When building a house, one of the important tasks for owners is the organization of efficient heating. One of the most optimal solutions is a steam heating system. The principle of its operation has certain features in comparison with conventional water systems.

Steam boiler operation principle

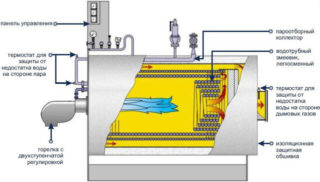

The operation of steam boilers is based on heating the water to a boiling point. After this, it transitions to the vapor state. The whole process is carried out by controlling the water level in the boiler and the formation of evaporation.

Water volume control is carried out using sensors. When the boiler starts, the feed pump starts. It pumps fluid into the heating zone. As soon as the burner turns on, the water begins to heat up, evaporation occurs.

After the volume of water has evaporated, the feed pump starts again. It functions until the level reaches the working mark. The whole principle of operation is based on cyclicality. In addition to working levels, there are also emergency ones. They work as soon as the pressure rises.

Features of steam heating

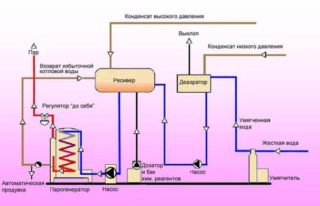

Under the influence of constant pressure, water boils, its temperature always remains constant. As a result of boiling, steam forms, which releases a large amount of thermal energy. When condensation occurs, thermal energy is released into the environment.

According to this principle, a steam heating system operates. Water in the boiler boils, steam begins to move through the radiator and pipes. There, heat is released, due to which the air in the room is heated.

As a result of condensation, water forms, which continues to move through the pipes. She returns to the drive, then with the help of the pump enters the heater.

Varieties of steam boilers

Steam boilers are classified according to the type of fuel used.

Solid fuel

Depending on the type of material used for the operation of the boiler, different combustion chambers are equipped in the devices. Steam boiler houses most often use coal, peat, wood waste as fuel. Industrial boilers operate on this principle. Their main disadvantage is environmental pollution and an increased fire hazard class.

Solid fuel industrial steam boilers are notable for their high power and large dimensions. They are used for food, textile and processing industries.

Electric

The electric-powered steam boiler is widely used in everyday life. The design is equipped with a steam generator, pump, cabinet for energy conversion.

Gas

A steam boiler is the most budget option. Its main advantage is a high degree of efficiency. Condensation-based structures can be used for heating and for domestic use.

- Electric

- Gas

Steam heating circuit

There are various options for heating schemes. They are classified by the following parameters:

- pipe connection diagram;

- system pressure

- a method for transferring heat to the atmosphere;

- condensate return.

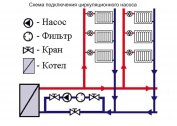

For private homes, household low-pressure boilers are used. Closed and open steam heating systems stand out. When open, communication with the atmosphere is open. In the second form, it is completely isolated from the effects of pressure from the atmosphere.

The steam boiler is divided into one and two-pipe. The purpose of the first type is to organize heating in one-and two-story houses. The two-pipe system is suitable for high-rise buildings and large rooms.

Steam boiler specifications

Steam boilers are very popular among owners of private houses due to the simplicity of operation and a high level of efficiency.

Easy operation

The main advantage of steam structures is easy operation. Units are completely safe for people. The main part of the devices is automated; human intervention is not required for operation. It is enough to study the description and organize the connection correctly. Modern devices are suitable for heating any type of premises. Owners have the opportunity to use different types of fuel.

Cost-effectiveness

Attracts consumers and low cost boilers. At the same time, they retain a high degree of productivity, low inertia. To install a steam boiler, you do not need to purchase additional equipment.

Environmental friendliness

Various types of fuel can be used for the construction to work, thanks to this, the owners select for themselves the optimal options that do not harm.

Silent operation

During operation, the structure does not make any noise, but its level increases as soon as the unit is completely filled with steam.

Operational Features

Particular attention must be paid to the safe functioning of the steam unit. To ensure proper operation, it is recommended that you observe the following rules:

Particular attention must be paid to the safe functioning of the steam unit. To ensure proper operation, it is recommended that you observe the following rules:

- Free expansion for temperature must be ensured. This will ensure uniform heating.

- Observe fluid level. In relation to water pipe structures, this norm is determined by special institutions. Normally, the minimum level should be 10 cm below the heating surface.

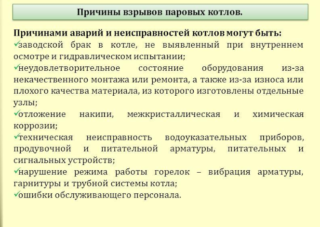

- Device manufacturers equip them with special safety systems to reduce the risk of explosion.

- It is important to monitor the condition of the welds. Their intersection must not be allowed. If defects are detected, a flaw detector will be required.

- During operation of the device, condensation may form in the pipes. It is necessary to purge them. Also, special drains are used to eliminate condensate.

- The vapor pressure in the system must always be monitored. The parameter is measured by a pressure gauge, on which there should be a special mark indicating the testing. Do not use appliances whose verification is expired.

- It is necessary to control not only the pressure, but also the temperature of the water vapor. To do this, thermometers must be installed on all steam pipes.

Steam boilers are characterized by a high degree of reliability, durability and increased power. The use of such devices will effectively provide heating to a house of any size.