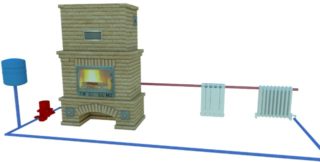

To heat a home in a village without gas supply, a country house or a cottage, a fireplace stove with a water circuit is suitable. The unit runs on solid fuel, provide parallel heating of the room and the coolant in the pipes. Water can be used as a heat source for domestic needs. Before installing the equipment, you need to determine the material of manufacture and deal with the connection technology.

The main types of fireplace stoves with a water circuit

The stove is selected at the design stage of the house. This will correlate the design with other objects, hide its binding. When installing heating units after construction, it builds to consider their varieties.

Steel Models

They differ in affordable cost and ease of operation. The heat exchanger is made of heat-resistant metal with a thickness of 3-5 mm, has no seams. Chamotte, ceramics, cast iron sheets are used for external lining. The fume collector, flame divider and furnace deflector are made of steel or cast iron. The grate is exclusively cast iron.

Due to the flexibility of the material, the structure can be of any shape. Fireclay or ceramic lining increases the life of the stove.

Steel parts undergo corrosion, so you need to heat the furnace in a mode with minimal condensate production.

Cast Iron Fireplaces

The cast-iron type of fireplaces can be connected to a common radiator system and provides efficient heating of a house of any quadrature. The device includes the following elements:

- heat exchanger equipped with a coil - used for water circulation;

- heating circuit - a coil is connected to it;

- a circuit consisting of radiators, expansion tanks, pipes with fittings and a pump;

- open or closed firebox;

- grate - needed for ventilation of air masses and removal of combustion products;

- an ash pan with a sliding tray - ash falls on it when cleaning;

- chimney with smoke collector for fixing.

A cast iron stove does not burn out oxygen in the room, has a high heat capacity and does not cool for a long period of time. When exposed to high temperature, the material does not crack or deform.

Combined Models

Long burning fireplaces are suitable if you have a house with several rooms or a rural cottage. Combined modifications are made with a steel body and cast iron parts, which are affected by fire. Most often it is a firebox and a stove. The corrosion-proof case excludes cracking of cast iron at temperature differences, and cast-iron walls do not allow to melt when overheated.

The design of a long burning fireplace stove with a water circuit for heating is presented:

- a furnace chamber in which firewood is laid;

- a blower compartment with a grate and a sliding ash pan under it;

- pyrolysis gas afterburner;

- a partition between the furnace and the afterburner;

- a chimney pipe where the pipe is discharged;

- a door made of cast iron or heat-resistant glass.

Products are characterized by high efficiency, compactness and durability. Aesthetic appearance and additional heat capacity are provided by ceramic cladding.

Cassette Fireplaces

The cassette fireplace looks like a classic wood burning fireplace. For the manufacture of firebox, frame and walls, steel or cast iron is used. Heating units can work automatically, without constant user control. The finish of the case performs the function of protection and is made of ceramic tiles, natural or artificial stone.

From standard modifications, the product is distinguished by:

- efficiency - typical for closed models;

- universality - due to high efficiency they are used as the main and auxiliary heat source;

- the presence of a contact chimney with a small cross-section and a shortened pipe for quick removal of combustion products;

- cassette elements - the cassette provides quick heating, is equipped with a system of built-in air vents;

- refractory doors made of frosted or clear glass.

For intense heating, a metal distribution disc can be installed.

Depending on the power, dimensions of the equipment and the square of the heated area, you can choose the cassettes:

- for installation in an open firebox: give a minimum of heat, but they are suitable if you have a small cottage of 1-2 rooms;

- for installation in a closed firebox: they differ in power, they effectively heat a large house.

The cassette oven cools quickly, but a brick portal is organized to maximize heat savings.

Angular type water fireplaces

The corner version of the heating units has the shape of a triangle or pentagon. In the first case, there is no oven, and in the second - there is a large hob for cooking.

The rear walls of the fireplace are located relative to each other at right angles. The building is suitable for small rooms, ergonomic and compact. The lower part of the stove is equipped with a wood dryer or a retractable blower. Near the sides there may be decorative bollards made of bricks. The fireplace insert has a semicircular, square, rectangular or trapezoidal shape.

Angular type constructions have several advantages:

- compactness in comparison with wall or island units;

- rationality of using a small room;

- ease of self-installation;

- the possibility of decoration with plaster, ceramic tiles, ready-made portal.

Corner modifications emit maximum heat at minimum sizes.

Pros and Cons of Water Fireplaces

Fireplace inserts and stoves with a liquid heat exchanger have a number of advantages:

- independence from electricity and gas - firewood is used for bookmarking;

- compact dimensions, which is suitable for any area of the room;

- the possibility of using for heating and cooking;

- maintaining a comfortable temperature in a large house;

- uniform distribution and supply of heat to the far rooms;

- high efficiency with minimal fuel costs;

- operation of stoves with a circuit and a tank for hot water supply;

- safety - the outer parts of the casing with the lining do not heat up;

- connection to a radiator heating system.

A stove with a water system has several disadvantages:

- minimum automation of brick and metal models;

- time spent laying a firebox and lighting a fire;

- the formation of soot, soot and smoke when using firewood from conifers, cherries, willows;

- quick cooling of steel modifications;

- not all units are suitable for coal firing.

You can heat the stove with logs from hornbeam, aspen, birch, beech or special briquettes.

