A house cannot be considered comfortable if it lacks a high-quality and reliable heating system. Kuznetsov's furnaces solve the problems of heating and cooking in homes and summer cottages, where it is impossible to supply gas, and the power supply is unstable. Along with the positive qualities of Kuznetsovka, they are not without drawbacks. This should be remembered when choosing domed stove options.

Design features and principle of operation

In a duct furnace, hot air moves in the direction from the furnace to the chimney. At the same time, the walls of the structure are heated, from which heat is radiated to the premises. In such wood-fired heating structures, the products of combustion are naturally removed. The better the draft, the faster the hot air is vented outside. The efficiency of the device reaches no more than 60%. Up to 40% of heat “heats” the surrounding space.

The channel models are cumbersome, the heating is uneven - in the initial section (while the air is hot) the walls warm up more strongly, at the end of the chimney less. The temperature difference often leads to cracks in the structure of the walls.

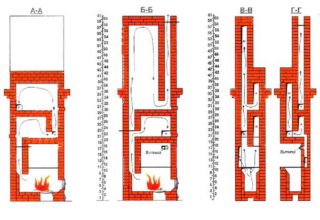

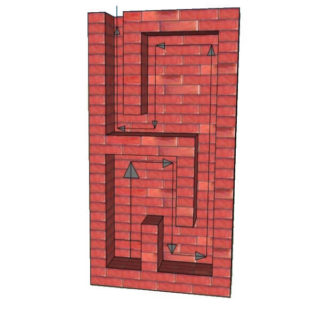

Kuznetsov stoves use a different method of removing hot combustion products. On his way, arrange one or several caps in which air exchange occurs.

Chambers communicate through narrow slots called “dry joints”.

The lower hood is integrated with the firebox. Under the "dome" due to the laws of physics, hot air accumulates, which heats the walls of the furnace, while cooling itself. As the fuel burns, a new portion of heat enters the cap, displacing the cooled mass down. Cooled air flows into the second dome, where the process repeats.

Depending on the volume to be heated in the room, there may be several caps; they are placed one above the other vertically. There are models where the domes are next to each other in the horizontal plane.

Pros and cons of Kuznetsov furnaces

Advantages and disadvantages are inherent in any designs for heating. Choosing a bell-shaped construction option, take into account the positive properties:

- Fewer bricks in the building, since the domes are hollow.

- Blacksmiths are smaller in mass, and the foundation is simpler.

- The efficiency of dome models reaches 80%, which will save fuel.

- Kuznetsov's furnaces are built with different configurations of domes (in the horizontal and vertical planes), so you can heat tall houses and spacious one-story housing.

- The voids in the masonry and thin walls warm up faster than classic Russian stoves. At the same time, hot air is stored in the domes, and does not leave through the chimney, so the blacksmiths cool down for a long time.

- In the second compartment, you can install a heat exchanger for water. There is no direct contact between the flame and the walls of the heat exchanger, which eliminates the burning of metal. As a tank for heating water, you can use a metal or aluminum tank.

- An additional damper puts the device into summer use - the second and third hoods are excluded from the process, and the oven can only be used in cooking mode, without heating the air in the room.

At the same time, dome furnaces are not without drawbacks:

- Construction is more expensive due to the greater payment for the work of the masters.

- The complexity and configuration of the channels complicates the cleaning of soot and soot.

- Impressive geometric dimensions for powerful models.

- Fast heating requires an increased consumption of firewood, some of which at the initial stages does not completely burn out.

- According to owners, the service life is limited to 15 years.

The construction of a dome oven begins only after a thorough analysis of all the pros and cons of the design.

Varieties for various purposes

Igor Kuznetsov and his team created a large number of universal and specialized models. Some are intended only for heating rooms, others are supplemented with elements for cooking or heating water. Fireplaces are allocated in a separate direction.

Drawings of tried-and-tested options are available on the inventor’s website. For convenience, alphanumeric designations are assigned to the structures.

Heating

Various options for the layout of the domes allow designs to heat one- and two-story houses.

Heating models are abbreviated as OIC (heating I. Kuznetsova). You can find options with a firebox located inside the room or in the utility room.

For a change and to give the necessary qualities there are stoves supplemented with warm stove benches (OIK-6 lie. And OIK 19 lie) and seats (OIK-7s).

Some units have an oven. In this case, the letter D is added to the code designation, for example, OIK-5D.

Heating includes stoves with a built-in fireplace.

RTIC models (Russian heating pot I. Kuznetsova) are needed for heating large rooms. They are massive, need a strong foundation.

