Do-it-yourself installation of heating has always required a large amount of knowledge and practical experience in performing this type of work. However, steel pipelines and cast-iron radiators were replaced by other system components. When using polymer pipelines, the installation of heat supply will be much simpler. In order to make heating from polypropylene pipes with your own hands, you need to know the installation rules, diagrams, and it is advisable to get acquainted with the reviews.

Advantages and disadvantages of polypropylene pipes in heating

The choice of this type of material is due to many factors. First of all, this is a relatively simple installation of heating from polypropylene pipes with your own hands. But their technical and operational properties should also be considered.

Properly designed and implemented heating from polypropylene pipes in a private house has many advantages. These include a low rate of heat loss. Due to the use of polymers in the manufacture, their thermal conductivity is one of the lowest. This is a determining factor why they prefer to make heating from polypropylene pipes with their own hands.

In addition to these advantages, the heat supply from polymer highways has the following qualities:

- Non-corrosive. Over time, polypropylene reinforced heating pipes practically do not change the wall thickness. This increases the durability and reliability of the heat supply;

- They are not destroyed by ultraviolet radiation.. This phenomenon can be observed with metal-plastic analogues. But if the manufacturing technology and material composition are observed, German polypropylene pipes for heating can last up to 30 years;

- Smooth inner surface reduces hydraulic resistance in the system. As a result, this affects the thermal distribution and inertia of the heating operation;

- Simple installation technology. You will need a minimum set of tools and accessories. But before that you need to learn how to choose polypropylene pipes for heating;

- Affordable cost. For autonomous heating systems installed independently, this is the determining factor of choice.

However, even the highest quality polypropylene pipes for heating Rehau have several disadvantages. They are characteristic of all products made of this material and are determined by the initial properties. A large coefficient of thermal expansion affects the installation technology and the selection of components. To eliminate it, installation of compensation loops is necessary. It is also possible to destroy the material when oils, paints, and other household and construction compounds get on its surface.

For a long service life, the heating scheme from polypropylene pipes should provide for a low-temperature mode of operation. Exposure to high temperatures (from + 95 ° С and more) leads to the gradual destruction of the polymer surface.

The choice of polypropylene pipes

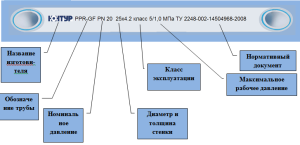

The selection of a specific model begins with an examination of what labeling polypropylene pipes for heating means. It will determine the suitability of this material for installation in a heat supply system with specific technical indicators.

For heating, it is necessary to use pipes with a reinforcing layer.It can be made of aluminum foil or fiberglass. The latter is preferred, since Kalde polypropylene heating pipes with fiberglass are easier to install and have a longer service life. In heating, the use of pipes made from a PP-R copolymer is recommended. It is designed for high temperatures, which is a prerequisite for the maintenance-free operation of the heating system.

All these data, including the sizes of polypropylene pipes for heating, can be found in the marking. In addition to these characteristics, it is recommended to pay attention to the following parameters:

- Pressure indicator. It can be learned from the letter PN. The following numbers indicate the maximum allowable pressure. For example, the PN15 model is designed for operation in circuits with a maximum pressure of up to 15 atm;

- Diameter and wall thickness. All polypropylene pipes for heating Valtec and other manufacturers are characterized by an outer diameter. Therefore, to calculate the internal indicator, two wall thicknesses should be taken away;

- Operation class. In the labeling of polypropylene pipes for heating, this indicator indicates the maximum allowable temperature effect. For autonomous systems, it is recommended to install models with a fifth (up to + 90 ° C) or fourth (up to + 70 ° C) class of operation.

Additionally, manufacturers make color coding. So, many models of polypropylene pipes for heating Rehau have blue and red stripes on the surface. This means that they can be used for cold water supply and heating.

The quality of polypropylene products can be determined by their end. If even a minimal detachment from the reinforcing layer is observed on it, this indicates a marriage.

