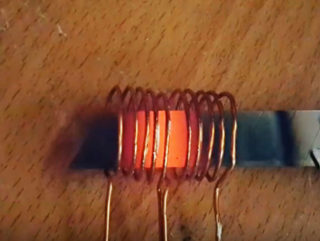

The inductive heater functions due to the interaction of the eddy currents generated by the electromagnetic field of the inductor with a metal surface. There are several schemes for making an induction heater with your own hands. The most affordable of them are structures made of polypropylene pipe and a welding inverter.

The principle of operation of the induction heater

When an alternating electric current flows in a spiral of a choke, an electromagnetic field is formed around it. When placed in the middle of the coil of the core of a metal with magnetic properties, its temperature rises. This induction heating is a phenomenon that occurs under the influence of eddy currents. It is observed only when the throttle is powered by an alternating electric current having a sufficient frequency of changes in sign and direction. When a direct current is supplied to the inductive part, the core temperature does not change.

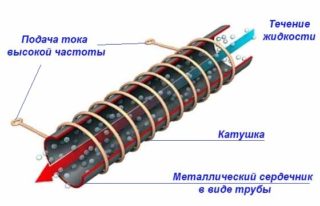

The functioning of an inductor for heating workpieces is based on this principle. The main component of the unit in most cases is a spiral configuration of metal. In cooking stoves, a flattened element located at a small distance from the hob is used in this role. In the boiler, the role of the inductor is played by a steel tube filled with coolant (its function is liquid).

Important components of the unit under consideration are an alternator and a heating element. The first is used to obtain power of a sufficiently high frequency from a typical apartment electrical network of 50 Hz. The second is a metal structure capable of absorbing heat when in the field. The generator directs an electric current reduced to the required parameters to the inductor (spiral element). In this case, a stream of charged particles, creating a field, goes through the coil. A metal placed in its zone of action is heated by the action of Fouquet currents without direct contact with the inductor. To heat water in such an aggregate, it is necessary to have its contact with the heating element. The simplest example of such a design would be a metal pipe through which water flows. In the process, the fluid cools the walls, which extends the life of the structure.

Advantages and disadvantages of the device

Induction heating can provide a number of benefits that are not able to give the use of electrode devices. Since the heating of the liquid is carried out by a metal element that does not take part in electrochemical reactions, the durability of the device depends only on the coil. The duration of its operation is determined by the duration of the device. Some inductors remain operational for more than 10 years. Associated with this is the compatibility of the unit with different types of heat transfer fluids. In addition to plain water, machine oils and non-freezing compounds are suitable for this role.

The inside of the unit during use is not covered by accumulations of scale. Due to constant contact with the liquid, the likelihood of overheating of parts is reduced, which also helps to extend the service life. Convection in the device usually reaches a sufficient level so that it is not required to install a circulation pump.There is no need for noise insulation measures - the device works quite quietly.

However, the induction heater also has weaknesses:

- The device requires electrical energy to function. In a room where electricity is not supplied or there is no way to provide access to it, the boiler will not be able to work. In places with regular network interruptions, it will not work effectively.

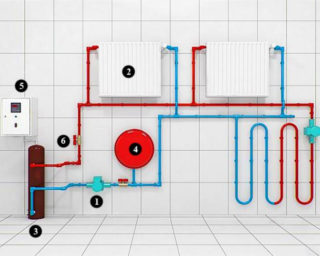

- If the temperature rises excessively, the heat-transferring liquid transforms into a gaseous state. This provokes a strong increase in pressure in the structure, as a result of which pipe rupture can occur. To prevent this from happening, it will be necessary to equip the installation with means for controlling pressure and temperature. This can be a manometer, a temperature sensor, a device for emergency shutdown when the parameters go beyond the specified range.

The need for additional accessories can contribute to a serious increase in the cost of equipment for a home-made induction heater.

The device is considered almost completely silent, but in practice this is not always the case. This applies to models of industrial production and installations designed at home.

Homemade device options

There are several ways to make a heater at home. The most affordable option is to make a device from a kitchen electric stove and a polypropylene pipe. Difficult in execution, but powerful enough is the inverter unit.

Pipe heating element

This development involves the dismantling of a spiral inductor installed in an electric stove, and the placement of a new design in its place. For its manufacture, a polypropylene tube with a length of 0.5 m and a diameter of 4 cm, a magnetic element, 5 textolite rods, bends for connecting to a heating network will be required. You will also need to purchase a coil of conductor with a cross-sectional area of 2 mm² coated with glass-isol (such a cable is often used in welding transformer devices) and metal washcloths.

The sequence of steps in the manufacture of the apparatus:

- A magnet is placed in the tube and filled with washcloths (the use of chopped wire is permissible instead).

- Mount bends with threads.

- Rods are glued along the body, onto which a wire coated with glass is wound.

- Disassemble the hob and remove from it the factory inductor, made in the form of a flat spiral. In its place, a prepared design is installed.

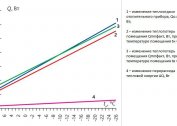

The heater in this unit are metal washcloths placed in an alternating field of the coil. When the panel is launched in maximum mode with parallel transmission of water, it will turn out to be heated by 15-20 ° C. Considering that the tiles used for construction usually have a power of not more than 2000 W, the resulting unit is suitable for heating residential premises up to 25 m².

The efficiency of the device can be increased by connecting it to the welding machine, but such work is fraught with a number of difficulties. Firstly, the apparatus will need to be disassembled and look for places that have not yet been straightened on the diagram. This is due to the fact that a direct current is created in it, and an alternating current is required for the functioning of the heater. Secondly, it will be necessary to use thicker wiring (for example, copper with a diameter of 1.5 mm, coated with enamel composition) and calculate the required number of turns. Finally, it will be necessary to introduce a cooling mechanism into the installation.

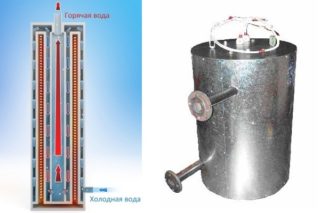

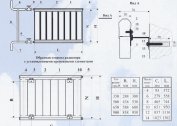

Induction boiler assembly

This solution does not involve disassembling the tiles. Instead, the master will need to weld the boiler tank according to its dimensions.A profile tube is made of steel with a thickness of 2 mm and a hole dimension of 2 by 4 cm. From it, it will be necessary to make blank elements along the width of the panel. Pipes are welded along the length, combining smaller sides. Up and down to the end parts need to be hermetically welded tires made of iron. Holes are made in them and pipes equipped with threads are installed. You also need to weld a couple of corners forming a shelf for the oven.

You need to paint the device with a heat-resistant enamel composition. After drying and fixing, the boiler is mounted on the wall and cut into the heating system. The hob is placed in a nest with corners and connected to the mains. Then you need to fill the installation with coolant, bleed the air masses and start heating the inductor element.

Homemade heater is not enough power to heat large living spaces. On a frosty winter, he will be able to heat two small rooms. During the transitional seasons, when the air temperature in the street is about zero, the unit will be able to serve large areas - up to 40 m2.

From welding inverter

If you intend to use a welding machine, it must be borne in mind that connecting the inductor to its clamps directly is strictly prohibited. Violation of this requirement is fraught with the loss of operability of all elements of the installation. In order to combine an inductive heater with a welding machine, the latter will have to carry out a number of complex manipulations that require the experience of a master and a detailed understanding of the unit's structure. The primary winding must be connected after the high-frequency signal converter of the inverter mechanism instead of its built-in inductive choke. In addition, it is necessary to solder the condensation unit and dismantle the diode bridge.

How to make a powerful induction heater

The considered devices have a power consumption in the region of 2.5 kW. To make a device with a higher indicator (4 kW), the master needs serious knowledge in the field of radio electronics. An inexperienced radio amateur is unsafe to undertake this work.

One option may be a design of a power supply with two pairs of windings, a transformer, a driver and a control board. The frequency value at which the unit operates is inferior to the resonant one. Two coils serve to supply drivers, one for the control board, and one is power. It feeds the starting relay, fan and cooler pump.

Safety tips

Installations of this type are widely used not only for space heating, but also for melting. The main problem associated with home-made induction devices is the lack of components that provide temperature and pressure control and explosion protection. Therefore, when operating such units, care must be taken.

Before starting up the boiler, check the filling of the cavity with coolant. A body made of polymers will start to melt without regular liquid cooling. This entails deformation changes and a complete failure of the installation. Also, the danger of a falling out of the heated metal from the melting body. In such an incident, it will be necessary to replace a number of plant components.

The device is connected to electricity through a separate wire, which is led from the shield. Contacts must be covered with insulating material. If a welding apparatus is involved in the design, its inverter must be grounded. The wire used for this operation should be 4-6 mm across.To prevent excessive heating of the installation in the absence of water, it is advisable to install an overpressure valve in the inlet.

Conclusions and recommendations

Taking on an independent manufacture of the device is reasonable if the farm already has an induction panel. The cost of its acquisition is quite high and comparable with the price of an electrode heater. The power of some of these models reaches 10 kW, while only a craftsman with the proper level of competence can make an installation at home above 2.5 kW at home (at least you need to be able to assemble a frequency converter circuit). Also, before installation, it is necessary to make sure that there are no cracks or holes through which liquid from the heat source can leak out: such an incident can cause a fire.

The induction heater of simple design, designed to service a small area of the room, is easy to make without special preparation. More powerful and efficient options, for example, with a welding machine or two circuit boards, require a collector of competencies in the field of radio electronics. The structural features of these plants necessitate the acquisition of additional controls to ensure safety.