Fireplace Options

Fireplaces, in addition to the heating function, play the role of decorating the interior. The firebox in this case is open, the fire can be observed visually. The furnaces are equipped with a firebox for ordinary heating, which can be located on the facade, from the right, left side, or behind.

For construction, they choose an option in which it is convenient to service the stove from the utility room or hallway - you do not have to carry firewood to the living room. Work with waste (ash) also does not imply the inevitable dirt in the room when cleaning the ash pan and blew it from the hallway.

OIC-K variants with stove benches, built-in ovens and a corner fireplace have been developed.

Boilers

To organize the water heating circuit, options have been developed with the designation KIK (I. Kuznetsov's boiler). A steel heat exchanger is integrated in the second dome. Water circulates through the system through an electric pump.

Models are designed for power 16, 17, 34 and 64 kW. The first option (16 kW) is equipped with a hob.

Heating and cooking

Universal heating and cooking stoves are designed for homes with a year-round stay. The model is equipped with hobs and ovens, shelves for heating food and water.

The furnace can be located on the front or side, which allows you to choose an option for any interior option.

Optional installation of a stove bench is offered. For large rooms make long fireboxes, which allows the use of large-caliber firewood. They burn longer, toss up fuel less often.

The size of the hob depends on the composition of the family. For 2-3 people choose a reduced surface, which saves fuel.

For the bath

In a separate direction I. Kuznetsov allocated bath stoves. There are three varieties: BIC, BIC BK and BIC PC. The abbreviation BIC is appropriate, and additional symbols indicate that the structure is equipped with a fireplace.

For different layouts, choose models that differ in the location of the furnace and fireplace - in the steam room, relaxation room or in the dressing room.

DIY construction

To undertake construction on their own is appropriate only to a person with the skills of a bricklayer. In furnace construction, there are many subtleties that become clear only after many years of work.The main points worth learning in order to monitor the work of hired craftsmen and independently choose materials.

Model selection

Construction begins with a model choice. Even at the stage of manufacturing the project determine:

- appointment;

- the necessary heat transfer power;

- configuration

- masonry materials and their quantity.

The summary table on the site indicates: geometric dimensions and heat transfer of each side. After the transition to the "drawings for free" section, in order, up to a brick, the amount of materials is calculated. For the drawings of some furnaces you will have to pay a small amount - for the purchase you will need to register on the site.

Materials & Supplies

All consumables are selected and bought in advance, since after the start of construction you can quickly not find, for example, doors or bolts of the required size.

For the Kuznetsov furnace, you will need:

- three types of bricks - corpulent red with a brand not lower than M-150, fireclay heat resistant, better than SB-8 and finishing for the outer layer of masonry;

- sand-cement mixture for furnaces;

- cast products according to the drawing - doors for the combustion chamber and ash chamber, grate, gate valves and views, doors for treatment channels;

- wire for dressing the rows from the calculation of laying around the perimeter of every two rows;

- corners of overlapping for a fire chamber;

- reinforcing mesh for pouring the foundation;

- asbestos cord for thermal insulation of cast iron fittings.

For work, you will need a trowel or trowel, containers for mixing solutions, level, alignment, tape measure and plumb.

At the first stage of construction, a foundation is arranged, the length and width of which corresponds to the dimensions of the furnace. To do this, make a recess in the soil, pour and compact 10-15 cm of sand. Prepared formwork is poured with heavy concrete.

The upper edge of the flooded foundation is made 13-15 cm below the floor level, then the recess is laid with two layers of refractory brick. They are needed so that the heat does not go through the floor into the ground.

The time to set the foundation with full strength is 28 days, but laying can be started in 17–20 days if the construction is not planned to be completed very quickly.

At the next stages, the “body” of the furnace is erected, strictly following the instructions, observing the order and adjusting the horizontal and vertical levels.

The passage of the chimney through the floors is provided with thermal insulation, excluding the heating of building materials.

Immediately after the construction is completed, a test furnace of low intensity is made. At this time, all substances that give an unpleasant odor burn out, and the walls warm up and dry evenly.

Is it worth it to build on your own

The amount of teaching material on the inventor’s website and serial drawings allow you to build a bell-type furnace for a bathhouse or a house yourself. In this case, be sure to observe the sequence of work. Real estate owners who are unsure of their building skills turn to specialized firms.

The device of powerful dome structures is best entrusted to professionals. This ultimately saves time and money.

In any case, it is worth practicing by erecting a small-sized Kuznetsov heating stove, for example, in a utility room or a shed for pets. Only after this can we begin the construction of a furnace in a residential building. A correctly selected and manufactured construction will last for many years without breakdowns.