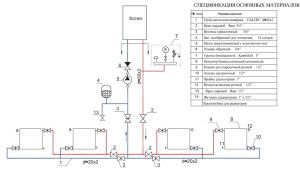

Heating schemes made of polypropylene pipes

Most often, the installation of a heating system with polypropylene pipes is selected for heat supply with forced circulation. Highways of small diameter are used for this - from 16 to 24 mm. Although installation options are possible in schemes with the gravitational movement of hot water.

The main problem in installing heating from polypropylene pipes with a large diameter with your own hands is the tool. Standard household semi-professional soldering irons are designed for connecting pipes up to 32 mm. In gravitational heat supply, the installation of pipelines with a diameter of about 40 mm is recommended. To do this, you will need special equipment, the purchase or rental of which will be inappropriate.

But despite this, reviews of polypropylene pipes for heating indicate good performance in the following schemes:

- Closed with forced circulation;

- Open with forced circulation;

- Two-pipe and one-pipe;

- Collector.

For each of them, an individual technology for installing a heating system with polypropylene pipes has been developed. It is important to pre-calculate the optimal dimensions of the pipelines, their configuration and wiring diagram. This can be done using software or manually using standard formulas and tabular data.

The term of a maintenance-free heating service from polypropylene pipes in a private house largely depends on the operating conditions. For the above circuits, the use of low temperature operation is recommended. This will ensure a minimum load on the surface of the lines.

Also, during the installation of heating from polypropylene pipes with your own hands, you must follow all installation rules. Otherwise, there will be a chance of hidden defects that will cause a breakdown or failure of the heat supply.

For a medium-sized private house, the two-pipe heating scheme of polypropylene pipes with a lower wiring is most often used. It is easy to install and has good heat distribution performance.

Installation of heating from polypropylene pipes

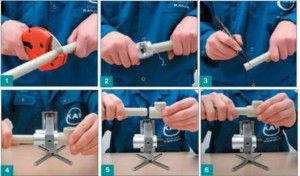

The determining factor in the quality of heat supply is compliance with the installation technology. Even the most expensive polypropylene reinforced heating pipes can not last long if the rules were violated during their installation. The minimum set for connecting polypropylene pipes includes a soldering iron with a set of heads, scissors and a device for processing the ends. The latter is a mandatory component, since to form a reliable welded joint, it is necessary to remove part of the reinforcing layer at the end of the pipe.

The sequence of installation of German polypropylene pipes for heating:

- After the acquisition, they should lie for a while in a room with a temperature of + 15 ° C to + 20 ° C.

- According to the compiled scheme, pipes of a certain length are cut off.

- Before soldering, degrease the ends. Short-term exposure to polypropylene pipes for heating Kalde with acetone or industrial alcohol is allowed.

- After heating the mirror of the welding machine to the desired temperature, the ends of the fitting and the nozzle are inserted into the nozzles. At this stage, it is important that the dimensions of the polypropylene pipes for heating correspond to the nozzles. A temperature effect of a strictly defined time is also necessary.

- When the polymer surface softens, you can install the pipe in the fitting. It is important not to rotate the joint until it has cooled completely.

You can determine the optimal welding time for polypropylene pipes for Valtec heating according to the manufacturer's recommendations. It depends on the diameter of the product, as well as the wall thickness. If it is difficult to find out this information, you can use the data from the table.

|

Pipe diameter mm |

Time for heating, s |

Time for welding, s |

Cooling time, min |

|

16 |

5 |

4 |

3 |

|

20 |

5 |

||

|

25 |

7 |

||

|

23 |

8 |

4 |

|

|

40 |

12 |

6 |

The step of their fastening depends on the choice of polypropylene pipes for heating. For products with a diameter of 16 to 25 mm, it can be 60 cm. If 40 mm pipes are used in the heat supply, the recommended step is 110 cm. On straight sections with a length of more than 1.5 m. compensation loops are installed. They are necessary to relieve surface tension after installing the heat supply from polypropylene pipes with your own hands during operation of the system.

Hidden installation in gates is not recommended. In this case, upon completion of the installation of the heat supply system with polypropylene pipes, there is a high probability of failure, since external pressure will appear when the surface expands.

