A Russian bath is distinguished by a combination of moist (over 60%) air with a high temperature. The constant increase in humid environment with the help of finely divided steam involves the use of special equipment. Domestic Hephaestus stoves can operate in the Russian steam and Finnish saunas, which ensures the comfort of water procedures.

Technical characteristics of Hephaestus furnaces

For the manufacture of furnace equipment, the manufacturer uses cast iron. The metal is characterized by high heat capacity, rapid heat transfer from the inner to the outer layer. Gefest brand produces furnaces that:

- have walls 10-50 mm thick;

- accumulate heat even when the flame goes out;

- suitable for heating rooms from 45 to 120 cubic meters;

- are made with cast iron shutter or heat-resistant glass door;

- maintain the temperature of the stone from 500 to 700 degrees;

- equipped with secondary gas afterburning mode and a flame arrester;

- have an efficiency of 87%;

- work from solid fuel - firewood or briquettes;

- equipped with auxiliary elements to increase the distance from the portal to the furnace.

Units are available in three versions - a heater with a grid, with coil lining and a brick lining.

Advantages and disadvantages

The range of Hephaestus bath stoves is designed so that the room is heated as quickly as possible. The equipment also has a number of advantages:

- Durability. For the manufacture of stoves cast iron SCH20-25 CHX10 is used, which is characterized by high strength. Additionally, the product is reinforced with vertical stiffeners to withstand heavy loads. Connection of elements by welding and bolts is not used.

- Economic mode of operation. The heater is made in the form of a trapezoid, equipped with a flame-extinguishing device and a secondary gas burning system. Due to this, the movement of flue gases is carried out along the walls. Convection ribs increase the surface that emits heat.

- Long operation in the smoldering mode. Due to the afterburning mode of pearlite gas and the gate after heating the steam room, the stove can be left on decay. At the end of the combustion process, a comfortable temperature is maintained for several hours.

- Preparation of finely divided light vapor. The design of the furnace equipment allows for a long time to maintain a temperature of 500-700 degrees, at which useful light steam is obtained.

- Environmental friendliness. Cast iron has a unique crystal lattice; therefore, it does not corrode upon access of moisture. The material at the time of heating does not emit substances harmful to human health.

- Adjusting the distance from the portal to the back wall. Using a transition extension cord, you can increase this distance by 10 cm.

- Reliability. Doors are equipped with German panoramic heat-resistant glass. The ash pan is made of stainless steel 1 mm thick. The starting part of the chimney is made of cast iron.

- Keeping heat in the steam room. The large specific gravity of cast iron and the design of the furnace allows you to maintain the desired temperature for 5 hours.

The furnace is distinguished by its only drawback - high cost. It is easily compensated by increased wear resistance and positive performance.

The range of Hephaestus furnaces

Hephaestus bath stoves are presented with options for small paired and overall models. The manufacturer offers several modifications of the equipment.

Cast iron stoves

Reliable cast iron stove for a sauna or bath Hephaestus is equipped with a forged mesh under the stones, suitable for brick cladding. Some models come complete with natural cladding. Products look harmonious due to the elongation of the starting pipe or lining, decorated with casting, enamel or patina.

Depending on the type of cladding, you can choose equipment of the Optima series with an open box part, President and Russian steam room, which have a closed type of box and a special mesh under the stone.

Cast iron stoves differ:

- durability and resistance to corrosion;

- heat resistance due to chromium impurities;

- high efficiency - from 85%;

- special design - three cutouts in the shape of a trapezoid increase the heated area;

- the presence of a flame extinguisher, contributing to the movement of flue gases in the direction of the side walls;

- thick walls (1-6 cm) with vertical stiffeners, S-shaped convection ribs for swirling hot air flows;

- stainless steel steam box (Russian steam and President series).

Cast iron models are characterized by fuel economy and long cooling.

Bath equipment

The furnace, which is installed in the bathhouse, must maintain a comfortable microclimate, therefore the Hephaestus brand manufactures heat-resistant, corrosion-resistant and acid-resistant units. They do not have joints and seams, therefore they withstand vertical loads. Panoramic sashes are made using the “clear glass” technology. The wood type of equipment is equipped with a flame arrester, ceramic sealing cord. The following series are intended for Russian baths:

- Classic. Alloy cast iron units with 2 furnaces and a gas afterburning system for quick room heating. The furnace tunnel can be adjusted in length. The stove is operated in steam mode, equipped with heat-resistant Robax glass and an ash-drawer made of stainless steel.

- 3K. They are made with reinforced heater and one furnace recess. To increase the contact zone of the heater and fire, a heat-removing seam is used. The stones heat up to 500 degrees, creating a shallow steam. Heat transfer of the combustion temperature of firewood to the air is carried out using convection ribs.

