For the modern user, the heating scheme of a private house with an electric boiler is of practical interest when it is necessary to independently mount the purchased equipment. Even before its acquisition, you will need to deal with the types of heating boilers, as well as with the features of their installation and connection. It is also important to correctly assess the advantages and disadvantages of boiler equipment installed in a country house.

Advantages and disadvantages

The advantages of heating in private houses with electric boilers include:

- comfort created by heating conditions at a minimum cost;

- high efficiency with relatively small sizes;

- ease of installation, taking into account a well-chosen place;

- unpretentiousness in leaving and safety of operation of a boiler;

- wide selection of capacities and environmental friendliness.

Thanks to these features, it is easy for the user to choose a model that is optimally suited for heating rooms of any category. The advantages of electric boilers include their relatively low cost. Operational safety is manifested in the absence of an open flame, as is observed in gas boilers, and environmental friendliness - in the absence of combustion products that pollute the environment.

The minus of electric boilers is considered to be large energy consumption and the need to ground the housing. To solve the first problem, it is possible to purchase equipment with a built-in storage buffer. The second is removed by arranging a reliable grounding circuit located on the personal plot of a one- or two-story house.

Boiler selection

The main criteria for selecting units for private consumption are their thermal power, the characteristics of the supply network and the method of electric heating. According to the last sign, all electric boilers have the following designs:

- heating devices equipped with built-in heating elements;

- electrode assemblies;

- induction boilers.

- Induction

- Heating element - TEN

The first models on the list are the most common, due to their low cost and ease of maintenance. The indisputable advantage of such boilers is the safety of operation. In case of depressurization of the heating system and leakage of coolant from it, the protective mechanism disconnects the heater from the network, after which the heating of the water stops until it is filled again.

In electrode boilers, a well-known physical phenomenon called electrolysis is realized. When an alternating current passes through an electrolyte due to the random collision of ions, the electrical energy is converted directly into heat. Due to direct heat generation, the efficiency of such boilers is very high. On the other hand, these units need constant monitoring of the state of the thermal environment, which complicates the control system and increases the cost of equipment.

The principle of operation of induction boilers is based on the phenomenon of electromagnetic induction. When current flows through a winding wound on a ceramic tube, the ferromagnetic element located inside is heated by the action of a vortex field. Heat is transferred from it to the water carrier.

The advantages of induction-type boilers include their relatively small dimensions and durability. Like equipment equipped with heating elements, these products are able to work with any type of coolant (water, antifreeze, distillate, etc.).

Choosing an installation location

Existing standards do not provide restrictions on a specific installation site of an electric boiler. It is selected for reasons of safe operation, taking into account its extreme characteristics (maximum power) and must satisfy the following requirements:

Existing standards do not provide restrictions on a specific installation site of an electric boiler. It is selected for reasons of safe operation, taking into account its extreme characteristics (maximum power) and must satisfy the following requirements:

- the ability to limit the access of residents to power equipment;

- the presence of a separate line with a junction box that allows you to connect powerful power equipment;

- the possibility of grounding the boiler body.

To fulfill the first requirement, it makes sense to install a powerful outdoor unit in isolation - in a garage or utility room. Compact wall-mounted models can be placed in the kitchen or next to the input device. Particular attention is drawn to the possibility of connecting the heating main with battery wiring. In addition, the chosen location should provide easy access to the unit in case of repair or maintenance.

Optional equipment

The strapping of electric boilers is equipped based on the use of the following required elements:

- The circulation pump used to move the coolant along the heating circuit in order to transfer heat energy to batteries that can heat the surrounding area.

- Expansion tank, designed for temporary accumulation of excess coolant during its overheating.

- Pressure gauge used to monitor system pressure.

- Automatic air bleed device (Mayevsky crane).

- A safety valve that works only in emergency situations - when boiling water carrier, when the pump stops or the tank is full.

The operating procedure of the last element provides for the discharge of excess coolant into the sewer.

According to the standards, when installing an electric boiler, it is mandatory to install a safety group that duplicates the functions of some devices.

Schemes of the heating system with electric boiler

Depending on the design of the unit and its functionality, the connection schemes of the electric boiler to heating systems will differ. The following options are possible:

- In the presence of pumping equipment and an expansion tank, a more complex scheme of an electric boiler for heating will be required.

- Its simplified variety is in demand if these components are not.

- A completely different option is needed if the piping system has a buffer tank or a connection to an indirect heating boiler is required.

- A special switching method is used when using the solid fuel boiler and electric boiler connection scheme in one system.

A completely different approach will be required when combining equipment with a gas boiler. When choosing a dual-circuit unit in the circuit solution, you will have to provide a line for connecting to the heating and domestic hot water lines.

DIY connection and launch

The specific scheme for connecting the electric boiler to the heating system is selected taking into account the following considerations:

- It is allowed to connect heating units with power up to 3.5 kW to a power outlet.

- To heat a house with an electric boiler up to 7 kW, you will need to connect its power cable directly to the machine installed in the distribution panel.

- Samples of boiler equipment with a declared power of up to 12 kW are usually connected to a single-phase network with a voltage of 220 volts.

- For units of greater energy intensity, a 380-volt three-phase supply line will be required.

Before putting into operation, it is mandatory to check the connection of the corresponding components of the electric boiler to the heating circuit.

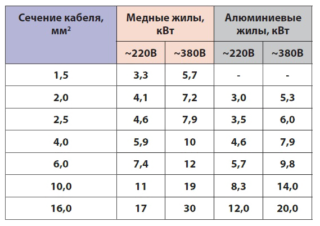

According to the requirements of the PUE, the unit is connected to the power grid through a bunch of RCDs plus a circuit breaker, selected from the calculation of the rated current consumption. The value of the latter is indicated in the passport of the installed equipment and is taken into account per phase. The cross section of the cores of the power cable is selected according to special tables and depends on the power of the connected unit.

Trial run

Before starting up the boiler, you will need:

- Check the reliability of electrical contacts and the tightness of the couplings, as well as the absence of leaks in the valves and pipe joints.

- Fill the heating system with coolant using the make-up tap.

- Bleed the air from the system through a Maevsky cock or similar device.

When starting up, the pressure in the system must be monitored using a pressure gauge built into it.