In heating circuits, a check valve for heating is installed. The element is used in the system when connecting a second boiler, a branch of a warm floor, a water heater or an automatic water make-up device. Type of shutoff valves is used to prevent reverse energy flow and protect against water hammer.

Purpose of the check valve for heating

Counter flow of coolant occurs under various circumstances: when the circulation pump stops or errors in the system design. The reverse movement of water is observed in the case of uneven cooling of sections of the heating main, when a pipe or joint breaks. Sometimes the cause is uneven pressure in the pipeline sections.

A non-return valve is provided in the system to prevent damage to the boiler and other elements of the line due to the flow of water in the opposite direction. The mechanism allows energy to pass in one direction and blocks movement in the other. The device is used in communal heat supply and piping, and is installed in the heating circuits of a private house and multi-storey sector.

Some types are designed to work in certain circumstances, for example, when entering the boiler room, shockless and shock type valves are used. With a small pipe diameter (up to 400 mm), water hammer does not harm the system. In large highways, dampers are placed against sudden shocks. Such return devices cut into horizontal parts of pipelines.

Varieties of check valves

There are valves installed using couplings, flanges. Some require special fittings, welding. Clutch mechanisms are threaded, easily connected, such a unit is used on disk valves. Couplings are used to install fittings in an apartment or in your own house.

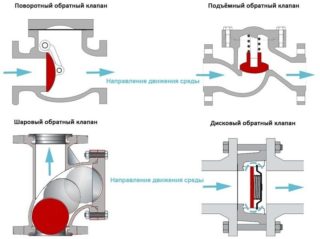

Check valves are distinguished by their design, operating conditions and purpose.

There are shutter devices:

- petal;

- dish type;

- ball varieties.

- Ball

- Plate

- Petal

Flanged structures have additional parts with mounting holes and are attached to the trunk elements using bolts and nuts. The connection is durable and is used in large diameter pipelines. Flanged devices are placed between the edges of the pipes, they weigh a little and have small dimensions. Welded valves are placed when the circuit is set with polypropylene pipes.

Petal

A thin steel plate serves as a shutter and is mounted on a hinged structure, which ensures a movable position.

The petal non-return valve for heating is available in two types:

- rotary or single-leaf;

- bivalve.

In the first variety, there is one plate that rotates around the center line. The flap rises when the coolant moves in a given direction. The passage hole is closed by the descending part on the spring during reverse flow. Bicuspid devices are equipped with two locking plates, fixed on the central axis and located in the passage of the hole.

Petal species have advantages:

- some valves do not have springs; these types are used in natural gravity systems (gravity);

- devices are inexpensive.

The negative side is that the bicuspid type interferes with the fluid flow, therefore it is used only in high-pressure lines.

Dish-type products

The shutter is made in the form of a disk of metal or plastic. An element blocks the flow of liquid if the energy carrier changes direction. The disk is mounted on a spring, which is in a compressed position with direct movement. A change in direction leads to a straightening of the part and a change in the location of the locking disc. The design has a sealant for a tight fit of the shutter, such a part completely eliminates leakage.

Advantages of butterfly valves for home heating circuits:

- small dimensions and light weight allow the use of mechanisms on the contours of small diameter;

- the device does not require periodic technical inspection and repair;

- The device is not expensive.

The disadvantage is the inability to repair the poppet valve, so replacement is required. The mechanism creates resistance to flow and is not used in schemes with geothermal pumps. Salt sediment is deposited on the disk, the device stops working.

A standard clapper valve for heating systems when locked creates a water hammer in the system. Developed disc valves with a smooth closing mechanism, which have a higher cost.

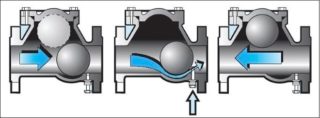

Ball valves

The shutter mechanism is made in the form of a ball of aluminum or other metals. The element is coated with rubber to extend its life. The ball element rises when the water flow moves in the right direction and is located at the top of the valve. The energy carrier does not enter the opposite side, because the element lowers and closes the hole.

Advantages of ball valves:

- the design works reliably, because the structure does not provide for rubbing and moving parts;

- at the top of the mechanism there is a cover for inspection or repair;

- the device does not create water hammer in the system when moving the ball.

The disadvantages include the large diameter, because of which ball valves are used in high-diameter mains, and connection to household heating networks is not always appropriate.

Advantages and disadvantages

The non-return valve has the disadvantages and advantages common to all types of devices. No hot stream will flow into the riser if cold liquid flows there. This extends the performance of system elements that are designed for a specific temperature. Devices are mounted simply and do not create noise during the passage of fluid. Check valves solve the problem only in a particular area, for other circuits additional control devices are installed.

Some mechanisms allow the occurrence of water hammer during the passage of the flow of the working unit, but this feature of the valve only harms a system with a large diameter. The valves become contaminated by water flow if the energy carrier in the system is free of propylene glycol or other additives. In this case, the disc or plate may jam in an open or closed position.

Installation and setup rules

The valve must be installed in the direction of the main current, for this there is an arrow on the body. The joints are sealed with paronite, but the gasket is placed so that the inner diameter of the passage device does not decrease. The condition is important to prevent water hammer in the pipeline network.

The device is placed so that other elements of the line do not affect its operation. The pipe section with the valve can be supported by a metal frame to prevent vibrations or other influences.A mesh for coarse cleaning of solid impurities is placed in front of the passage mechanism.

Connection schemes options

The connection versions of devices depend on the type of system and on the type of valve. Devices are placed on each circuit in a closed circuit, but circulation pumps are always installed. In a single-circuit pipeline, the non-return valve can be cut out.

In multi-circuit systems, a shut-off valve for the reverse current is necessarily set, because when the pump is turned off, the energy carrier moves along a small branch. The mechanism is mounted in the trunk with an indirect heating water heater, especially if there is no separate pump.

Shutoff valves are installed in highways with a bypass, when the system is rebuilt from gravitational current to forced. In the make-up piping section, the valve is placed to prevent liquid from being thrown back into the water supply.