For the correct completion of any type of work with heating, it is necessary to pressure test it. This applies to almost all heating systems. However, due to an incomplete understanding of the importance of the procedure, this rule is not always respected. In order to avoid emergency situations, it is necessary to understand what constitutes pressure testing of the heating system: presses, pumps, pressure and other important parameters and components.

Purpose of pressure testing of heating

During operation of the heat supply, a natural change in the size of the components occurs: the diameter of the pipes, radiator pipes, boilers and safety groups. What is heating pressure testing and how can it identify these problems?

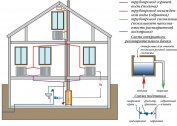

After completing installation work of the new heating or reconstruction of the old, there is a likelihood of microcracks at the joints. The apparatus for crimping the heating system will allow you to identify these problems before starting the heat supply. The essence of his work is to create increased pressure on a specific section of the system or the entire network. Visual inspection or monitoring of the pressure state will help to identify problem areas in the heating.

Pressure testing of heating with air or with a liquid is necessary in the following cases:

- At the end of installation or repair work;

- Before the start of the heating season;

- After flushing the heating system;

- When replacing individual heat supply elements.

To perform this procedure, pumps are used to pressure test the heating. They can be hydraulic or pneumatic type. It is recommended to draw up a planned schedule according to which pressure testing of the heating system in the apartment or house will be done. But first you should choose the equipment and deal with the process technology in more detail.

Often, the planned crimping of heating pipes is combined with their flushing. This can be done using the same pumps.

Types of pressure testing of heat supply

There are several ways to crimp a heating system with your own hands. They differ not only in the equipment used, but also in the order of testing. The choice is largely determined by the complexity of the heat supply scheme.

First of all, you should find out the norms of crimping the heating system. They directly depend on the nominal pressure indicator in the system, its length and technical operating conditions of specific heat supply devices. Radiator manufacturers indicate nominal values for crimping. To connect pipes and valves, these data can be taken from a preliminary calculation of the heat supply parameters.

In the work, you can use a hand pump for pressure testing of heating or its analogue with an electric drive. The choice will not affect the quality of work, but only affect the complexity of its implementation.

A professional press for crimping heating systems can be rented. This will save money on the purchase of an expensive installation.

Hydraulic pressure testing of heat supply

The most popular and effective way of crimping a heating system in an apartment or house is the hydraulic method. For its implementation, it is necessary to fill the system (or its section) with liquid and increase the pressure to the required level using the pump.

Do-it-yourself pressure testing of the heating system by the hydraulic method is carried out only after analyzing the pressure indicators in the system.To do this, you need to know the normal value of this indicator in the system. In stand-alone circuits, it is 2.5-3 atm. For centralized pressure indicator can reach 4-5 atm.

Before connecting the apparatus for crimping the heating system, it is recommended to check the condition of the assembly units and installed components. If this is not a new system, it is necessary to flush it. To do this, you can use pumps to pressure test the heating.

The essence of a hydraulic heating test is as follows:

- After filling the system with water, the pressure indicator is measured and primary control is performed - no leaks;

- Then, using an automatic or manual pump to pressure test the heating, the pressure increases. Its value should be 20-30% more than the maximum. The exposure time should not be more than 20-30 minutes;

- Visual inspection of the condition of pipelines and radiators;

- Decrease in pressure to normal and stabilization within 5-6 hours.

During this procedure, the coolant does not heat up. High water temperatures can adversely affect the pressure test of heating systems.

The most important task is to determine the pressure of the heating system. It should not be critical for heat supply elements. Therefore, before performing this procedure, you should familiarize yourself with the technical characteristics of pipes, radiators, batteries, and the boiler.

Even a slight decrease in pressure in the system indicates a leak. You can determine its location using a sheet of thin paper, attaching it to the mounting units.

Pneumatic pressure testing of heat supply

In rare cases, air is used to create the necessary overpressure for crimping the heating system. The difference lies in the greater complexity of the work and the difficulties in determining the place of future leaks.

In this case, the same standards of pressure testing of heating systems apply. However, for a more efficient verification of heat supply, it will be necessary to apply a method for monitoring its condition, which differs from the hydraulic method.

