The compact stove, invented in Holland, is the perfect solution for a small house and cottage. For its construction does not require significant effort and money, in addition, it quickly warms up the room. The Dutch stove is a low-cost version of the heating device that allows you to install it on the second floor. The furnace can be folded without problems on its own, without resorting to the masters.

Principle of operation

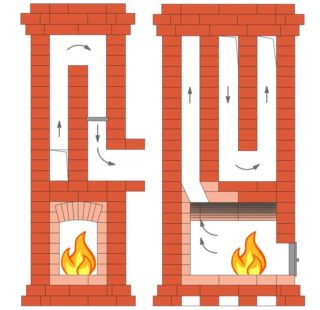

The classic Dutch stove structurally provides for a rather long chimney for exhaust gas. Due to this, a tall structure is obtained, but having a small size in area. Flue gases, which are formed during the combustion of fuel, almost completely give off thermal energy during removal. The cooled air leaves the device through a special side opening.

The smallest furnace of this type - a "counter-oven" with a size of 52x52 cm, can easily heat a room of 20 square meters. m

The principle of operation is that inside the combustion chamber the fuel burns with the lowest intensity. The combustion process is slow, due to which the gases formed pass through the created passages and give all their heat to the brick walls. Such a furnace heats up pretty quickly, but slowly cools down. The surface of the Dutch woman during active use can warm up to a temperature of 60 ° C.

Advantages and disadvantages

The Dutch woman has many advantages:

- takes up little space, which is important for small houses;

- It is created from inexpensive materials, including used ones;

- does not need a powerful foundation;

- heats up rather quickly, keeps warm for a long time;

- can be of almost any height, which has no effect on its performance;

- Looks great in any interior;

- if necessary, equipped with additional elements;

- does not require preliminary heating.

The main disadvantage is the rather low efficiency - about 50 percent. In addition, if after kindling the view remains open, the device will cool off quite quickly. These flaws were leveled by the Soviet engineer Grum-Grzhimailo. He equipped the stove with a grate and a hood. The Dutch cap was very economical and provided good efficiency - over 80%.

Varieties of Dutch ovens

On the basis of a simple Dutch craftsmen are able to create real works of art. The external surface can be finished with tiles, natural stone and other materials. To save space, most stoves are built corner. A variant of the square device is a round Dutch oven. They are more often performed in cases - metal casings. You can buy ready-made units, for example, Weber GBS.

Initially, the furnace was only a heating device. Over time, the design was improved, options began to appear with a fireplace, stove, oven and even with a stove bench. The latter model is usually installed between the kitchen and the living room, which allows the heat after heating the kitchen to move to the residential part, where the owner can relax.

Classic Dutch

A device of this type is an excellent choice for a summer residence. He quickly warms up the room, slowly cools down, easy to install, economical in materials. For the operation of the furnace, it is required to prepare firewood or coal. As a rule, such units are six-channel. Laying is carried out on a foundation in a simple manner.

Fireplace stove

To warm the house and create coziness, the Dutch heating stove is turned into a fireplace. The masonry differs from the classical one in that instead of a cast-iron door, a heat-resistant glass sash of the required size is installed on the combustion chamber. To maintain the fireplace style, the stove-maker rounds the corners of the brick, works out the geometry, increases the foundation and builds an ash-pan and a chimney on the second row of masonry.

With oven

The oven hole is located above the combustion chamber and under the hob. Because of this, the standard dimensions of the Dutch are slightly changed and the cost of materials increases. With its help, you can cook more dishes with the same consumption of firewood. It is difficult to bake cakes in the oven because of the lack of a temperature regulator, but other dishes: bread, pizzas, pies, vegetable and cottage cheese casseroles, meat - get a bang.

Cooking Dutch

To use the stove for cooking outside the oven, on the fifth row of masonry they put a hob of cast iron over the firebox. A clay-based refractory mortar is laid between the metal and the brick. The area above the hob is placed on a metal corner. A Dutch oven with a hob is good in the country for preserving vegetables: it is used to sterilize cans and the finished product.

With water circuit

Such a device heats much more rooms and provides hot water to the entire house. A metal boiler with a coolant is built into the furnace massif, heating directly from the burning of firewood. One pipe leaves the boiler and serves to dilute heated water around the house. The water circuit, passing along the walls of all rooms, returns the liquid back to the heating tank.

- With hob

- With oven

- With water circuit

Tools and building materials

To build a Dutch oven with your own hands, you will need such materials:

To build a Dutch oven with your own hands, you will need such materials:

- raw materials for creating the foundation;

- ligament solution;

- refractory and simple solid brick;

- stove doors;

- sheets of metal;

- steel wire;

- asbestos cord.

Basic tools required: trowel for applying mortar, hammer or sledgehammer for tamping, angle grinder for undercutting bricks, plumb, level, tape measure.

For the construction of the Dutch building material of low quality, and even previously used, will completely pass. When using split brick, the rough side is installed outside. As for the solution, in consistency, it should resemble sour cream. You can create it yourself from sand, clay and water, or buy it ready at a hardware store.

Cement does not have high resistance to thermal effects, so you should not use it for masonry. When the solution is made independently, the clay is broken into small pieces, poured with water and waiting for it to be absorbed. Mix it with sifted sand in a proportion of two to one. Stir well and add water - 1/8 of the total. The preparation of the solution is started a couple of days before the start of construction.

