the time for hardening, gypsum is additionally put.

The lime-based solution is distinguished by the level of fat content, to determine it, the finished mixture is mixed with a wooden spatula for several minutes and then look at the degree of adhesion. The liquid solution will not stick to the base of the scapula, the greasy one will cover it with a dense layer, the normal one will lie partially or in a thinner layer. An ideal option would be a mixture with the optimal level of fat content.To change its degree there is added lime dough or sand in order to increase or decrease the fat content of the prepared solution.

A correctly selected mortar for bricklaying a brick or other materials should have an optimal level of heat resistance, withstand various temperature differences without the risk of loss of strength and cracking. A suitable mixture should be selected taking into account the type of elements of the furnace equipment, as well as the permissible thermal loads.

- A solution of any type should resemble thick sour cream in consistency. Its quality is checked by laying several bricks. If the solution is too thin, the joints will not fill completely.

- It is necessary to test the main component, for example, clay, without relying on the specified proportions.

- Do not abuse additives for mixtures, in some cases additives or plasticizers, ash, terracotta and other components are added to the solution. They are used to improve the frost resistance or hydrophobicity of the joints.

- Masonry mortar is not used at temperatures below 5-8 degrees, the finished mixture must withstand the maximum recommended values.

You can check the quality of the furnace solution both at the stage of preparation, and after at home. The fat content of any clay depends on the depth of its occurrence - the deeper, the more liquid the solution will turn out. You can check this by touch, a small part of the material is soaked with water to the state of plasticine.

If the composition crumbles after adding fluid, the clay is too thin, it should not be used. At home, you can make two clay billets by taking half a liter of dried clay and 100-150 ml of water. Two balls of the same size are molded from the mass and dried for 2-3 days. After drying, check the quality of the clay for defects.