A pyrolysis boiler is a heating equipment designed to heat homes, cottages, and various rooms. The principle of operation is based on the release of pyrolysis gas and its combustion.

The device and operation of the pyrolysis boiler

Units that allow gas to be obtained by pyrolysis of wood are called gas generators. Firewood is placed in a closed tank, it is also called a fuel chamber or reactor.

Units that allow gas to be obtained by pyrolysis of wood are called gas generators. Firewood is placed in a closed tank, it is also called a fuel chamber or reactor.

The principle of operation of the pyrolysis boiler:

- Fuel is put into the furnace, and then it is ignited. Initially, the raw materials burn like in a conventional boiler, but when the temperature is reached over 200 degrees, the air supply valve to the combustion chamber closes, and the active phase of wood pyrolysis begins in it. As a result of decomposition, wood gas is actively released, which is discharged using an outlet pipe.

- At the next stage, active heat generation begins - exothermy. The accumulated gases are condensed and fed into the afterburner, where they interact with air.

Thanks to the auto-shutter, the temperature is automatically regulated.

Types of pyrolysis boiler

There are several types of equipment depending on the location of the afterburner and the type of ventilation.

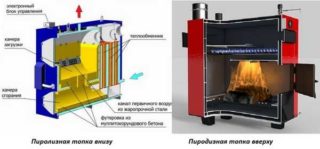

With bottom burnout chamber

This modification is the most common due to ease of use. Fuel is laid in the upper chamber. The evolved gases exit into the pipe below.

The main disadvantage is the need to clean the system often.

With upper burnout chamber

Such devices are less common, but have undeniable advantages. Ash does not penetrate the annealing compartment, so there is often no need to clean the boiler. Thanks to the nozzles, the gases are discharged upwards, where they are burned and enter the chimney. Such a system is more practical.

With natural ventilation

The peculiarity of such units is that their performance does not depend on the supply of electricity. To create good draft, the boiler must be equipped with a sufficiently high chimney.

Forced ventilation

Pyrolysis boilers with forced ventilation are volatile, since the design is equipped with pumps and fans that operate in automatic mode.

A characteristic feature of energy-dependent modifications is a longer effective burning time compared to natural ventilation boilers.

Advantages and disadvantages

Pyrolysis units, like other types of heat sources, have advantages and disadvantages. Of the advantages should be highlighted:

- When burning fuel, thanks to the principle of operation of the unit, it is possible to achieve an efficiency of 90-93%.

- Types of plants that operate on natural draft, do not depend on the availability of electricity in the network.

- The process is environmentally friendly, a small amount of harmful substances is released into the atmosphere.

- Profitability. The consumption of solid fuel per 100 sq. M with a ceiling height of 3 m is about 10 kg of raw materials per day.

Disadvantages of pyrolysis boilers:

- A fuel with a low moisture content is needed (firewood moisture not more than 25%).

- The equipment costs slightly higher than a classic solid fuel boiler.

Since the pyrolysis boiler operates at relatively low temperatures, deposits of tar and tar accumulate on the walls of the chamber. As deposition of the substance must be removed.

Types of fuel for pyrolysis boilers

Long-burning pyrolysis boilers are able to operate on several types of fuel:

- firewood (dimensions should be no more than 450 * 250mm);

- peat;

- briquette;

- coal;

- ground branches;

- sawdust;

- coke.

The most effective type of fuel is considered to be wood. The raw material during combustion emits the maximum amount of pyrolysis gas. For effective work, it is recommended to use firewood, the thickness of which is at least 70-100 mm. In combination with firewood, pellets and sawdust can be used (up to 25%).

Protective mechanisms of the pyrolysis boiler and operating features

Long-burning boilers are fire hazardous objects, since during operation inside the chamber high temperature values are achieved. During use, it is important to observe safety measures:

- The heating system is installed on a brick or concrete base, a metal sheet 2 mm thick is placed in front of the firebox to protect the surrounding area from accidentally dropped coals.

- The boiler is installed at a distance of at least 20 cm from the walls. There shouldn't be furniture nearby.

- The chimney must be insulated to reduce heat loss, reduce the formation of condensate and the precipitation of tar in the sediment.

A safety group is mandatory for installation: a manometer, an automatic air vent, and also an emergency valve for bleeding air at overpressure.

DIY boiler

To build a boiler with your own hands, you need to prepare working equipment:

- electric drill;

- thermal sensor;

- welding machine;

- fan;

- several packages of electrodes;

- several strips have become of different sizes;

- Bulgarian;

- grinding wheel 125 mm;

- set of professional pipes 2 mm;

- 230 mm cutting wheel;

- metal sheets 4 mm.

An example will be considered the algorithm for making the boiler with your own hands from a gas cylinder. The optimal volume of the tank is 50 l.

Step-by-step scheme of actions:

- Cut off the upper part of the container, remove the rounded part. After grinding, it will play the role of a cover. The side must be equipped with a fuel inlet. Burnt firewood will fall down through the grate from the reinforcement.

- Weld the chimney. For best traction, it is best to use pipes of different diameters at the beginning and end. For an attractive appearance, the outer part of the chimney can be coated with refractory paint.

- From a pipe and an iron disk, make a piston to which the blades will be welded after. During combustion, the blades rotate and create vortices of air, and the disk prevents the formation of an open flame.

Home-made pyrolysis boilers are also made of metal sheets (the most difficult option) and make a calculation of brick.

Browse Popular Models

A large number of manufacturers offer a wide range of heating devices that work on the principle of pyrolysis fuel combustion:

- "Popov Boilers";

- "Bourgeois K";

- Copper of long burning "Trayan";

- Buderus boiler equipped with a cooling heat exchanger.

The choice of heating equipment must be approached thoroughly, because the quality and convenience of heating a house will depend on this. The average price of pyrolysis boilers is 75-80 thousand rubles.