Kuznetsov's bell-type furnaces are one of the most popular heating elements today not only in Russia, but also far beyond the borders of the country. Such popularity is explained by profitability and big thermal return. The efficiency of the heating element is approximately 80%. Such a high indicator was achieved due to the new principle of gas movement inside the device.

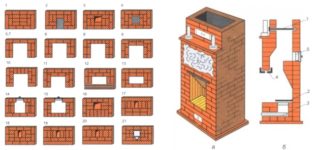

Scheme of the bell furnace Kuznetsov

To build this furnace, you need to adhere to the following scheme:

To build this furnace, you need to adhere to the following scheme:

- The first two rows are laid out in red brick. Their number can be increased to increase the thermal conductivity of the device. To fasten the brick you need to use a special clay mortar. Using a product with cement in this case is irrelevant.

- A blower is built in from the second row, and channels for the chimney are also determined. Front and side of the device are fixed doors that are needed to read the heater. Their fastening is carried out using steel wire, which is mounted in the masonry. To prevent displacement of the structure during heating, basalt wool or asbestos sheet is fixed between the brick and the furnace cast. The thickness of such a gasket should be 5-6 mm.

- The fourth row should be above the blower cover, overlapping it. To make a support for the top layer of bricks, a metal corner is used. It is fixed on the walls of the opening located on the side of the device.

- From the fifth row, the lining of the working area is done. For this, fireclay bricks are used. For this design, it is placed on the edge. To fix the elements, it is recommended to use fireclay clay, since it will not change under the influence of high temperatures. In addition to the lining of the working area, a grate is fixed here. Also at this stage, the first dry seams are made. To perform it, clay mortar is removed from masonry in certain places. In its place, gaskets from any mineral cardboard are fixed.

- Simultaneously with the sixth row of masonry, a furnace door is fixed. In the hardware store you can buy various types of these devices, but for a stylish design it is recommended to buy models of cast iron.

- Rows 7, 8, 9 are laid, while the ninth row should cover the opening of the furnace door.

- Stacking of 10, 11, 12, 13 rows is carried out. On the 12th and 13th rows inside the heating element, catalyst columns are arranged.

- Rows from 14 to 16 are fixed.

- 17 and 18 rows are laid so that the masonry overlaps the lower hood of the heating system.

- On the 19th row, an upper hood with heat exchange channels built-in inside the structure is installed. Four doors are also fixed so that these channels can be cleaned.

- Stacked 20-27 rows.

- On the 28th row, a chimney valve is fixed. Its presence in the structure is necessary in order to prevent the heating element from cooling between the furnace processes.

- On the 29-30th row, the upper dome vault is equipped.

- On the 31 row, a chimney is equipped.

After the manufacture of the heating element is completed, ignition is performed. For this, the minimum amount of fuel is used. At maximum load on the stove, cracks may form inside the device. When testing the appliance, it may begin to smoke. At the first furnace, this is a normal process, since all internal structural elements are heated. If the stove smokes during the next operation, this is not the norm.As a rule, this means that the construction technology is violated. In this case, further operation is not possible. It is first necessary to correct the error and only then use the furnace for its intended purpose. If the heating element does not smoke, the device can be successfully operated on.

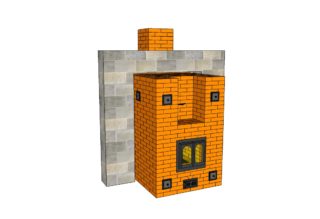

The scheme of the two-bell furnace Kuznetsov

The principle of operation of this heating element is that through the blower, air enters the furnace. Thanks to this, the lightest fuel burns out first, and then more substantial materials. As a result of this, pyrolysis gases burn under the third domed dome. If the flame begins to burn too much, the draft automatically weakens and the flame starts burning more slowly and vice versa - if the fire does not burn well, the draft increases and due to this the flashes intensify. In the two-bell device, a second dome is made so that the combustion process does not deteriorate.

The principle of operation of this heating element is that through the blower, air enters the furnace. Thanks to this, the lightest fuel burns out first, and then more substantial materials. As a result of this, pyrolysis gases burn under the third domed dome. If the flame begins to burn too much, the draft automatically weakens and the flame starts burning more slowly and vice versa - if the fire does not burn well, the draft increases and due to this the flashes intensify. In the two-bell device, a second dome is made so that the combustion process does not deteriorate.

