The fastest affordable way to solve the housing problem is to build a frame house. However, to ensure a comfortable stay, quality insulation is necessary. First of all, the insulation is mounted in the hollow frame of the structure, the roof is insulated. Then the floor is lined with a heat insulator, which in frame structures is built in parallel with the construction of the foundation.

Foundation preparation

How the insulation of the surface will be carried out depends on the type of foundation, which can be tape, columnar, pile-grillage. The base is lined on the ground or using a log, after which there is a layer of rough flooring, finishing. For work, you will need a wooden beam, a processed board or sheets of moisture-proof plywood. To keep the surface warm, it is layered, using insulation to protect it from the cold.

How the insulation of the surface will be carried out depends on the type of foundation, which can be tape, columnar, pile-grillage. The base is lined on the ground or using a log, after which there is a layer of rough flooring, finishing. For work, you will need a wooden beam, a processed board or sheets of moisture-proof plywood. To keep the surface warm, it is layered, using insulation to protect it from the cold.

Particular attention is paid to the foundation:

- First, it is checked for the absence of height differences, the equality of diagonals.

- Anchor bolts are installed around the perimeter of the structure, to which the beds will later be fixed.

- Inside the perimeter, it is necessary to install concrete supports with a step of 2-3 m, then - support bars.

- The foundation is waterproofed with a gluing, coating method, simultaneously making pockets for beams.

Insulation materials

Styrofoam

An excellent option is a hollow polystyrene foam, which is ideal if the base is sheathed with a lag. The material is characterized by heat capacity, light weight, sound, vibration isolation. It has a high density, so there is no convection in it. Hollow foam reflects infrared radiation by 90%, when it is laid there is no need for shielding.

An excellent option is a hollow polystyrene foam, which is ideal if the base is sheathed with a lag. The material is characterized by heat capacity, light weight, sound, vibration isolation. It has a high density, so there is no convection in it. Hollow foam reflects infrared radiation by 90%, when it is laid there is no need for shielding.

Polystyrene lining is an environmentally friendly, cheap, option of protection from the cold. It is safe, environmentally friendly, creates a favorable indoor climate, work takes a minimum of time, money.

The only drawback is that the insulation is unstable to external influences, it is destroyed when exposed to direct sunlight.

Wool Fiber Material

Glass wool - A strong, elastic insulation, but you need to work with it only in protective clothing, a mask, gloves. Thin fibers, getting on the skin, in the respiratory tract cause irritation. The hollow material has thermal conductivity, can withstand temperatures from -60 ° C to + 500 ° C.

Glass wool - A strong, elastic insulation, but you need to work with it only in protective clothing, a mask, gloves. Thin fibers, getting on the skin, in the respiratory tract cause irritation. The hollow material has thermal conductivity, can withstand temperatures from -60 ° C to + 500 ° C.

Slaggymade from blast furnace slag is ideal for rooms with normal and low humidity. Where wet, it should not be laid. Hollow wool slag absorb water well, suitable for warming various surfaces, walls, attics. It has a specific heat, low cost, maximum ease of installation.

Stone wool available in mats, rolls. Hollow mineral material is heat-resistant, fireproof. It will be good protection against vibration and noise, easy to install, affordable.

Roll polymer materials

To protect the building from the cold, roll polymer material is also used. Warming is carried out using hollow isolon, penofol.

To protect the building from the cold, roll polymer material is also used. Warming is carried out using hollow isolon, penofol.

Isolon is obtained by foaming polyethylene. It is characterized by a low degree of water absorption, low weight, and can not be deformed. Hollow Isolon is durable, does not break, withstands high temperatures. It is environmentally friendly, safe, decomposes on burning, without releasing toxins. The material has noise, vibration isolation, chemical resistance. Most often, foil hollow isolon with good heat-reflecting abilities is used for insulation.

The frame house is sheathed with penofol, which is a foamed hollow polyethylene foil on one or both sides, sometimes with a one-sided adhesive coating. Hollow material has heat capacity, sound insulation, water-repellent properties, and allows air to pass through. The thickness of penofol varies from 3 to 10 mm, insulation is carried out at a temperature of + 70 ° C to -40 ° C.

The easiest way to use a hollow material with a self-adhesive layer with a heat reflectance of about 97%. It is enough to remove the protective film, apply it on a plane, press.

Roll hollow material is first cut, if there is no self-adhesive side, it is glued, for example, neoprene. Joints are glued with foil tape, reducing heat loss. Roll hollow material is suitable for organizing water or electric underfloor heating systems.

Warm floor

Modern housing methods offer efficient heating methods. Warming is carried out by installing an electric or water floor heating. In the first case, an electric cable is laid under the flooring, in the second - pipes in which water circulates.

Electric cable underfloor heating

A set of equipment for organizing insulation consists of a cable, corrugated tube, temperature regulator, sensor. Additionally, you need insulation, foam. Initially, the electric cable is cut into sections, placed in the thickness of concrete, a sensor that controls the temperature is also placed there. The thickness of concrete depends on the finish. 3-5 cm are enough for tiles, less for laminate and linoleum.

A set of equipment for organizing insulation consists of a cable, corrugated tube, temperature regulator, sensor. Additionally, you need insulation, foam. Initially, the electric cable is cut into sections, placed in the thickness of concrete, a sensor that controls the temperature is also placed there. The thickness of concrete depends on the finish. 3-5 cm are enough for tiles, less for laminate and linoleum.

The ends of the cable, the sensor wiring are connected to the thermostat. After a beep, a connection or disconnection from the power supply occurs, which allows you to save heating. The duration of the heating-cooling cycle depends on the thermal insulation of the room, the power of the heating system. The installation process looks like this:

- They mark the place on the thermostat, stepping back from the horizontal of the base 1.3-1.5 m, then make a stroba in the wall where the temperature sensor and wires for supplying current are placed.

- The concrete base is insulated, which will save up to 50% of the heat.

- Perform a concrete screed, lay the tape with fixation with dowels so that the insulation and cable do not intersect.

- Lay the heating cable, fixing it every 0.25 m with plastic clamps.

- The temperature sensor is placed in a corrugated tube, fixed in half a meter from the wall so that it is in an open loop between the turns of the wiring.

- They lay an electric cable, arrange a concrete screed up to 5 cm thick, lay linoleum, laminate, tile.

- Set the temperature controller, leave the surface for a month to dry.

Water floor heating

It is laid on the flooring from expanded polystyrene foam, using heat-distributing aluminum plates.

It is laid on the flooring from expanded polystyrene foam, using heat-distributing aluminum plates.

A layer of sheet insulation with a thickness of up to 40 mm is laid out on the flooring, while a groove is selected along the laying contour along which heat distribution plates are mounted. The recesses of the plates are filled with a pipeline, and a prefabricated screed made of hypo-fiber plates is mounted on top. Then lay a layer of cardboard or foamed hollow polyethylene, finish coating, parquet, tile, laminate, other material.

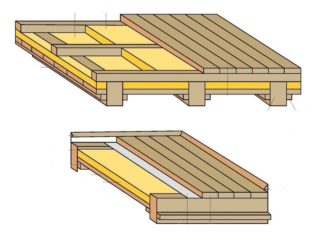

The device and thermal insulation lag

Installation of the lag is carried out after the draft floor with waterproofing is ready.

Installation of the lag is carried out after the draft floor with waterproofing is ready.

For logs you need wooden bars, impregnated with fire-resistant, moisture-resistant impregnations, which are fixed on a plane. At the same time, a step of 0.9-1 m is observed, they make sure that the lag size is 50-150 mm or more. It all depends on which insulation is selected, and its width is oriented.

It is important when arranging the lag to leave a gap of a few centimeters between the structure and the wall. Thereafter, a hollow insulation will be placed that protects against drafts.

To fix the lag, self-tapping screws are suitable, which are driven deep into the wood.Then they take a hollow insulation, tightly insert it into the gaps between the bars tightly.

They make sure that the hollow insulation does not protrude above the lag level, fills the gaps.

Arrangement of logs is continued, mounting on top of the floorboard insulation. They are laid out, fixed with nails, screws. The final finish of the lag is wood paneling, moisture-proof plywood, laminate, cork, whatever.

For cheaper lining, a fiberboard layer is used on top of the floorboard, then linoleum.

Ground insulation

Work is carried out only in the warm season. First, make a screed of cement and sand, after which it is sheathed, trimmed. Work execution order:

Work is carried out only in the warm season. First, make a screed of cement and sand, after which it is sheathed, trimmed. Work execution order:

First, the soil is compacted, after which a film waterproofing is lined with an overlap on the wall, to a height of 0.25 m. After completion of work, excess film is cut off;

They install insulation, for which expanded clay, a mineral clay material of high heat capacity, is ideally suited. The expanded clay layer with a thickness of 0.1 m in its ability to retain heat is similar to 1 m of masonry. To use this quality, the insulation is laid strictly according to technology;

Mineral granular expanded clay with a diameter of 10 cm is suitable, additives of other fractions are mixed in, which provides high-quality insulation that does not shrink;

The line attached to the beacons will help to level the layer, to find out the evenness of the expanded clay filling;

Then the plane is poured with sand-cement mortar for screed, the layer should be at least 5 cm. Otherwise, it will not withstand the weight of furniture, household appliances, it will begin to sag;

Sometimes, for ease of pouring, hollow granules are mixed with sand and cement, and the surface is poured. Finished a month after pouring. This is enough for the mineral insulation to freeze and become durable.

Instead of expanded clay, you can use extruded hollow polystyrene foam in the plates. In this case, the middle layer of the screed is reinforced with a grid of rods with a diameter of 8 mm and above. The screed is also carried out in a dry way, lining moisture-proof plywood, under which the insulation is poured.

Carefully waterproof the corners of the room, the area of the baseboard. In this case, the frame house will be protected from drafts as much as possible.

Filling a rough coating

After the surface is prepared, cleaned of debris, organize a rough floor. They take wooden blocks, self-tapping screws, mount the crate with a step of 0.4-0.5 m, and stuff boards with a width of 200 mm from above.

Before laying, the wood is treated with antiseptics, fire-resistant solutions. This will eliminate mold, make the design durable.

Take membrane waterproofing, line the surface. It will become an obstacle to moisture, which will go down.

After laying the membrane with an overlap of 10-15 cm, the joints are carefully glued with moisture-resistant tape.