- Hurricane. The furnace unit is equipped with a high forged mesh, cast-iron duct, flip door, mounting spacer and a starting pipe 50 cm long made of cast iron. The mesh is easily replaced with stone cladding without disassembling the furnace. Kamenka has the form of a trapezoid, it is used in the mode of long burning. The firebox is adjustable.

- Thunder. Premium models heat up 2 times faster than other modifications, are equipped with a cast-iron box and a cast-iron starting pipe. The side walls with a thickness of 14 mm are characterized by high heat storage capacity. The furnace is equipped with internal and external convection fins.

- Storm. Suitable for small and medium steam rooms, consist of two chambers. Radiator tabs are recessed into the firebox. To increase the heating zone, there are cast-iron spikes for bath stones or dense charges on the outside.

The equipment looks like fireplaces; it can be used for 30 years.

Models with a closed heater

A closed type of heater is provided by a cast-iron lining box, a spacer for mounting the flap and the flap itself. Hephaestus stove holds a large number of stones, produces soft steam of fine dispersion. Oven for stones - overall, from 50x62x75 cm, depending on the model.

The gas-fired combustion chamber consists of 2 chambers separated by a flame arrester. The furnace tunnel is led into the next room using an elongated portal. All parts are solid. The closed heater is represented by modifications:

- Hurricane - characterized by the classic design of the heater. For stones or cast-iron cones, small side niches are intended.

- Hurricane-3K - has a modernized heater with a base 40 cm thick. To obtain more heat, cast iron spikes are located on the furnace side.

The walls of the units with a thickness of 12-60 mm do not burn out, do not corrode.

Other devices Hephaestus

In addition to heating equipment, the manufacturer produces a series of Mini. It is distinguished by compactness, ease of use. The line includes several modifications.

- The gas oven is equipped with a temperature sensor, burners for any diameter of the dishes. The gas furnace with mechanical or touch control from Hephaestus is characterized by uniform heating of the walls and surface, spaciousness, and the presence of an integrated controller.

- Hob for cooking - the stove is painted in various colors, has an attractive design. Burners can be spiral or induction, enamel or glass ceramics are used to cover the hob. It is operated in the mode of upper and lower heat, grill, convection.

- Combined models - combine the gas type of the hob and the electric type of oven. The tile is suitable for gasified houses, differs in simplicity of management and extensive functionality of the electric oven.

- Cooktop

- Combined cooker

- Mini model for a summer residence

Mini line is suitable for houses, cottages, apartments, country cottages.

The specifics of the installation of Hephaestus furnaces

The manufacturer's instructions note that the stove is a device with a surface that can heat up to 350 degrees. Its installation should be carried out in compliance with the distance:

- from combustible materials - 50 cm vertically, 120 cm from above;

- fire-resistant space - 10 cm on both sides of the sash and 40 cm in front of it;

- from a brick wall - 5 cm.

Uninsulated nozzles of the furnace and chimney are removed from combustible objects 100 cm horizontally and 120 cm vertically. The distance for the modules is 10 cm from flammable objects and 40 cm from the ceiling.

The room where the stove is installed must meet the fire safety requirements prescribed in SNiP 2.08.02-89.

Step by step installation

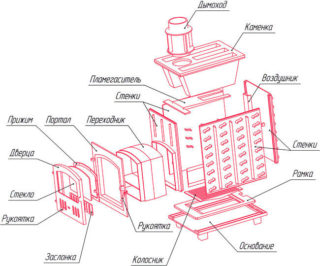

Installation work is carried out after removal of the factory packaging and inspection of the product in the following order:

- Placement of the base on a flat surface with a grease groove sealant.

- Coating the grooves of the walls on the front and rear sides with sealant.

- Installing the unit walls in the grooves, the frames - on the protruding tides of the side walls, the grate - in a special opening.

- Mounting the arrester in the groove of the front side. The walls of the stove are always held.

- Mounting the heater on the edge of the walls.

- Installation of an ash pan and first heating on the street (at least 60 minutes).

- The conclusion of the chimney. For a combustible roof, a spark catcher is organized. When outputting from the ceiling, a cut is performed 7 cm more than the overlap.

Bookmark stones are washed with a brush to remove harmful compounds.

Choosing a furnace for the size of the room

The manufacturer’s assortment contains five series, suitable for rooms of various sizes:

- PB-00M and 000M are intended for steam rooms on 80-120 m3;

- PB-01 - 4 units for rooms up to 45 m3;

- PB-02 - 10 models for steam rooms up to 35 m3 are presented;

- PB-03 - 10 products for rooms up to 25 m3;

- PB-04 - stoves for a bath (5 models) on 15 m3.

All devices are suitable for baths and steam rooms, work on wood or special briquettes.

Hephaestus furnaces are distinguished by worthy technical characteristics, ease of use in rooms of various quadrature. At a high cost, the furnace equipment pays off for the first season, it is safe and able to create healthy steam.