Warm floors can be a pleasant addition to the heating system or used as the main source of heating. Depending on the purpose and type of room, one of the available options is selected. The possibility of installing a water heated floor is limited in apartments, the electrical system is universal. It is easy to install and fits various flooring.

Varieties of electric underfloor heating

The universal version of the heating system can be used in any room, including a balcony. Electric underfloor heating is laid under tiles, laminate or wood. Each manufacturer indicates the types of finish that are permitted. Types of electric underfloor heating differ among themselves by the arrangement of heating elements.

Cable

The easiest and budget option is to use a heating cable. The temperature rises due to the heating of metal cores with the passage of electric current. There are for cable type:

- Resistive - consists of one or two cores, a protective braid and insulation. Evenly heated over the entire length. A single-core wire requires laying two ends at the same point. The twin-core version does not have such installation restrictions.

- Self-regulating - a semiconductor matrix complements the copper conductors of the wire. A special screen stops electromagnetic radiation. The temperature in different sections of the wire depends on the environment.

The cable heating element can be laid in the room of any configuration. Of the minuses: the need for mounting in the screed and the complexity of the repair.

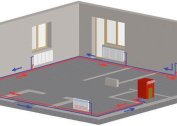

Heating mats

Improved use of heating cable. The wire is already laid in turns and mounted on a fiberglass mesh. Models with single-core and two-core cables are available. Mats are sold in rolls and have couplings for connecting a thermostat. They can be laid on separate sections of the floor that need additional heating. The system works on the principle of convection - warm air flows up to the ceiling.

When choosing mats, complex calculations are not required, their power is known in advance, it is indicated in the passport. In order not to lose the height of the room, laying directly into the layer of tile glue is allowed. The small thickness of the mats and ease of installation make them the best option for a tile coating.

Infrared

The infrared floor system is ahead of convective models in uniformity and speed of heat propagation. It is a thin multilayer film consisting of several elements:

- carbon heating plates;

- copper or silver conductive conductors;

- substrate;

- PVC protective layer.

IR film is used under a laminate, linoleum, carpet or wooden floor. Its thickness is about 0.4 mm. The room is heated due to infrared radiation, while the air does not dry out. The advantage is dry installation without screed and glue. The film can be cut into sections along the intended lines.

Thanks to the parallel connection of infrared bands in the event of a breakdown of one part, the entire system does not fail.

Advantages and disadvantages of underfloor heating

The popularity of electric floor heating is due to its many advantages:

- Comfortable heat distribution scheme. Due to the operation of the system, the entire floor surface is heated. A large recoil area ensures the same temperature in different parts of the room. When using radiators, the floor remains cold, which makes the owners of the apartment or house uncomfortable. With cable and infrared heating, the situation is radically changing. The most pleasant temperature is below.

- Flush mounting - the system does not violate the interior of the room, does not require free space.

- Due to the low temperature, convection flows from the heated surface are weak, they do not raise dust microparticles.

- Versatility - electric floor heating can be done in any room. The design does not make the floors heavier, does not require the approval procedure.

- With professional installation, the system is fireproof.

- Electric underfloor heating are equipped with fine adjustment devices that allow you to individually select the temperature.

Installation of heating mats or infrared film will not cause difficulties. The owner of the house can handle the installation himself.

The disadvantages include the cost of electricity, the complexity of repairs and raising the floor level when laying the heating cable.

How to choose a tiled electric floor

The combination of a warm floor and ceramic tiles is comfort and aesthetics in the house. When choosing a heating structure, its power and operation features are taken into account. Infrared film, in spite of its effectiveness, is not suitable for tiling. High humidity and aggressive environment negatively affect the condition of the infrared floor. Two options remain: cable or mats.

Key customer requirements:

- durability and reliability;

- economical energy consumption;

- efficiency;

- accessibility of installation;

- affordable cost.

The first advice when choosing is to buy products of a well-known brand. Rating of brands will help determine the purchase. Among manufacturers of underfloor heating companies are popular:

- Devi - electric heating systems have a thickness of 2.5-4.5 mm, which slightly increases the floor level. Mats manufacturer have different capacities, they are designed for installation in rooms ranging from 0.5 to 12 square meters. m

- Thermo - the heating cable is reliably shielded, which reduces electromagnetic radiation. Swedish company thermomats are available with an adhesive base or a layer of foil. To control the temperature in the kit there is a thermostat.

- Teplolux - the products of a Russian company are presented in a wide range of options for apartments, houses and offices. The heating system is equipped with everything necessary for easy installation. The company warranty is 50 years.

- Rehau - a two-core self-regulating cable has double insulation and a protective braid. German floor heating systems in the form of mats have a self-adhesive base, which simplifies installation.

Recommendations for choosing a system depend on the type and area of the room. In a large private house, it is advisable to use heating mats, and for quick installation in the apartment a film warm floor is suitable, which does not require significant installation costs.

The purpose of the system is also important - the main or additional source of heat. In the first case, the general heat loss of the room and the climate in the region are taken into account. The average rated design power is 120-180 W / kV. m. Finishing is one of the decisive factors. Find out if it is compatible with the underfloor heating system.

DIY mounting technology

Manufacturers of electric underfloor heating systems give installation instructions. Acting on it, you can independently perform styling, saving money.For any type of heating, foundation preparation is required. It should be smooth, properly insulated, protected from moisture.

