In order to heat cold water for paired procedures, you can use a boiler apparatus or install a tank that will transfer heat generated by the stove to the liquid. For the operation of the installation to be safe and efficient, you need to know how to properly connect the tank to the heat exchanger in the bath.

Types of water tanks

When taking bath procedures, there is a constant need for water. It is needed for pouring stones in the stove, processing brooms, washing the body after staying in a steam room, and maintaining cleanliness in the room. Therefore, it is necessary that there is always a heated liquid nearby. In summer cottages, where baths are often built, often there is no possibility of using main hot water supply. To solve the problem, a hot-water tank is connected to the heat exchange element.

Tanks differ in execution, materials used, dimensions and shape. There are models on sale that are specifically designed for use in the sauna. Tanks with a water circuit are usually made of stainless steel or galvanized sheet.

Built in

In the past, such water tanks were equipped in bathhouses already in the process of their construction. When connecting the bottom of the tank to the furnace, the liquid was heated from the heat of the oven. The advantage of this design is its high heating rate. The minus is the decrease in the heat transfer of the furnace unit to the air masses (since most of it goes to the preparation of the liquid). Water is taken from the tank with a scoop or a tap is installed. The capacity of the resulting tank is determined by the size of the furnace.

Remote

The convenience of connecting a remote tank to the sauna stove consists in the possibility of choosing from several locations for the container. Usually they put it in the shower room next to the steam room. The heat exchange element mounted in the furnace is responsible for heating the liquid. It is connected to the tank through brass or copper pipes. A cold liquid flows through the heat exchanger, and back - already heated.

On the pipe

Here, the water is heated by the heat of gases moving through the chimney. Installing such a tank is more difficult than other types, but its use has several advantages. The liquid heats up very quickly, and a large capacity allows you to serve a company of 5 or more people. Water retains heat for a long time even after the end of the furnace. Often tanks are installed in the attic. Such placement is advantageous in that it allows you to leave more free space indoors. The material for the container body is most often stainless steel, which also contributes to the speedy heating of water. But at the same time, you need to make sure that the liquid does not start to boil (this applies to tanks of any kind).

The attached

In this case, installation operations to connect the tank to the heat exchanger will not be required. The capacity is attached to the furnace wall, the liquid in it is heated by the heat of the furnace unit.

The attached design is attractive due to its simplicity, but the preparation of water in it is not as fast as in others. Nevertheless, it is suitable for a steam room, which is used simultaneously by no more than 2-3 people.

- Remote

- On the pipe

- The attached

Tank materials

Hot water tanks are made of different metals. Cast iron tanks were widespread in the past. Over time, they were replaced by tanks made of lighter materials - steel and aluminum.

Stainless steel

This metal replaced heavy cast iron. The liquid in the steel tank heats up very quickly. The material tolerates temperature extremes. Tanks do not require protection against high humidity. The only drawback is that water does not retain heat for very long.

Cast iron

In the old days, this was the only material used to make hot water tanks. Cast iron is good for durability, resistance to corrosion and temperature changes. The liquid in such a tank remains heated for a very long time. Nowadays, cast-iron tanks are almost not produced due to their heavy weight, but there is an opportunity to purchase a used tank at a more affordable price. Mount a cast-iron tank under the stove. For large-sized options, it is necessary to prepare the foundation. In addition to weight, the disadvantage is a rather long heating of the water.

Other metals

For the production of hot water tanks, enameled steel is used. The coating provides protection against corrosion damage to the product. The surface is easily cleaned of dirt, but it is important not to violate the integrity of the enamel layer, otherwise rust may appear on the container. On sale you can find tanks with a coating of different colors. They make water tanks from flexible and lightweight aluminum sheets. This design is easy to do at home. To prevent surface corrosion, galvanizing is recommended.

Wood and plastic

The operational characteristics of these materials allow their use only for tanks with non-hot water. This is especially true for plastics that melt from exposure to high temperatures. If there is no water supply in the bath and there is a need for a container for warm or cold water, you can use wood or polypropylene products.

Plastic buckets or buckets should not be placed next to the stove, otherwise they may become deformed.

Advantages and disadvantages

A tank of sufficient capacity will provide residents with heated water for hygienic procedures and household needs. The liquid in the container eliminates the problem of dry air. Compared to gas or electric water heaters, the advantage of using a tank is the lack of additional resource consumption. The connection of the tank to the stove will help out in case of temporary disconnection of the supply of main resources.

Cons of tanks depend on the material and type of construction. In steel tanks, water cools quickly, cast-iron are heavy. Mounting a tank on a pipe requires special skills. The thickness of the walls of the product affects the heating rate.

Dimensions and shapes of water tanks

If the steam room is small and suitable for finding two people at the same time, it will be enough to install a capacity of 40-50 liters. To service an entire company, a massive tank (about 100 liters) will be required. You can calculate the required volume if you imagine the number of people who simultaneously take bath procedures regularly. It is multiplied by 10 and add a spare 20 liters.

In addition to traditional rectangular shapes, there are triangular tanks. Pipe mounted models can be designed for horizontal positioning. Sometimes they have rounded corners.

Installation and connection of the water tank to the heat exchanger in the bath

The nature of the installation of the tank in the bath depends on how the water will be heated - from the furnace heat or by means of a tubular electric heater. If the building has water supply, a closed water supply is used. In this case, a stove equipped with a serpentine element is better. The latter is connected to the tank and heats the water.If the tank is small and light, it can be hung on the wall or directly above the stove. The easiest way to install an attached tank.

The nature of the installation of the tank in the bath depends on how the water will be heated - from the furnace heat or by means of a tubular electric heater. If the building has water supply, a closed water supply is used. In this case, a stove equipped with a serpentine element is better. The latter is connected to the tank and heats the water.If the tank is small and light, it can be hung on the wall or directly above the stove. The easiest way to install an attached tank.

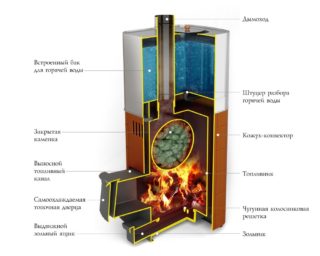

When using a furnace unit with a coil, the connection diagram of the heat exchanger in the bath to the tank will look like this:

- The container is installed in the planned place and connected to the pipes by means of a serpentine element.

- The upper and lower part of the tank must be connected to the corresponding branch of the element - then the cold liquid comes from below, and the heated goes from above.

- In the area of water supply for heating, valves are put - check and safety. For them, it is necessary to determine the pressure indicators that trigger the operation.

- On the tank, you need to mount an explosive that releases excess pressure that occurs when the heated water is in the tank for a long time.

To prevent the walls of the tank from being unduly exposed to high temperatures from the furnace, they are recommended to be insulated. This will help the water tank last longer. It is possible to put a sheet of asbestos between the unit and the tank.

Installing a liquid tank in the bath will save fuel resources. Dimensions are selected depending on the area of the steam room and the number of people regularly visiting it.