The dwelling made of wood is the warmest and most comfortable for human habitation. To ensure comfort, the ceiling is insulated in a wooden house. This allows you to save heat from heating devices and serves as an obstacle to the penetration of cold air from the outside. The operation can be performed independently. It is important to study the process technology, strictly follow it when performing work, choose the right insulation.

Choice of insulation

Choosing a material for warming a wooden ceiling, you should decide how the material will be laid - from the outside or from the inside. External thermal insulation involves the placement of insulation in the attic. In this case, you can use bulk materials - sawdust or expanded clay, as well as mineral wool, glass wool. For filing the ceiling from the inside, roll sheets or foam sheets are suitable.

Sawdust

The cheapest and most affordable insulation is sawdust. They are pre-mixed with cement and diluted with water in a ratio of 1:10. The resulting mixture is coated on an insulated surface. To get high-quality insulation, sawdust must meet the following requirements:

- good drying;

- lack of mold and foreign smell;

- age not less than a year;

- Medium sized pieces.

Sawdust is used to insulate the ceiling from above. Before applying the mixture to the surface, it is necessary to lay a waterproofing layer of roofing material or plastic film.

Mineral wool

For thermal insulation of the ceiling, mineral (stone) wool is used. This is a loose soft material, consists of thin fibers, air cavities remain between them, which ensure the preservation of heat. Minvata can not be sealed during installation, so as not to break the air gap.

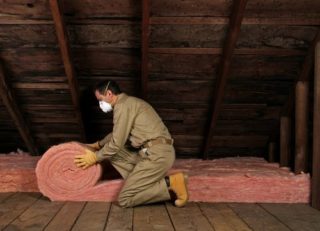

For insulation of the attic ceiling, it is convenient to use a heater in mats. It is placed between the roof rafters and fastened to the crate with nails with wide hats. The thickness of the insulation layer is preliminarily determined using a heat engineering calculation. In addition to thermal insulation, the insulation provides sound insulation.

Minvata is characterized by a long service life, but requires a thick layer to protect it from the cold. The disadvantages include its high hygroscopicity, which requires a reliable waterproofing layer.

Roll insulation

As rolled insulation use mineral or glass wool. They have a low density, providing them with softness and the ability to roll up. Stone wool is a non-combustible material - does not support combustion, does not cause smoke.

Glass wool - insulation, which consists of glass threads, confused in a chaotic manner. Requires protection of the body and respiratory system when working with it. It is a lightweight, elastic fiber, fire resistant. High quality materials have German manufacturers.

Ecowool is made from cellulose, has a beautiful light gray color, and is used for finishing the ceiling.

Styrofoam

To properly insulate the ceiling in a wooden house, you should pay attention to the foam. This porous synthetic material is light weight, it retains heat well, waterproof. Available in the form of rectangular plates of various sizes and thicknesses. They are easy to install, they can have a decorative coating, which excludes additional decoration of the ceiling. It is used for thermal insulation indoors and outdoors.

Clay insulation

The advantages of natural natural material include its environmental friendliness, ductility, low thermal conductivity, ease of use. Clay is mixed with sawdust, the resulting mass is applied to the ceiling surface covered with a water-repellent film. In the process of clay drying, cracks appear, which immediately cover up. A layer of 15 cm is sufficient to maintain heat.

Independent warming

How the ceiling will be insulated in the house depends on its design features, the material of the insulation and the wishes of the owner.

Ceiling insulation

The process is similar to floor insulation. The insulation is placed on the attic floor between the lags. For example, consider laying mineral wool. Work execution order:

- They put a vapor barrier film between the lags and on them, fasten with a construction stapler.

- Mineral wool mats are tightly placed between the lags, having previously cut them into plates of the desired size.

- Lay out a layer of waterproofing from sheets of roofing material. A gap of 2-3 cm is left between the roofing material and the insulation surface. The waterproofing is nailed to the logs.

- If the attic is exploitable, they make the floor covering from boards, chipboard or plywood sheets.

Expanded clay is used for thermal insulation. It has positive qualities: it does not burn, it is environmentally friendly, it is not damaged by rodents and insects, it is not covered by mold. It is poured with a layer of 20-25 cm. A thicker layer has a greater load on the overlap, a smaller one will not provide sufficient thermal protection.

Insulation of the ceiling with polystyrene is carried out according to the same methodology as mineral wool. Of the advantages - ease of installation, does not absorb moisture, lack of dust and dirt during installation. Light weight does not increase the load on the ceiling. You can’t step on polystyrene; boards or plywood are laid on the lags.

Insulation of the ceiling from the inside

If necessary, insulate the ceiling from the inside of the room, it must be borne in mind that its height will decrease by the thickness of the insulating layer. Warm air, in contact with the cold ceiling, forms condensation. The first is to apply a vapor barrier layer to prevent moisture from entering wooden surfaces. After laying the insulation, it is also isolated from steam.

Materials for vapor barrier must be non-combustible, not emit harmful substances, protect the ceiling from wet fumes. Isolation from steam provides a comfortable climate in the rooms and protects building structures.

For vapor barrier use a plastic film, foil polyethylene, polypropylene. The coating is made continuous, individual sheets of film are stacked with an overlap of 150 mm.

The order of the work on the device of thermal insulation of the ceiling:

- Vapor barrier made of roofing material or plastic film. Can be fixed with glue.

- Mount the mounting rail with screws.

- Polyfoam is installed between the rails. When using rolled material, it is rolled on the surface and glued.

- Lay a second layer of vapor barrier.

- The thermal insulation cake is masked with PVC, gypsum plasterboard or lining panels.

- Drywall is painted with acrylic paints.

Mineral wool is not recommended for internal insulation. To obtain the desired effect, it is necessary to lay its thick layer, which significantly reduces the height of the room.

Preparatory work

To obtain a high-quality thermal insulation coating, the base is carefully prepared. The first step is to remove the remains of construction debris, dirt, washed from dust and dry the ceiling. The cracks between the boards are covered with sealant.If they are small, use putty on wood.

Wood is susceptible to harmful insects, mold and fungus. To protect the wood use impregnation, flame retardant primers. Coat thoroughly without leaving spaces.

Possible mistakes

When insulating a wooden house on their own, people who do not have experience in construction make a number of mistakes that can significantly affect the initial result. One of the most important is insufficient protection of the structure from moisture, lack of vapor barrier and waterproofing.

The second mistake is the high load on the floor structure caused by the use of materials having a large weight. This causes deformation and sagging of the ceiling, the threat of its collapse. Strengthening the ceiling is costly and inconvenient when living in such a room.

A serious mistake is a violation of the density of joints between the elements of the insulation, which contributes to the formation of cold bridges. To avoid this, the seams are coated with sealant. You can leave a gap between the plates of 5 mm, then close it with mounting foam, which ensures a guaranteed connection of individual sheets.

An ideal option to ensure a comfortable room temperature is to insulate the ceiling and walls during the construction of a house. If there is a need to do this during the operation of the premises, work is performed in the summer in good weather.