Innovative approaches in the construction of various types of hangars allow you to adapt buildings to any climate conditions. Structures are characterized by high strength and reliability. Additional processing provides resistance to corrosion.

Why do we need hangar insulation

The hangar is a functional structure used in various fields of activity. The choice of model depends on consumer needs. When warming buildings, the type of installation technology is taken into account.

High-quality insulation of the hangar makes it possible to expand the scope of use of the building. It can be operated as a room for a sports complex or production workshop.

Thermal insulation provides sound insulation, reduces heat loss. Multilayer insulation provides the building with strength and rigidity, serves as protection against rust and condensate.

Types and features of hangars

Hangars are erected on a frame basis and without it. Each model has its own positive and negative characteristics. Installation technology, operation and maintenance of various structures has much in common.

Wireframe

Models are buildings based on a metal frame. The hangar is installed on the foundation and covered with cladding. The frame must be assembled and disassembled. The structural elements are fastened by means of bolts. The functionality and economy of the building depend on the shape.

The frame is based on channels, I-beams and pipes, as well as other metal components. The design is processed by a primer of any color. Metal hangars are cold and warm. The walls of cold models are not subject to insulation.

Frameless

Frameless models are built directly at the construction site using special mobile devices. Construction involves the profiling and corrugation of coiled steel with giving it the desired radius. The arched element is connected into blocks using a clasp machine. Then they are lifted by a crane and installed on a finished foundation. Elements of the building are fastened by spot welding and bolts.

Advantages and disadvantages

The strength is distinguished by designs based on a metal frame. The service life with proper use and prevention is twice as long as that of frameless models.

The technical advantage is due to:

- the presence of a strong foundation;

- installation of strong supporting elements;

- high level of stability of the hangar.

The disadvantages of the construction include the duration of the construction of the foundation. Usually, given good weather, filling the base can take up to two weeks. With constant rain it will take a month. The assembly of the frame is carried out after the concrete has completely solidified.

The main advantages of a frameless construction include water tightness and tightness of seam fittings, which reduces operating costs.

By cons include:

- reduction of the useful area of the hangar due to giving the building an arched shape;

- limitation of the overall dimensions of the building;

- low rate of height.

Frameless models are installed at once, as they cannot be disassembled. In the event of a breakdown, the building cannot be repaired. It is possible to replace only part of the arches with the edge. Elements in the middle are not restored. Design fasteners also have disadvantages.

Equipment for the manufacture of frameless models should be on the construction site, although some companies offer a service for the installation of the finished structure.

Hangar insulation options

An important element of the hangar is its insulation. To ensure the optimum temperature resort to the use of various materials.

Sheathing with corrugated board and galvanizing is carried out externally and internally. Internal insulation reduces the construction area, but such insulation is highly efficient.

The outdoor installation of the panels has the main function and serves as protection against heating and hypothermia. This increases the duration of operation.

As heat insulators, sandwich panels, ecowool, polyurethane foam (PUF), foamed polyethylene or foamed foil coated with foil, and mineral wool are usually used.

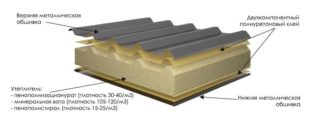

Sandwich panels

The material contains three layers. Two of them are made of galvanized metal sheet. The third serves as insulation. Often in its role is mineral wool. The market has wall and roofing elements that differ in color.

Insulation through sandwich panels is a profitable solution for the construction of a hangar with straight walls. Panels act not only as a heat insulator. They serve as a fence, protecting the building. Elements differ in esthetic appeal.

Wall insulation with sandwich panels is characterized by low thermal conductivity and a high level of strength. The panels are lightweight, which makes it possible to fill the foundation with a shallow depth.

Mineral wool

Mineral wool is used as a separate material. She is going in layers. It has a density of 130-140 kg / m. The insulation does not change the quality and shape when the temperature changes and can be used when it is too high. Mineral wool is resistant to chemicals and weather conditions, protects the metal frame from rust.

The material is used for any model of construction. It can also be used in the construction of a frameless structure.

The main disadvantage is the lack of resistance to moisture. To eliminate water absorption, mineral wool is coated with a special membrane film. The same rules are followed when conducting work inside the building.

The material is affordable, quick installation and easy to use. The price of mineral wool depends on the thickness, density and brand of the substance.

Ecowool

Ecowool is a cellulose insulation. It is not subject to decay, is not flammable and does not become moldy. It is an environmentally friendly material.

Ecowool can be used to insulate hangars in which food products are stored. Installation can be carried out both outside and inside. It is carried out wet or dry. In the latter method, cellulosic fibers are blown between two surfaces. In the wet method, the fibers are wetted with water, to which glue is added. The product is applied by spraying. A dense coating without seams and affordable cost makes this type of insulation a priority.

Polyurethane foam

Foam is applied to the surface of the hangar using a special apparatus in which the components of the insulation material are mixed. The finished mixture enters the sprayer under high pressure. On the surface, polyurethane reacts chemically with air, and as a result it turns into foam. The capture of air molecules contributes to an increase in volume of 80-100 times. The material solves a lot of problems thanks to the application method and technical characteristics.This method of insulation is often used by developers, since installation is quick and easy.

Polyurethane foam is an ideal way to warm an arch hangar. It has a high level of adhesion to metal, applicable to any form of construction.

The material provides a flat surface without cracks and gaps. It does not require long and expensive preparation for application. Warming PPU hangars allows you to control the thickness of the insulation, which saves money.

Polyurethane foam has excellent adhesion to the surface of the walls, even with existing bumps, bends or the presence of complex structural forms. This explains the use of the substance for arch frameless structures and polygonal structures.

The service life of polyurethane foam insulation is 30 years. In the absence of bad weather conditions, the duration of use increases to 50 years. The hardened substance does not give additional load on the foundation. The cost of PPU depends on the thickness of the layer and dimensions of the hangar.

Foamed polyethylene or foil foamed

The basis is polyethylene foam coated with a reflective foil. Thermal insulation is an innovative approach to thermal insulation. The thickness of penofol is not more than 1 cm, the foil layer is 20 microns. For cold regions, 40 mm thick material is available.

The disadvantages of the material include:

- low rate of rigidity;

- conductivity of electricity;

- high level of adhesion.

The main advantage is reflection. Due to this property, the heat does not stay in the room, as it happens during the installation of other heaters. The method provides coolness in summer and warm in winter. Also, the advantage is the low weight, which provides ease of installation and transportation. Penofol does not create a large load on the structure.

Durability and positive performance have made penofol popular. The material does not break, which makes it possible to warm the hangars a second time.