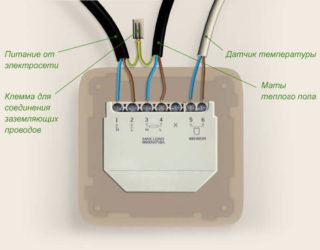

Installation of underfloor heating with mats

Installation of an electric heated floor begins with a plan. It is necessary to draw a scheme for laying mats, excluding places where bulky furniture is located. At the design stage, a place is chosen to place the thermostat. With a high power system (mats occupy an area of more than 10 square meters), a separate line from the distribution panel will be required. Under the temperature controller and the temperature sensor wires in the wall, a vertical channel is made. The control device is located at a height of 30-100 cm from the floor. A junction box is mounted under the thermostat and wires.

Under the sensor wire, a strob is prepared in the floor. It should be located between the turns of the heating element. This position allows you to correctly determine the temperature. To protect against moisture, the device is placed in a corrugated tube, the end in the floor is closed with a plug.

Step-by-step instruction

The first stage of work is the preparation of the foundation. The best option is to make a concrete screed. If a robust structure is already available, it must be leveled and cleaned. Any surface drop leads to damage to the heating cable over time. A good option is to fill in a layer of self-leveling mixture. After the solution has dried, they begin waterproofing. Moisturizing paste or liquid glass will protect against moisture.

An important step is thermal insulation. Heat loss leads to high heating costs. To save money, it is necessary to lay a quality insulation. To isolate the base use:

- Styrofoam;

- extruded polystyrene foam;

- hard mineral wool slabs;

- foamed polyethylene.

The thickness of the layer depends on the location of the base. Insulation of 100 mm is laid on the floor on the ground, 30-50 mm is enough on the floor floors. A popular option was the substrate with an aluminum coating. The foil effectively reflects thermal energy. Penofol cloths are laid back to back, glued with metallic tape.

Laying mats

Heating mats are laid according to the intended scheme. A prerequisite is an indent from the wall of 10 cm and 15 cm from the radiators. If necessary, turn the mat 90 or 180 ° to make a cut along the fiberglass. Do not violate the integrity of the heating element. Upon completion of installation, the system is connected to the mains to verify operability. To evaluate the result, 10 minutes are enough. Then the electricity is turned off and the installation of the tiles is started. It is required to wait for the wires to cool.

The flooring is laid on a heat-resistant adhesive solution. The most popular product is cement-based. The adhesive composition for the underfloor heating must have high elasticity and not crack when heated. Recommended brands: Knauf Flex, Litoflex K80, Unis Plus, Ceresit. The dry mixture is diluted with water according to the manufacturer's instructions. Preparation is carried out immediately before use.

The adhesive mixture is applied to the entire surface of the heating mats in a uniform layer. The cable must be completely hidden. This will protect it from mechanical damage. To apply the composition to the tile, you need a comb spatula. Tiles are laid directly or diagonally, depending on the design decision. In the process, the construction level checks for differences. After the adhesive mixture has dried, a system check is carried out again. It will require more time, it is necessary to warm up the layer of the solution and the ceramic tile itself.

Installation of a floor with infrared heating

Laying an electric infrared warm floor is carried out in a dry way, without screed. You will need a stroba and a corrugated tube to lay the wire of the thermoregulating element. The device itself is placed in a standard box for outlets. The temperature regulator is installed 50 cm from the floor. To connect the film system, a separate electric copper wire and an automatic machine are required. When drawing up a layout diagram, a place is selected for the temperature sensor. It should be in the middle of the film web.

When installing, observe the following rules:

- The film is cut only along the marked lines.

- Between adjacent strips should be at least 50 mm.

- Rolls are placed along the long wall of the room to reduce the number of joints.

- Places of cuts of conductive tires are isolated by the tape that comes with the kit.

Before starting work on laying the IR system, alignment and high-quality cleaning of the base are performed. As a thermal insulation, a substrate made of foamed polyethylene with a foil coating is recommended. The insulation is laid with the aluminum layer up. It is attached to the base with double-sided tape.

The infrared film is placed with copper tires down, the strips are fastened together with masking tape. The same material is used for fixing to the substrate. To connect the heating elements to the electrical network, clip-on terminals are used. They are inserted into the contact section and clamped with pliers. All contact groups are insulated with bitumen tape. It remains to connect the system to the thermostat and check its operation. When laying an IR film under a tile, a glass magnesite sheet spreads over it.

Rules for the use of underfloor heating for tiles

After the installation of heating will have to wait about 30 days until the screed is completely dry. Do not worry that the surface of the tile does not warm for a long time. It will take several hours for the whole cake to warm up. Experts give some tips on the operation of the heating system:

- The floor should not be carpeted, bulky furniture without legs. In such areas, overheating and cable failure occurs.

- Mechanical impact on the flooring of the room is prohibited.

- If you plan a long-term departure, the thermostat is set to a minimum.

- In the event of a breakdown, all work is carried out after the system is de-energized.

- It is impossible to adjust the device of heating cables, sensors, thermostat.

- Installation of heating elements is carried out in soft shoes to avoid damage.

After installation, photograph the cable management diagram. The information will be useful to specialists in case of breakdown of the underfloor heating.

With an electric heated floor, life will become truly comfortable. In severe frosts and off-season, when heating is not turned on, the tile will give pleasant warmth.