In order for the residential building to be constructed to be warm and cozy, it is necessary to warm it well by choosing high-quality heat-insulating materials. Modern heaters are represented by a wide variety of models that differ in price and technical characteristics. Comparing products from different manufacturers, including Rocklight insulation, will help you make the right choice of the right material.

Rocklight Product Features

Mineral wool from a well-known manufacturer is an insulating non-combustible plate, characterized by low thermal conductivity. They are made from natural minerals (basalt rocks) and are intended for warming and sound insulation of buildings under construction. Properties characterizing this material include ease of installation and attractive operating parameters.

The qualities of Rocklight mineral wool insulation are appreciated by most experts and ordinary users. They attract many private developers with their properties. Of particular practical interest to the latter are the technical characteristics of Rocklight insulation.

Technical specifications and dimensions

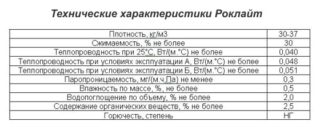

Minvata Rocklight is distinguished by excellent operational performance, the consideration of which evaluates the following characteristics:

- thermal conductivity of the insulation component of 0.036 W / meter;

- allowable percentage of compression (no more than 30);

- structural density of 30-37 kg / m3;

- hygroscopicity, estimated as moisture absorption by the volume of the plate (not more than 2%);

- flammability (degree of NG).

The listed indicators correspond to the requirements and standards for modern thermal insulation, operated in various climatic conditions. By themselves, they are not a record, but in certain conditions, due to their combinations, good results can be achieved. The density of the material (compression ratio) during the installation of insulation inside buildings and in the attics of buildings is of decisive importance. Thanks to this characteristic, it is possible to calculate the value of the deformation load that wool can withstand without losing its original shape.

Insulation blanks from Techno Rocklight are available in packages. The dimensions of the sheets are 1200 × 600 × 50 mm or 1200 × 600 × 100 mm. These dimensions are among the most popular, since mineral wool mats of this size are easily located in the frame structures.

If one layer is not enough for effective thermal insulation, it is allowed to combine the blanks of the Technonikol Rocklight insulation or arrange them in several levels.

Advantages and disadvantages

Insulation Technonikol Rocklight in comparison with other materials of this class has the following advantages:

Insulation Technonikol Rocklight in comparison with other materials of this class has the following advantages:

- low thermal conductivity;

- unique ability to save heat with which only environmentally friendly cotton wool can compete;

- resistance to fire and the spread of fire;

- ability to maintain its shape for a long time;

- low hygroscopicity taking into account the use of a special insulating layer;

- good absorption of sound waves, thanks to which the Rocklight minplita can be used for sound insulation.

The material is resistant to rodents, insects and harmful microorganisms.

If we compare Rocklight with Rockwool, it can be noted that when creating the first, not only basalt, but also additives in the form of extruded polystyrene foam are used.Compared with other samples, this insulation material is lighter, which reduces transportation costs and simplifies installation. However, it is quite durable, so it is used in places where a less rigid insulation is not allowed to be mounted.

The material has one drawback - high cost.

Thermal insulation boards from Rockwool deservedly belong to the category of better products, which at the same time have a very reasonable price. But the Rocklight products comparable to it have many positive properties, which attracts the attention of users.

Features of installation of Rocklight insulation

Rocklight thermal insulation is used when it is necessary to insulate the following structural elements:

- flooring located on the first floors of buildings;

- attic floors in private and urban homes;

- pitched and ordinary flat roofs;

- if necessary, insulation of building facades for siding, etc.

After familiarizing yourself with the properties of basalt thermal insulation samples, you will need to master the techniques of independent insulation of roofs and facades.

Warming of facades of houses

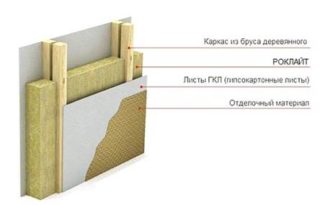

Before proceeding with the insulation of the facade of the house with mineral Rockwool, you need to mount a frame of metal profiles or wooden beams. The width of the cells should correspond to the size of the insulation boards (50, 100 or 150 mm). Further actions on the arrangement of wall surfaces look like this:

- A waterproofing material (plastic film) is laid on top of the frame structure, which protects the insulation from moisture. It is mounted with an overlap of at least 15 cm, after which the joints between the individual pieces of film are glued with construction tape.

- TechnoNIKOL thermal insulation boards are placed between the bars. They are reliably fixed in the guides due to the fact that the distance between the latter is made 1-1.5 cm less than the width of the plates themselves.

- The thermal insulation on top is closed by a vapor barrier membrane. In this case, special attention is paid to ensure that the film with its smooth side is turned towards the insulation.

At the final stage of installation work, wooden slats with a width of about 20-30 mm are packed on top of the insulating “pie”. A gap of this size is recommended according to the instructions, so that moisture accumulating there can erode from the surface of the waterproofing film. The decorative cladding of the facade is mounted on the bars of the previously prepared counter-battens. It can be vinyl siding, PVC panels, OSB boards.

Insulation of the pitched roof

The installation procedure for the insulation of pitched roofs:

- From the inside of the rafters, a wooden crate is stuffed with a small step. The distances between the rails are chosen not very large so that the insulation boards laid on them do not sag under their own weight.

- During installation, it is necessary to ensure that in the joint areas the mats are firmly pressed against one another. If necessary, the insulation is laid in two layers with the overlapping of the second level with the first.

- A layer of wind and waterproofing film is mounted on top. It is attached to the rafters with a slight sag, which guarantees the condensation to drain.

The upper side of the waterproofing film reliably protects the insulation from moisture, and the lower side provides free outflow from it of the vapor vapor accumulated in the house. Pieces of plastic film used as steam insulation are stacked with an overlap of about 15 cm.

It will be necessary to equip the ventilation gap, for which another crate of wooden blocks is packed on top of the finished structure. This element of the insulation cake is necessary so that condensate accumulating on the surface of the film can easily erode.

Application in various fields of construction

Rocklight insulation mats, thanks to the previously considered advantages, are actively used in private construction. The scope of this material is very extensive:

- stone wool is widely used for insulation of inclined, vertical and horizontal surfaces;

- plates are selected if necessary to protect structural corner elements;

- the material is often used for thermal insulation of floor slabs, as well as pitched roofs.

Rocklight mineral wool slabs are widely used in the arrangement of foundation foundations and basements. This high-quality heat insulator is in great demand for warming light attics and frame buildings.