The boiler is the main structural element of any heating system. Solid fuel heating boilers are a type of heating equipment. With their help, it is possible to organize heating in any room, including an apartment, a private house or the workshop of an industrial enterprise. The constant increase in prices for the main types of fossil energy carriers, provoked a fairly rapid development of solid fuel boilers. It is the efficiency of such equipment that is considered its main advantage. It is achieved due to the low price of fuel consumables.

What are

All modern types of such equipment are made of heat-resistant steel or cast iron. Each of these materials has certain characteristics. So, steel options have a lower cost and a slightly higher efficiency. As a rule, this superiority does not exceed 2%. At the same time, cast iron boilers are more durable and have the ability to increase power. This is possible by adding standard sections.

All modern types of such equipment are made of heat-resistant steel or cast iron. Each of these materials has certain characteristics. So, steel options have a lower cost and a slightly higher efficiency. As a rule, this superiority does not exceed 2%. At the same time, cast iron boilers are more durable and have the ability to increase power. This is possible by adding standard sections.

Combustion conditions

Under the conditions under which the combustion of fuel occurs, the equipment can be divided into the following types:

- Conventional boilers direct combustion process.

- Boilers with a long burning cycle.

- Pyrolysis or gas generating.

- Boilers that use fuels, processed into a fine fraction of granules.

In a typical solid fuel boiler, combustion takes place in a firebox. In addition to conventional firewood, you can use any type of solid fuel - coal, peat, etc. The combustion products give off thermal energy to the heat exchanger, which transfers it to the heat carrier in the heating system. Of the main advantages of this variant of the boiler, it is worth noting the simplicity of design. Fuel combustion occurs within 2-6 hours.

Long burning process

Equipment that significantly increases the time of the combustion process on one tab, has some design features. The boiler furnace has a cylindrical shape. The combustion process itself occurs in the upper layer and moves down. The thickness of the upper burning layer is about 20 cm. A movable air distributor is located in the furnace of such a boiler. As the layer burns, it drops down, providing the next layer to burn. Air is dosed and is only enough for burning the upper layer. Thus, the continuous operation of the boiler is achieved. Opening hours vary from 12 to 30 hours. In the design of such a boiler there is no ash pan and grate.

Equipment that significantly increases the time of the combustion process on one tab, has some design features. The boiler furnace has a cylindrical shape. The combustion process itself occurs in the upper layer and moves down. The thickness of the upper burning layer is about 20 cm. A movable air distributor is located in the furnace of such a boiler. As the layer burns, it drops down, providing the next layer to burn. Air is dosed and is only enough for burning the upper layer. Thus, the continuous operation of the boiler is achieved. Opening hours vary from 12 to 30 hours. In the design of such a boiler there is no ash pan and grate.

In boilers with a long combustion cycle, it is possible to adjust the power. This is achieved by adjusting the air supply to the sealed combustion chamber. Of the main disadvantages, it is worth noting the demand for fuel quality. The percentage of its humidity should not exceed a value of 30%. The best option is considered humidity of 15 - 20%.

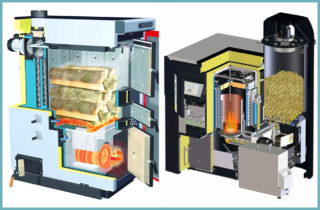

Solid fuel boilers pyrolysis options

The design of such heating equipment provides for two separate chambers. Both chambers are tight. The first chamber provides heating with limited air supply. High temperature and lack of oxygen leads to the fact that the wood begins to decompose, while emitting a large amount of gas. This process is called pyrolysis. It is these gases, preheated and mixed with air, that are burned in the second chamber of the solid fuel boiler.

The design of such heating equipment provides for two separate chambers. Both chambers are tight. The first chamber provides heating with limited air supply. High temperature and lack of oxygen leads to the fact that the wood begins to decompose, while emitting a large amount of gas. This process is called pyrolysis. It is these gases, preheated and mixed with air, that are burned in the second chamber of the solid fuel boiler.

Such equipment is produced in two versions - with the upper arrangement of the gas combustion chamber and with the lower.Designs with the lower location of the afterburner can be found much more often than their counterparts with the upper arrangement of the furnace. With the top location of the fire chamber, it is convenient enough to load fuel. Since the movement of combustion products is not natural, that is - from top to bottom - the draft is carried out in a forced manner. Thus, the design provides for a fan.

Solid fuel pellet boilers

Pellets - pellets pressed from wood and its waste with a diameter of 6 to 8 mm. In addition, agricultural by-products are widely used for pellet production. This is the husk of plants, straw, peat, etc. The main criterion by which the main raw material for the production of granules is selected is the presence of a substance such as lignin. It is lignin that provides the bonding of the mass in the production of this kind of biofuel.

Pellets - pellets pressed from wood and its waste with a diameter of 6 to 8 mm. In addition, agricultural by-products are widely used for pellet production. This is the husk of plants, straw, peat, etc. The main criterion by which the main raw material for the production of granules is selected is the presence of a substance such as lignin. It is lignin that provides the bonding of the mass in the production of this kind of biofuel.

Pellets compressed under pressure acquire a slightly higher density than the raw materials from which they were made. Thus, the specific density of combustion increases. Boilers that use small fraction granules as fuel have design features. The main structural elements are:

- Receiving hopper.

- Pellet feed mechanism to the combustion zone.

- Burner.

- Automatic ignition device.

- Control mechanism with temperature sensors.

In the design of solid fuel pellet boilers, two types of burners are used - flare and retort. In a torch-type burner, the combustion of pellets occurs due to the forced air flow, which forms a flame torch. Retort burners are a volumetric bowl made of heat-resistant steel or cast iron. Through the center of such a bowl is a mechanical supply of pellets. Combustion occurs over the entire surface of the bowl.

Each species has certain advantages and disadvantages. So, torch type burners are simpler in terms of design. The advantages include not demanding on the quality of pellets. The retort type of burners is characterized by greater power and greater efficiency. However, burners of this type are more demanding on the quality of fuel pellets.

Key Development Trends

These trends can be safely attributed to the automation of the combustion process. The process of burning solid fuel is quite difficult to stop. Therefore, situations often arise when the energy output of the boiler does not meet the needs. That is, such equipment is not intended for short-term operation. This drawback can be eliminated by installing a buffer tank in the heating system. It performs the function of accumulating thermal energy with its subsequent transfer to the heating system.

Models of solid fuel boilers, which are produced by modern industry, are a worthy alternative to equipment that uses gas, electricity, diesel fuel as fuel. The designs of modern solid fuel boilers use innovative technologies that significantly increase their competitiveness in the heating equipment market.