Polypropylene Heating Pipe Manufacturers

One of the indicators of the quality of heat supply from polypropylene pipes in a private house is the manufacturer. The manufacturing technology of this product is quite laborious. But the emergence of a large number of low-quality pipes indicates the expansion of the "gray" production market.

During the selection you should pay attention to several details. First of all, it is the presence of marking of polypropylene pipes for heat supply. In addition to the technical parameters, the manufacturer must be indicated on it, as well as the regulatory document according to which the product was manufactured. But experienced craftsmen first recognize the brand and then check if the reinforced polypropylene pipes for heat supply are fakes.

Currently, there are several manufacturers whose products are fully credible and different from the rest in quality. Despite the fact that this is more typical of German polypropylene pipes for heating, high-quality products of domestic manufacturers are on the market.

Polypropylene pipes Rehau

Currently, polypropylene pipes for heating Rehau are the sales leader.The German company for a long time earned the image of a reliable manufacturer, whose products meet modern quality standards. Therefore, when planning the installation of heating from polypropylene pipes with their own hands, they most often opt for this brand.

For heating, the company offers the following models of polymer pipes:

- Rautitan pink. Universal option for heating any type. A distinctive feature is pink;

- Flex. This model is adapted for the selection of polypropylene pipes in heating with a maximum pressure of up to 10 atm;

- His. Pipes can be used for heat supply with water temperature up to + 70 ° С, as well as in hot water supply.

Additionally, Rehau manufactures a series of professional installation tools.

Kalde Polypropylene Pipes

The Turkish company Kalde relatively recently appeared on the domestic market. But a responsible attitude to quality and a sufficiently large range of products allowed her to gain confidence. For the organization of heating, you can purchase the following models of polypropylene pipes for heating Kalde:

- Reinforced with foil aluminum. They belong to the economy category. But despite more than democratic value, marriage is low;

- Fiberglass reinforced. Designed for operation in high temperature systems ..

A distinctive feature is the use in the manufacture of polypropylene grade PP-b. Reviews of polypropylene pipes for heating from this manufacturer indicated the preservation of integrity even when water freezes.

Polypropylene pipes for heating Valtec

From the very beginning of production, the Italian company Valtec has emphasized the versatility of its products. But this was carried out taking into account world requirements for quality and operating conditions. Due to this, Valtec polypropylene pipes for heat supply have a seven-year warranty.

The main models for installation in the heating system:

- PP-FIBER PN 20. Designed for operation in systems with a nominal pressure of up to 6 bar. The maximum temperature of hot water can be + 90 ° C;

- PP-FIBER PN 25. It differs from the above only in higher maximum pressure - 9 bar at the same coolant temperature.

Pipes from this company can be used for heating in production. Their surface has increased protection against the influence of many chemical components.

Reviews of heating with polypropylene pipelines

Often reviews of polypropylene pipes for heat supply make it possible to find out the intricacies of installation and operation. That is why it is recommended that you familiarize yourself with their contents before purchasing and installing:

- I thought for a long time about the scheme for installing polypropylene pipes in a one-room apartment. As a result, he will stop on the version with gates. It is good that they warned in time that they should not be plastered after installation. First blow out the foam. It should compensate for thermal expansion;

- I always thought that the main advantage of polypropylene pipes is their installation. But after I installed them instead of steel, there were concerns about the operation of heating. I have an old solid fuel boiler, which sometimes heats water strongly. Friends advised putting the mixer on the supply and return pipes so that the plastic would not melt;

- Remember that polypropylene pipes cannot be installed on the boiler inlet pipe. We decided to do the installation ourselves and made this mistake. After the first start of heating, the pipe “flowed”. As it turned out later, first a steel pipe is installed from 1 m long, and then polypropylene.

Polypropylene pipes are the most common option for arranging heating, both in private houses and in apartments.In order for the heat supply system to work without failures and breakdowns, it is necessary to follow all installation rules, select the appropriate model of the polypropylene pipe.

In the video material, you can familiarize yourself with the test procedure for polypropylene pipes for heating: