Heat losses seriously increase heating costs. Part of the wall behind the radiator is the place with maximum heat loss, so it is recommended to install a heat reflector there. Reflecting surfaces are used to direct heat fluxes into the room. They are applicable for complex structures with corners and bends. The heat-reflecting screens behind the radiator are made of various materials, often with a foil surface. With their help, it is possible to increase the efficiency of the heating system by an average of 20%, which leads to an increase in the temperature of the heated room by 2-3 ° C.

Operating principle

There are several basic ways of transferring heat from one coating to another:

- thermal conductivity, which is the ability to conduct heat;

- convection, during which heat is transferred through the air;

- radiation associated with the release of a thermal wave by heated bodies.

These processes are associated with heat loss, which can reach several tens of percent. In order to maximize the effect of thermal insulation, they need to be reduced. This can be done using heat-reflecting screens having a foil surface. This type of insulation works according to all the principles of heat transfer and inhibits heat loss processes.

Screen Materials

The reflective screen is made of the following materials:

- Folgoplast SP. This is an analogue of insulation, which is a self-adhesive film with a layer of foil. It is made from the made foam polyethylene. The material attaches well to different surfaces. It has high thermal insulation properties, does not absorb moisture, does not rot and is environmentally friendly. Suitable for installation in residential premises.

- Folgoplast SPMP. This is aluminum foil, which is coated with a layer of metallized dacron film. It protects the material from mechanical damage and oxidation.

- Folgoplast P. Material in which there is no adhesive base on aluminum foil.

- Folgoplast PMP. A layer of foamed polyethylene, which on one side has a metallized polyester film.

For installation behind the radiator, foam can be used in various modifications.

The use of reflectors

Heat-reflecting screens can be used for different purposes. The main field of application is the internal insulation of premises of various purposes, mainly residential. Thanks to the reflective surface, all the heat from the radiators goes into the room. There are two ways to do this. The first option is to create two air gaps between the wall and the material, as well as between the insulation and the cladding. For this, TIM with double foil is used. Also, a gap can be made between the outer wall and the insulation. In this case, a material that has one foil surface is used. The foil should always be directed inside the room.

Thermal insulation screen can be used for the roof. It creates thermal and steam insulation, protecting the roof from moisture.

Reflective surfaces have found their application in pipe insulation and ventilation. In this case, insulation with foil is used on both sides. For pipes with a diameter of less than 159 mm, an air gap is not necessary, in other cases it is mandatory. A fastening is created from rings of foil film at a distance of 300-400 mm from each other, wrapped with insulation on top.It is also possible to lay wooden blocks 10 × 10 mm or 20 × 20 mm along the pipes, and insulation on top. All joints are sealed with aluminum tape.

Mounting the screen behind a heating radiator is one of the most popular applications. Prices for energy sources are constantly growing, so it is important to keep as much heat as possible in the house. In the space between the battery and the wall, the greatest heat losses are noted, so self-installation of the screen in this place will significantly reduce costs.

Product design

The reflective screen for the heating battery is made from materials whose main property is low thermal conductivity, not exceeding 0.05 W / m * C. All screens have a layer of insulation. The sheet consists of foil and a layer that retains heat.

Foamed polyethylene is often used as insulation. It has good thermal insulation properties, technical characteristics and low cost. Basal cardboard is mainly used for thermal protection of furnaces.

Front reflectors for heating batteries in baths are a good substitute for masonry. They allow you to increase the temperature and produce heating of adjacent rooms. The thickness of the steel sheet should be at least 0.8 m. An organosilicon paint is used as a coating.

When installing screens under a wooden coating on the wall in the steam room, the security of the room increases. The role of the screen is aluminum foil, the joints between the sheets of which are sealed with special metal tape. It is used if the temperature of the external walls of the furnace is not higher than 400 ° C.

The main advantages of heat-reflecting screens:

- Wide scope. They are suitable for installation at home, in shopping centers, saunas, industries and other residential and non-residential premises.

- Achieving energy savings by maintaining heat in the room.

- Ease of installation. No need to call the wizard to install the screen for the battery.

- No specialized care and complicated maintenance required.

- Light weight and flexible. No special conditions are required for transportation.

- A wide selection of materials from any price range.

- Low thermal conductivity.

- Easy to cut into pieces of the required size with a conventional construction knife.

- Moisture protection.

- The possibility of insulation of internal surfaces.

- Ensuring reflection of heat waves with an efficiency of 97%.

You can purchase a screen in specialized stores.

Mounting Features

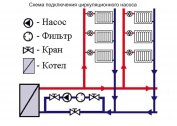

To maintain a comfortable temperature in the house, a heat reflector is placed behind the radiator and pipes. It saves about 10% of the heat. When choosing the material for installation, please note that the dimensions of the sheets must be larger than the heating battery. The type of radiator connection is also taken into account.

The heat-reflecting screen can be mounted on a construction stapler. You can install yourself on the instructions from the manufacturer.

Basic tips from screen mounting experts for the battery:

- It’s best not to buy matt metallized material. Polished foil is more suitable as a heat reflector.

- For installation behind a radiator, a heat-protective film with a one-sided coating is sufficient. Double-sided is used for other purposes. Its cost is higher, but its efficiency will not change.

- It is necessary to leave a fence of 1-2 cm on both sides of the insulator. Due to the distance, the optimal thermal resistance of the reflector will be obtained, the screen will be able to effectively reflect all the heat inside the room.

Rules for installing the reflector behind the radiator:

- It is necessary to ensure the tightness of the screen.To do this, all joints are sealed with metallic tape.

- Efficiency is achieved only when using metallized aluminum foil. In the case of the use of material with a metal coating or produced by a thermal method, the desired effect will not be achieved. This is due to the small thickness of the metal reflective layer.

- If it is impossible to put a professional reflective screen, you can make an independent reflector. To do this, take plywood and cover it with foil or use galvanized sheet.

- The effectiveness of the screen depends on the distance between the reflector and the battery.

- The insulation thickness must be at least 5 mm.

- The reflecting surface should be directed towards the radiator.

Installation is done using a stapler, liquid nails or other adhesive, which is recommended by the manufacturer.

Procedure:

- Measurements of wall sections and radiator.

- Purchase of materials. To the resulting size you need to add stock.

- Checking the distance between the heater and the installation location of the film. In the absence of free space, it is necessary to adjust the battery suspension.

- Removing the radiator.

- Create marks on the wall where the mounting brackets will be installed. Dismantling the fasteners on which the battery hangs.

- Inspection of the integrity of the masonry wall surface. If necessary, cracks, crevices and other defects should be repaired. Alignment of the walls.

- Gluing the screen.

- Installation of suspensions and radiator in place.

Instead of glue or liquid nails, staples can be used. It is important that they pass through the material and not cause it to rupture.