Preparatory work

First you need to create a working draft. Beginners should find detailed schemes of Dutch ovens in advance. You can ask for drawings from professionals. They are on the Internet, with a description of ordinal masonry.

First you need to create a working draft. Beginners should find detailed schemes of Dutch ovens in advance. You can ask for drawings from professionals. They are on the Internet, with a description of ordinal masonry.

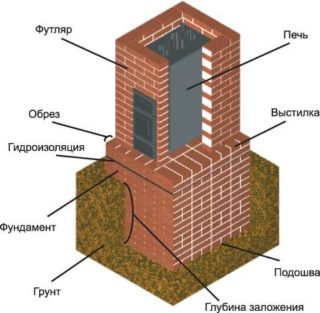

Before building the furnace itself, you need to equip the foundation.

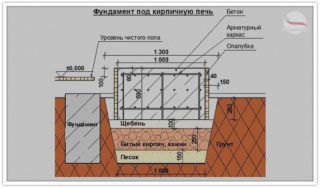

- If the flooring has already been laid, it is removed. Ideally, a place for a Dutch is calculated even at the initial stage of construction of the building.

- A pit is prepared on each side for more than 20 cm than the future furnace, and a depth of half a meter.

- The bottom is covered with a sand layer 0.15 m thick, after which a slab or bricks are laid. All is poured with a thick sand-cement mortar in a ratio of 1: 3.

- Until the cement has set, the surface is reinforced - a reinforcing mesh is laid out with a mesh size of 10 × 10 cm.At the joints, the bars of the reinforcement are vertically installed. The intersection points are fixed using steel wire. A ten-centimeter layer of gravel is poured onto the reinforcing strapping.

- Prepare the formwork for pouring the base. Each side is wrapped with roofing material or hydroisol. A layer of concrete is poured over the gravel and leveled. Wet concrete is sprinkled with dry cement powder and left until final setting.

The foundation should be left to stand for about 30 days. After concrete has completely hardened, a 3-5 cm layer of sand is poured onto its surface and covered with waterproofing material.

Step-by-step masonry instructions

The finished Dutch woman looks like a narrow brick pipe to the ceiling, on which of the external elements there are only firebox doors, a blower and a gate valve. Before starting the installation itself, the masters recommend that beginners first build a stove without mortar, apply the necessary marks and cuts on the bricks. For reliability, you can assign the right number to each brick. To prevent the structure from becoming oblique, you need to pull the plumb lines vertically and constantly use the building level.

The masters also advise to lower the bricks before laying in water for 2 minutes, and wipe the inside of the furnace every 4-5 rows with a wet washcloth or a regular piece of cloth.

The size of the seam for laying the furnace is not more than 5 mm. Steel legs or steel wire are attached to the oven doors, which are subsequently laid in a seam. Installation of all metal elements is carried out together with the masonry.

The order of a simple Dutch 52x52 cm:

- On the roofing material, sprinkled with a thin sand layer, lay the first row of 12 bricks on a dry flat. Check the evenness of the laying by means of a level, fill the surface with a binder solution, smooth.

- Install the blower door by wrapping it with an asbestos cord. To fix the door, take the steel wire. Insert it into the box and twist it doubly. Make a cut in the top edge of the brick. Insert the wire into it, bend it and bind it with masonry.

- Lay the second row of ordinary brick on the mortar, the next ones are already made of refractory material. Between rows 3 and 4, set the grate 200x300 mm.

- In the fourth row and beyond, lay the brick on the edge. Install the firebox door in the same way as the blower. From the fourth to the seventh row, lay the bricks on the rear wall of the furnace in a dry way, so that in the future the combustion chamber was easier to clean.

- Place the seventh row flat of 3/4 brick to increase the reliability of the suture dressing, but put the back wall masonry on the edge.

- For the eighth row, take a beveled brick or a simple one, laying it flat obliquely. Here you complete the creation of the furnace compartment.

- Lay the next rows flat, in the ninth, slightly moving the brick back to expand the chimney. In the tenth, install the base of the metal pipe.

- In the 16th and 17th rows, lay out the cleaning hole and mount the door like a blower.

- From the 18th to the 24th row, form the reverse channels. Make sure the bricks do not protrude.

- 25-28th rows lay out the channel overlap. Slide the bricks a bit. In the 28th row, leave the exit for the chimney channel.

- In the 29th, install the damper, close the chimney in the thirtieth row and remove the pipe.

It will take 14 days to dry. For this period, the firebox door must not be closed. To check the draft in the furnace, it is recommended that you first burn the paper. In the absence of any obstacles to the exit of smoke, the stove is ready for use.

Dutch furnace and safety

To prevent the fire from accidentally fallen coal, the floor in front of the stove is covered with a steel sheet.

If too often drowned - more than twice a day, the room may accumulate carbon monoxide.For heating, do not use quick-burning fuels, because the device operates in smoldering mode.

Regular inspection and cleaning of the combustion channels can prevent soot accumulation and reduce the risk of fire.

It is forbidden to use logs and boards that do not fit in the combustion chamber for kindling the stove. If they protrude, the flame may jump to nearby objects. Furniture and other furnishings should be installed at a distance of at least 50 cm from the stove.

The Dutch is a great way to heat a country house in the cool during seasonal living. It is economical in terms of fuel consumption, it has high heat transfer rates, thanks to this the room quickly warms up. It can also be installed in a small house, which is used constantly, especially in regions with mild winters.