The heat loss of buildings, in most cases, is due to the cooling of the walls. This problem is especially relevant for suburban or private houses with a separate location. Even high-quality metal-plastic windows cannot prevent a drop in temperature. Therefore, the only solution to this problem is wall insulation from the outside.

Why is it important to insulate the walls

The main task of the external insulation of the house is to minimize heat loss and, as a result, reduce heating costs in the winter.

The main task of the external insulation of the house is to minimize heat loss and, as a result, reduce heating costs in the winter.

Thermal insulation provides:

- reducing the risk of deformation of external walls under the influence of temperatures;

- comfortable living conditions not only in winter and summer;

- elimination of defects that arose during the operation of the building;

- saving building materials at the stage of building a house: it is enough to make the wall thickness such that it provides only the reliability of the floors.

Types of materials and their selection

Most often, types of facade materials are used:

- polystyrene foam;

- polyurethane foam;

- thermal panels;

- extruded polystyrene foam;

- mineral wool.

Expanded polystyrene

Inexpensive material for wall insulation, has a low weight, is easy to install. The cellular structure provides its low thermal conductivity - up to 0.043 W / (m · K).

Inexpensive material for wall insulation, has a low weight, is easy to install. The cellular structure provides its low thermal conductivity - up to 0.043 W / (m · K).

Disadvantages:

- low vapor permeability;

- during combustion, the material releases toxic substances that are hazardous to health. There are types with a fire safety class G1, G2: during the manufacture of stoves, the manufacturer adds flame retardants that slow down combustion;

- low strength and fragility.

It is undesirable to use the material for aerated concrete houses: this can lead to absorption of moisture by blocks and a decrease in their thermal insulation properties. Polyfoam is suitable for walls made of concrete.

Polyurethane foam

Liquid material, has high adhesion. Warming is applied in a continuous layer, without seams, so the appearance of cold bridges on the surface of the wall is excluded. The material does not absorb moisture and has a low coefficient of thermal conductivity - up to 0.030 W / (m · K).

Liquid material, has high adhesion. Warming is applied in a continuous layer, without seams, so the appearance of cold bridges on the surface of the wall is excluded. The material does not absorb moisture and has a low coefficient of thermal conductivity - up to 0.030 W / (m · K).

Disadvantages:

- installation requires skills and the availability of special equipment;

- lack of vapor permeability;

- high cost in comparison with other heat-insulating materials.

The use of polyurethane foam is suitable for ventilated facades or in frame houses. The material is not used for thermal insulation of wooden and aerated concrete houses.

Thermopanels

They are a system of a moisture-resistant layer, insulation (polystyrene foam or polyurethane foam) and a protective layer (porcelain, ceramic, clinker tiles). Available in two forms: with a surface imitating masonry or for painting. The product has a long service life - up to 15 years.

They are a system of a moisture-resistant layer, insulation (polystyrene foam or polyurethane foam) and a protective layer (porcelain, ceramic, clinker tiles). Available in two forms: with a surface imitating masonry or for painting. The product has a long service life - up to 15 years.

Disadvantages:

- chipping seams, cracking paint;

- possible deformation of the panels during installation;

- high price.

Extruded Styrofoam

Closed cell material is obtained by high temperature foam treatment. It has a low coefficient of thermal conductivity up to 0, 034 W / (m · K), high compressive strength.

Disadvantages:

- the inability to use a “wet” facade in insulation systems, since the smooth surface of the plates has low adhesion.

Mineral wool

Depending on the composition, the material may be:

Depending on the composition, the material may be:

- glass wool - glass, quartz sand, limestone and dolomite are used in the manufacturing process. Fibers are obtained by melting the mixture and blowing with steam. It is an environmentally friendly, non-combustible material with low density and thermal conductivity. The disadvantage of glass wool is its hygroscopicity;

- basalt - produced by crushing and heating rocks of volcanic origin and basalt. Non-combustible cotton wool, has low thermal conductivity. When heated to a temperature of more than 600 ° C, the fibers may melt and stick together.

For the insulation of building facades, material is used that is produced in plates, the density of which for ventilated facades should be from 45 to 100 kg / m3, for plaster - 145-165 kg / m3.

The material is suitable for insulating “wet” and ventilated facades.

The main criterion for choosing a heat-insulating layer is the ability of the walls to pass steam: if the facade is made of vapor-proof material, and the insulation is vapor-permeable, then the moisture coming from the room will accumulate inside the walls and destroy them.

Mounting Features

An obligatory stage of home insulation is surface preparation: removing the old layer of wall coverings, leveling and applying a primer mixture.

An obligatory stage of home insulation is surface preparation: removing the old layer of wall coverings, leveling and applying a primer mixture.

Polyfoam and extruded polystyrene foam:

- on the lower horizontal line of the wall, install a metal profile that ensures alignment of the first row of plates;

- apply glue pointwise on the sheet (for mounting on an uneven wall) or on the entire plane of the plate, attach and press the foam onto the wall. Further work can be carried out only after complete solidification of the solution;

- the installation of the second layer is carried out with the displacement of the new plates relatively laid, like brickwork. Fix polyfoam with dish-shaped expansion bolt shields on corners of a plate and in the center;

- in places where the material adjoins the windows and doorways, install a special profile with a self-adhesive strip on the frame, use a perforated profile to trim the outer corners;

- the surface lined with plates, cover with a reinforcing polymer mesh, fixing it with glue. At the joints of the plates, overlap the mesh to 100 mm.

Thermopanels:

- installation does not require a zero mark, since during the production process plastic guides are fixed in the product. Installation begins with corner elements;

- a hole is drilled into the base of the wall through the panel and a plastic dowel is installed, after which a screw is screwed;

- in the case of installing the product on the crate, the space between the wall and the insulation is filled with foam;

- the joints of the panels are treated with sealant, the seams are overwritten (work is performed only at air temperatures above zero).

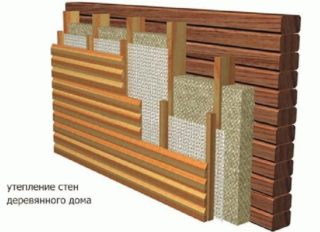

Mineral wool insulation:

The method requires the arrangement of a frame system of such a width that the cotton wool fits tightly between structural elements. Plates are installed with a soft layer to the wall and fixed with dish-shaped dowels or adhesive solution.

The method requires the arrangement of a frame system of such a width that the cotton wool fits tightly between structural elements. Plates are installed with a soft layer to the wall and fixed with dish-shaped dowels or adhesive solution.

Polyurethane insulation:

The solution under high pressure is fed to the walls using special equipment. Being in the liquid phase, the material fills all the cracks on the surface. After polymerization, the foam is cut off and the wall is plastered or covered with a facing brick, siding.

Maintaining a comfortable temperature inside the house also depends on the thickness of the outer insulation layer. Brick or concrete walls are subject to rapid heating and cooling, so more heat-insulating material will be needed. Also pay attention to the supporting structures - the thinner they are, the greater the thickness of the insulation should be.