In order to ensure safe operation of the solid fuel boiler for a long time, certain rules must be followed during its installation. Today, the installation of a heating system in the house is becoming a prerequisite for a comfortable stay. This is a rather difficult and responsible matter. Therefore, during the installation of a heating system that runs on solid fuel with your own hands, you just need to understand the course and rules of its installation, so that in the future there will be no problems.

Basic rules for installing a solid fuel boiler

The first and important thing is the boiler room. It should be well ventilated to provide the combustion of the boiler furnace with the necessary amount of oxygen. The thickness of the concrete base of the boiler room floor must be at least 5 cm. When installing the solid fuel boiler, the location of the boiler room and the quality of the equipment must be taken into account. This is of utmost importance. Real branded equipment is quite expensive, so it is advisable that professionals install it. If you still decide to do the installation yourself, with your own hands, then the following is a list of the necessary installation work:

The first and important thing is the boiler room. It should be well ventilated to provide the combustion of the boiler furnace with the necessary amount of oxygen. The thickness of the concrete base of the boiler room floor must be at least 5 cm. When installing the solid fuel boiler, the location of the boiler room and the quality of the equipment must be taken into account. This is of utmost importance. Real branded equipment is quite expensive, so it is advisable that professionals install it. If you still decide to do the installation yourself, with your own hands, then the following is a list of the necessary installation work:

- install the boiler in the boiler room;

- lay pipes;

- make a strapping;

- to run.

As for the standards, in order to ensure the safe functioning of the heating system with a solid fuel boiler, it is necessary to connect the system taking into account each item. So, the installation standards are as follows:

- the boiler room should be spacious; its area is more than 7 sq.m .;

- it is necessary to equip the boiler room with air flow, calculate the diameter of the ventilation channel at the rate of 80 mm. per 1 kW of solid fuel boiler power;

- the equipment must be separated from the walls of the boiler room at a distance of at least 50 cm;

- floor covering is mandatory from materials that do not support combustion;

- the diameter of the chimney must be calculated based on the exhaust for the smoke of the boiler itself;

- the calculation scheme of some indicators is contained in the documents for the heating unit;

- water and electricity should be connected in accordance with fire safety standards and the scheme specified in the documents;

- remember that the heat transfer of the heating system depends on the correct installation of the chimney.

What is necessary for a quality installation

For high-quality installation of a solid fuel unit, it is necessary to calculate the parameters of the boiler room, carry out piping, and consider the slopes. To do this, you will need special equipment, a list of which must be made in advance, based on the instructions for the heating system.

Solid fuel boiler installation

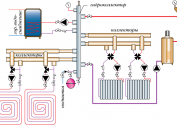

Below is a diagram of the installation of a solid fuel heating boiler:

Below is a diagram of the installation of a solid fuel heating boiler:

- prepare the boiler room and all the premises of the house for installation, pour a concrete platform under the boiler;

- install the boiler and mount the system;

- conduct strapping, that is, connect water pipes, return pipes and additional equipment;

- equip the chimney;

- start the system.

If you are installing a solid fuel boiler yourself, consider the following:

- heat transfer of the heating system to a greater extent depends on the type and quality of fuel, the completeness and time of its combustion;

- the optimal location, in accordance with the direction of the wind, as well as the length of the chimney itself, affects the quality of the equipment;

- thermal insulation of the house, an important factor that affects the life of the unit, heat preservation will protect the heating system from unnecessary restarts;

- it is necessary to correctly calculate the diameter of the heating pipes.

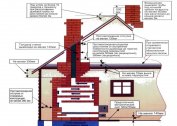

Necessary requirements for installing the chimney:

- when installing the chimney with your own hands, you should pay attention to the absence of turns or round off the rotation angles;

- treat all joints with sealant or special tape;

- calculate the strength of the design of the chimney, taking into account the weight of the pipe and stock;

- check the coincidence of the diameter of the chimney pipes and the exit from the boiler.

The scheme of post-installation work:

The scheme of post-installation work:

- check all pipes and connections for leaks, tighten if necessary;

- check the heating hydraulic system, rinse it thoroughly;

- If there is an automatic security system, configure it and start it.

The scheme of starting a solid fuel heating unit for the first time:

- carefully read the instructions, deal with the control system of the heating system;

- fill the system with water;

- to release the boiler room from unnecessary things and garbage;

- close all doors of the boiler;

- All detected malfunctions, after a trial run, should be eliminated only after the system has cooled down.

These are just some of the main points in installing a solid fuel heating system. Naturally, the best choice is to entrust such a complex and responsible work of an organization specializing in the installation of this type of equipment. This will give you guarantees in the correct installation and start-up of the heating system. Qualitatively installed equipment for heating will certainly provide you with a comfortable stay. Do not forget also that much also depends on the choice of the brand of the boiler. Pay attention to power and battery life. These two main qualities of heating units will provide comfort in your home. And most importantly, the high power of the boiler is not a fact of increased fuel consumption and high costs of its operation.