Features of the choice, do-it-yourself installation and operation

The fireplace, equipped with a system with a circuit and a boiler, is suitable for water heating of all rooms in the house.It is connected to the system through pipes in the furnace. When buying equipment you need to consider:

- Features of secure installation and connection to communications.

- Power. For a house with a total area of 100 m2, models from 7 kW are suitable, in rooms less than 80 m2, low-power equipment is permissible. It is worth considering that 1 kW of power goes to heat 10 m2 of the home.

- Material. Steel aggregates at an inexpensive cost are more susceptible to corrosion. Cast iron accumulates heat for a long time, but their price is more expensive.

- The presence of a long burning regime. Such devices are energy efficient, have an efficiency of 75-90%.

- Complete set. The standard water fireplace is equipped with an ash pan, chimneys, a chimney, a stove, a heat-resistant sash.

- Possibility of pouring antifreeze into the system. Glycerin solution, ethylene glycol and propylene glycol do not freeze at -30 degrees.

All technical parameters are in the manufacturer's documentation.

DIY installation

The compactness and light weight of the fireplace equipment precludes the construction of a massive foundation. It is enough to make a flooring from sheet material, lay out a tile or other fire-resistant coating. Self-installation is performed as follows:

- Removing the factory packaging and checking the design for integrity.

- Control finished coverage level.

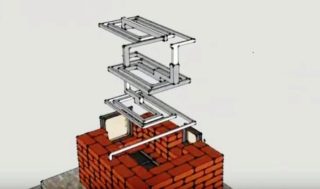

- Removal of the pipe one level with the chimney.

- Assembly of gas outlet elements.

- Installation of grid-irons, ash-pan, lattices and shutters.

- Sealing the connection of the hearth to the chimney, as well as joints and seams.

The single-circuit pipeline is insulated.

Terms of Use

When using fireplaces with a hydraulic heat exchanger, it is necessary to adhere to a number of requirements:

- Cleaning chimney ducts from soot 2 times per year.

- Regular, as accumulation, removal of ash from the furnace and ash pan.

- Drain water from pipes if the system is not used in summer.

- Preliminary inspection of radiators, tanks, pumps, fittings and filters before starting heating.

- Cleaning the glass door with special tools.

- Filling the heat exchangers with water to prevent burnout.

- The supply of warm water in the mode of a heated stove.

- Using a bypass circulation pump to increase system efficiency.

In winter, it is allowed to pour antifreeze in the communication.

Features of connection to the heating system

A water fireplace is connected to the system if there is a coolant in the circuit, taking into account its circulation.

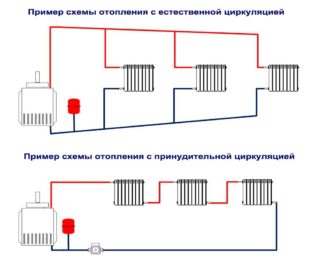

Natural type of circulation

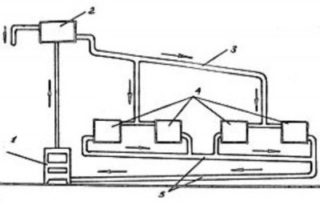

Units with a water circuit are connected as follows:

- Construction of the booster collector behind the heat exchanger to raise the coolant to the highest point.

- Install the expansion tank at the top.

- The construction of the heating line from pipes of at least 32 mm in diameter.

- Compliance with a slope of 5 cm per 1 m for normal circulation.

To connect the system to radiators, use pipes 16-20 mm in diameter.

Forced type of circulation

Forced water circulation provides several nuances:

- an expansion tank is placed on any part of the line;

- batteries are connected in any way;

- it is not necessary to observe the slope of the track;

- an automatic unit can be used to prevent condensation in the firebox.

Place the expansion tank on the return pipe behind the pump.

Overview of popular water circuit fireplace stoves

Modern manufacturers produce water fireplaces for heating small houses and large rooms. Consumers prefer several options:

- Koza / K6, Kratki. Compact heating unit for a small house with adjustable flame intensity. Power is 8 kW, the furnace is made of cast iron.

- Bavaria Three glasses, EcoC fireplace.A stove with an original design of a steel fire chamber glazed on three sides. The chimney is connected from above and behind. A heater with a secondary afterburning mode is able to heat the room for about 6 hours.

- Professor Butakov, Thermophore. Available with a door made of steel, cast iron with a window and a shielded convection pipe system. Suitable for equipping a warehouse, a 1000 square hangar. Efficiency is 80% due to the direction of air into the afterburner with special jets.

- Happy Red, MBS. Stylish fireplace for a room of 45 m2. Made of steel and cast iron in a frame way. The firebox is framed by chamotte, the temperature difference is smoothed out by a vermiculite chipper. Efficiency - 82%.

- PK-01, Vesuvius. A model with a hob will heat a 150-square-meter house. The furnace is heated by an electric fan, heat transfer during prolonged burning is 5 hours. burning intensity is regulated by the blower sash.

- Lava, Guca. A cast-iron device with a heating area of 89 m2 is equipped with two regulators - in the furnace and ash pan. The chimney is connected to the rear or side.

All fireplace stoves are safe, equipped with operating instructions.

A fireplace stove with a water heat exchanger is suitable for buildings of any area. The unit is characterized by efficiency, ease of installation and operation. When choosing it, you need to take into account the power parameters, the specifics of the design and the heated quadrature.