The comfort of staying in the room, the mood and health of residents depends on the quality of heating in the house and apartment. If you put a heating mat under the tile, you can achieve perfect heating of rooms where warm air will be distributed evenly throughout their volume. Installation can be done by yourself, well saving on the services of specialists. To achieve the best result, you should familiarize yourself with the varieties and features of the products on sale, study the technology of their installation.

Varieties of heating mats

Electric mats for underfloor heating for tiles are a complex multi-layer structure consisting of several functional elements. The basis of the product is a fiberglass mesh with high strength, flexibility and resistance to high temperatures.

A cable with a diameter of 3-4.5 mm is welded into the grid, having the following device:

- a metal core that heats up when electricity passes through it;

- polymer insulation;

- copper braid screen;

- external insulation.

The cable is evenly distributed along the base in the form of a wave with an amplitude of 50 cm and a distance between the wires of 8-12 cm. Temperature sensors and temperature controllers are supplied or purchased in addition to the products.

According to the electrical circuit, heating mats are divided into the following types:

- Single core. They consist of one continuous conductor, which closes in a circuit. Products emit a large amount of electromagnetic radiation and are designed to equip non-residential rooms (corridor, loggia, bathroom). When laying mats, it is necessary to attach the desired position for ease of connection to the network.

- Two-core. They consist of two conductors, one of which is heating, and the other wired. The presence of two cores simplifies the installation of mats and reduces the electromagnetic background.

After laying the products, they are connected to the household network 220 through the connection sleeve. Reliable insulation of wires and joints allows you not to worry about the safety of property owners.

Advantages and disadvantages

Electric mats laid in a warm floor, like any similar products, have their pros and cons. The combination of tiles and heaters gives a much better effect than linoleum and laminate.

Among the advantages of products include:

- Environmental Safety. Exposed parts of the equipment do not emit harmful substances into the air. Two-core structures produce an acceptable level of electromagnetic radiation.

- High performance. The optimal distribution of the cable over the grid contributes to uniform heating of the surface. No cold spots.

- Ease of installation. Mats just roll out like a regular rug. The surface of the product is embossed. An adhesive solution adheres well to it, on which the floor covering is laid.

- The heating mat is thin enough not to produce a significant increase in floor level.

- Energy efficiency. In the underfloor heating system, the heating mat transfers heat to the tile in a direct way. Losses are practically absent.

- Simplicity of calculations. There is no need to consider how much cable or pipes are required. it is enough to divide the area of the room by the area of one mat.

- Maintaining a comfortable temperature for a certain time of the year.Automatic controls allow you to set the desired value with an accuracy of 1 degree.

Matt floor heaters also have their drawbacks. These include high primary costs for the purchase of material and a large consumption of electricity at medium and maximum mode. In addition, repairing the product is impossible in principle. When the mat fails, it is necessary to open the tile coating and replace the faulty fragment.

Features of choosing a suitable option

To choose the right floor heating system, you need to focus on a number of criteria of the product itself and the features of its operation.

To choose the right floor heating system, you need to focus on a number of criteria of the product itself and the features of its operation.

When buying, you should consider the following points:

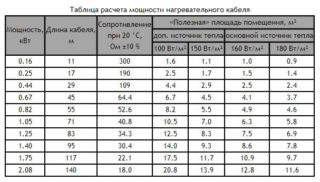

- Power. For various models, it varies between 100-200 W / m². The choice depends on whether the floor structure will be used as primary or secondary heating.

- Warranty period. Given the peculiarity of the placement of heating elements, you should purchase high-quality products from trusted manufacturers.

- Coverage and room configuration. You should take mats in such a configuration that they evenly cover the surface of the screed, without overlapping.

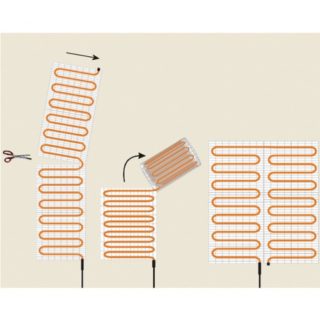

It must be borne in mind that you cannot cut mats by cable, you can only shorten the wires for connecting to the network.

Stacking and connection

The correct approach to installation involves the use of high-quality materials and proper placement of elements. Do not stack heaters under cabinet furniture and household appliances. Lack of air circulation leads to overheating and burnout of the cable.

To work, you will need:

- roulette, level;

- a grinder or tile cutter, a powerful drill or punch with a mixer;

- mallet;

- notched trowel, rubber trowel;

- adhesive for tiles; grout for joints;

- plastic crosses;

- sponge;

- container for mixing the solution.

Given the peculiarity of the work, it must be done in soft shoes, a respirator, goggles and gloves.

Laying of floor mats is carried out in the following sequence:

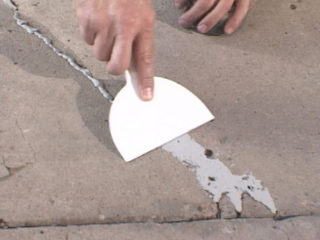

- Checking the condition of the screed. In the presence of cracks, holes, chips, they are sealed and leveled with cement mortar.

- Priming surface treatment. This will strengthen the surface of the material and improve its adhesion.

- Arrangement of thermal insulation. To do this, take a dense and rigid polystyrene foam, finished on the front side with foil.

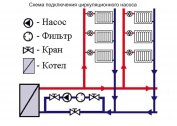

- A styling scheme is drawn up. Strobes are made for laying the cable and a hole for installing the thermostat. Thermostats should be at a distance of 10 cm from the wall and 15 cm from the radiators.

- Layout of mats, carrying out their cutting. You need to do this on a grid without affecting the wire.

- Bonding products to the base. If the net is from below, the cable is recessed to its entire thickness into the solution. When the wires are on top, gluing is done pointwise. All further actions are carried out after the glue has completely dried.

- Connecting wires to the thermostat and the network, checking the design. This is best done before installing the finish, as then something will be impossible to fix.

- Kneading heat-resistant glue and coating it with the surface of the heating elements, so as not to damage them during tile laying, when the product will be under strong pressure and there is a risk of falling heavy, sharp objects.

- Drawing up a tile laying scheme. If necessary, you can lay it out in patterns and mark it. After that, the drawing is transferred to the base.

- Surface treatment by deep penetration impregnation. It is better to make at least two applications to ensure quality preparation.

- Kneading adhesive.It is applied with a notched trowel to the back of the tile, which is then pressed to the floor in accordance with the markings. Pottery is laid in rows, starting from the far wall. Horizontal and alignment are controlled by level and plastic crosses.

- Grouting. Previously, they are cleaned and treated with a primer. The solution is pressed into the openings so that it fills them completely. Excess grout is removed and reused.

- After drying, the tile is washed with a soft cloth.

It is possible to include the structure into the network only after the adhesive has completely hardened.

Manufacturers of heating mats

On sale are domestic and foreign products.

The best proven heating mats of such brands:

- Equation

- Thermal Suite;

- DEVI;

- Nexans

- Ensto;

- Hestedt;

- Profi Therm;

- Extherm;

- Fenix;

- Woks;

- RATEY

- Veria

Purchases should be made at proven retail outlets, without fail checking the availability of a quality certificate.