The difference lies in the following nuances:

- Pre-purge the system to remove debris, scale and other elements;

- Connecting the apparatus for crimping the heat supply system. After that, all valves are interrupted - Mayevsky's taps, drain valves and air vents;

- A pressure exceeding normal by 20-25% is pumped into the system;

- Within a certain period of time, the pressure gauge is monitored. If there is a decrease in pressure, the system is not completely tight;

- To determine the place of future leakage, the pneumatic pump for pressure testing the heat supply is alternately connected to various parts of the system. Therefore, a defect can be found.

After fixing the leak, the equipment is turned on again and the pressure gauge is checked again. This method is not recommended for autonomous heating of a private house or apartments, since it is difficult to identify potentially damaged sections of the network with its help. Most often, pressure testing of heating with air is performed in long-distance networks so as not to waste heat carrier.

Before pressure testing of heating pipes, it is necessary to visually check their integrity, to check the condition of welded and screw joints.

Pumps for pressure testing of heating

Knowing what pressure testing of the heating system is and how to conduct it, you should understand the types of equipment used. To perform this work, special installations are used, which differ in configuration, design and technical parameters.

Manual models of pumps for pressure testing of heating have a piston system for creating pressure. Electric - power plants for pumping fluid.Almost all of them are self-priming. For a small amount of work, it is recommended to use a mechanical press for crimping heat supply systems. If the volume of coolant in the heating is large enough, then it is more advisable to choose the electric type of pumps. They differ structurally in the following ways:

- Membrane

- Piston;

- Lamellar-rotor.

Most often, for hydraulic pressure testing of a heating system in an apartment, piston systems are used because of their affordable cost and reliability. If the injection of air into the system is planned, it is recommended to stop the choice on another type of equipment. In this case, diaphragm pumps are the best option. With their help, you can quickly and professionally make a pressure test of the heating system with your own hands.

In addition to the design features, the operational limitations of the equipment should be taken into account:

- Coolant type. In some models, it is not recommended to use antifreeze for crimping heat supply pipes;

- Possibility of flushing. To do this, a water filtration system should be included in the pump package;

- Specifications - the maximum allowable pressure, performance, pressure.

Currently, there are several models designed to create the desired pressure indicator of the pressure test of the heat supply system.

| Model | Cost, rub. |

| Valve, 10 l. mechanical | 4880 |

| POE-60, electric | 23700 |

| NOR-63, mechanical | 8250 |

The purchase of a pump for crimping is impractical. It is best to rent it. On average, its daily cost is from 5% to 10% of the cost of the product.

If the pump design does not have a filtration system, it must be installed on the supply pipe. Otherwise, it is likely that expensive equipment will fail at the time of operation.

How is the heating test

Before self-testing the heating system, a number of preparatory work should be carried out. First of all, check the condition of all elements and try to identify possible breakdowns and malfunctions even before the procedure begins.

The required norms of crimping the heat supply system, which directly depend on its actual parameters, are preliminarily determined. If necessary, pipes and radiators are cleaned. To do this, remove the old coolant. It is recommended to use universal types of pumps that are designed both for crimping and for flushing.

Then the following stages of work are performed:

- Filling the system with coolant. For pressure testing, it is best to use ordinary water, since it has an optimal density indicator.

- Connecting the press and increasing the pressure in the line to the required level.

- Reconciliation on the gauge indicator.

If the pressure in the system has not changed within 30-40 minutes, it means that all the elements are in good condition and you can do a trial run of heat supply. A constant decrease in pressure indicates leakage in pipes or radiators. If it is not possible to visually determine it, pressure testing should be done at each of the heating sections.

In central heating, this procedure should be performed by representatives of the Management Company. When submitting an application, the reason for the need to pressure test the heat supply in the apartment is indicated. Most often, this is the replacement of radiators and pipes. In addition, these measures are recommended to be done at least once every 2-3 years.

The heating test certificate is only drawn up when the house is put into operation or upon completion of preventive and repair work in the central heating supply. It is not needed when crimping autonomous heating or pipes and radiators in an apartment.

You can learn about the features of performing pressure testing of heating from the video material: