Adjusting the heating system is an important process that allows you to evenly distribute hot water along the circuit. For this, special equipment is used, which includes a balancing valve. They are placed in private cottages, apartment buildings with an extensive heating network, when tying the boiler with a thermal battery. The stores offer a wide range of regulatory products with the same operating principle and different designs. The home master should know what a balancing valve is, how to mount and configure it for efficient operation.

Purpose of the balancing valve

The balancing valve is a device designed to increase the maximum heat transfer of all heating devices in the heating system and the ability to adjust them individually. This is a relatively new product that has come to replace obsolete washers and a method for calculating pipe diameters for flow control. It greatly facilitates the work, making the adjustment more accurate, and the flow of hot water in the heating circuit more economical.

The coolant flowing in the pipelines is distributed throughout all sections of the heating circuit. The latest flow control method involves the use of a balancing valve. It is a valve, by rotation of which the amount of coolant in a particular element of the system will change.

The valve should include the following details:

- Durable brass body. Inside are threaded pipes for connecting pipes. It also has a saddle in the form of a mirror channel.

- Adjusting spindle. This is a device that has a working part in the form of a cone and is screwed into the saddle. Thanks to him, the coolant flow is blocked.

- O-rings They are made of various durable materials (metal, rubber).

- Plastic or metal cap.

The valve also has two special fittings that determine the pressure and allow you to connect a capillary tube. In the event of a differential pressure, these devices calculate the flow rate.

Unlike a regular tap

The balancing valve adjusts the permeability level. Sometimes they put a regular tap instead. Such a system is less accurate and rougher. The choice of method depends on the result that the residents of the house want to get. Spherical cranes with the switch can be put. Then the lever is put in different directions. This is also an inconvenient and inaccurate method.

The balancing valve has special inputs and outputs at which liquid flow is measured. Thanks to this property, you can make adjustments at any time.

Principle of operation

The device operates by changing the flow area when the valve is turned. When the knob, which is used to adjust the passing amount of coolant, is scrolled, the torque is transmitted to the nut and spindle. The last element rises higher when unscrewed. In the lower position, it blocks the flow of water and prevents it from entering the pipes. In intermediate states, the amount of energy entering the element of the heating circuit will change.

The adjustment will change the resistance of the valve to the flow of coolant.Water follows the path of least resistance, as a result, distant heating devices heat worse. Thanks to the use of a balancing valve, an artificial resistance is created in the path of the coolant, which accelerates its transfer to distant circuits.

Such work should be carried out with a complete tightness of the heating circuit. For this, different types of o-rings are used, made from durable materials - fluoroplastic, dense rubber, metal.

Types of valves

Devices can be classified by control method. Manual and automatic balancing valves are distinguished.

The positive qualities of the manual type include:

- High quality work under stable pressure.

- Ease of customization.

- Possibility of installation in houses and apartments with a small amount of heating batteries.

- The ability to carry out repairs without shutting down the entire system. It is enough to close the valve in the area where repairs will be carried out.

The optimal conditions for using a manual valve are when the number of radiators in the heating circuit in the room does not exceed 5 units. In this case, the mechanism will work with the greatest efficiency.

With a large number of radiators, it is not possible to manually adjust all devices. In case of overlapping the thermostat in the first radiator, the flow rate increases in subsequent ones. This leads to uneven heating of each product. The way out is the installation of automatic valves. Such mechanisms are placed on heating branches, which are equipped with a large number of radiators.

The principle of operation is slightly different from a mechanical valve. The valve is installed in the maximum water flow position. In the event of a decrease in energy consumption by a thermostat, pressure increases on one of the batteries. At this moment, a capillary tube starts to operate, which includes an automatic balancing valve for heating. He, in turn, analyzes the pressure drop and promptly corrects fluid flow. The process is so fast that other thermostats do not have time to overlap. As a result, the user gets a constantly balanced system.

The advantages of automatic valves include:

- The presence of a capillary tube, thanks to which the adjusting mechanism is triggered instantly.

- Stability of pressure indicators. It is not affected even by fluctuations caused by the operation of thermostats.

There are no strict criteria for choosing a device. The equipment is not difficult to manufacture, so even inexpensive valves will perform their task efficiently.

Setting the radiator network balance

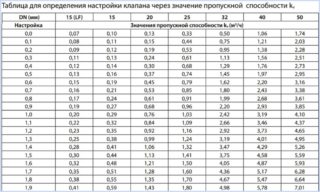

The quality of space heating depends on the correctness of the system regulation. Each valve is accompanied by a user manual that describes how to calculate the number of turns of the handle. According to the instructions, you can set the settings so that there is an optimal flow rate of the coolant and savings on heating.

According to the instructions, the valve spins to a certain level. There are two ways to adjust. Choosing the right one depends only on the convenience for the master and the availability of the tool.

Method 1

This method is offered by experienced professionals. They mentally divide the valve speed by the number of radiators that are placed around the entire perimeter of the room. By such a calculation, it is possible to accurately determine the desired adjustment step. The basic principle is to shut off all taps in the reverse order.

An example is a system consisting of 5 batteries with manual valves. The spindle is adjustable 4.5 turns.To determine the step, you need to divide 4.5 by 5 and get 0.9 turn.

This is a simple and reliable way, which can be used by anyone who adjusts the system in their home, without the use of additional devices.

Method 2

This is also an effective method of adjustment, but its implementation will require a special contact type thermometer. This technique is faster and allows you to change the settings of each radiator, taking into account its individual characteristics.

Process algorithm:

- Open all valves. It is necessary to allow the system to warm to 80 ° C.

- Measure the temperature of each radiator with a thermometer.

- Eliminate the resulting difference between the first and middle taps by overlapping them. Usually the first one is cranked up by 1.5 turns, and the middle ones by 2.5.

Further, within 20 minutes it is forbidden to carry out any adjustment work. When the system adapts to new conditions, it is necessary to measure again each element of the heating system. The main task, as in the previous case, is to eliminate the temperature difference with which all radiators are heated.

The most famous brands involved in the creation and supply of valves is Danish Danfoss. It is a leader in the production of high quality valves. German Herz, Russian ADL, Caleffi and others are also popular. Graduation is carried out by Russian and foreign companies. Products of various formats are offered, with various pressures, temperatures and other indicators. The mechanism of action for all products is the same.