The algorithm for constructing a two-bell furnace does not differ from the scheme of a bell furnace, but has a two-bell design.

Diagram of a heating and cooking stove

Kuznetsov heating and cooking stoves are multifunctional designs. They not only provide heating for the room, but they can also be used for cooking. The design flow chart will be the same as the construction algorithm of the Kuznetsov bell-type furnace, but a hob with a pair of burners is added here. You can also equip an oven and several drying trays. The installation of a heating and cooking stove is relevant in the kitchen or in the dining room or living room combined with the kitchen.

Independent manufacture of the Kuznetsov furnace

The construction of the Kuznetsov furnace is a simple process, but requires certain skills. In the absence of experience in bricklaying, work should be done slowly and very carefully. Here are the basic rules to follow when erecting a structure:

The construction of the Kuznetsov furnace is a simple process, but requires certain skills. In the absence of experience in bricklaying, work should be done slowly and very carefully. Here are the basic rules to follow when erecting a structure:

- During temperature rise, the brick expands. Therefore, the brick should be laid so that the refractory coating on all sides has an empty space.

- To strengthen the strength of the masonry in every third row, it is recommended to fix the metal wire.

- A special gasket must be mounted between the brick and the doors.

- Doors are installed carefully so as not to spoil the appearance of the structure.

- When the heating element is installed, the entire furnace is impregnated with a refractory composition.

Kuznetsov furnace project selection

For beginners who do not have experience with masonry, it is recommended to choose simple furnace designs that do not require special working skills. In addition, they should not design the structures themselves. Only experienced craftsmen can create independent circuits. In addition, they can choose ready-made projects of any complexity.

Material selection

To build a Kuznetsov furnace, you need to stock up on the following materials:

To build a Kuznetsov furnace, you need to stock up on the following materials:

- refractory bricks for arranging a heating element;

- brick for the construction of facing masonry;

- clay resistant to high temperatures;

- purified sand for the solution, the volume of which should be 2 times more than the volume of clay;

- metal wire;

- metal corner;

- molding for the stove, which includes the grate, latches and doors;

- hob with two burners, if a heating and cooking structure is equipped.

In order to be able to operate the furnace for a long time, all materials for the construction should be selected in high quality.

Tool preparation

To build the structure yourself, you will need the following tools:

- plumb line;

- building level;

- trowel;

- spatulas;

- the container in which the solution will be prepared;

- Bulgarian;

- hammer drill;

- nozzle mixer.

Only the availability of these tools ensures quick work.

Preparation of a place for the furnace and arrangement of the foundation

Kuznetsov's stove is installed in the kitchen or in the central room of the house. Before the construction, the foundation should be prepared. The algorithm for its construction will be as follows:

Kuznetsov's stove is installed in the kitchen or in the central room of the house. Before the construction, the foundation should be prepared. The algorithm for its construction will be as follows:

- a rectangular pit is excavated, the depth of which is 1 m, the width is 1 m, the length is 1.5 m;

- the pit is covered with sand, the layer of which should be 15 cm and left for several days so that it “settles”;

- formwork from boards is carried out;

- for reinforcing concrete, a thin rod of metal is laid;

- concrete is poured, preventing the occurrence of bubbles;

- concrete is left to harden for several days.

When the foundation is ready, the structure is erected.

Pros and cons of Kuznetsov furnaces

For normal operation of the heating element, the design must be performed in compliance with all the rules. Only such a furnace has all its inherent advantages, namely:

- high rate of efficiency. It is approximately 80%. If you compare it with the Russian stove, then the efficiency there is only 30%.

- no channel cleaning is required;

- a simple way to heat the room;

- long operational period;

- high efficiency and productivity.

Any heating element has not only advantages, but also disadvantages. Kuznetsov's furnaces were no exception. The disadvantages of such designs include:

- complexity in the construction of the structure;

- duration of work;

- high price of materials.

Kuznetsov's furnace is an effective heating system. You can erect structures with a hob, dryer for vegetables, fruits, berries and mushrooms, as well as a bread machine. Furnishing the furnace is best entrusted to a professional. If this is not possible, then you can erect the structure yourself, using the schemes given in this article for this.