To equip the floor in the room is one of the conditions for a comfortable stay. You can carry out insulation in several ways, each of which has its positive and negative sides. It is important to choose the right insulation, which will provide the optimal microclimate of the room in the most severe frosts.

How to prepare a concrete base for insulation

There are several ways that will provide high-quality insulation, but first you need to prepare the base of the room:

There are several ways that will provide high-quality insulation, but first you need to prepare the base of the room:

The old cladding is dismantled, the rough coating is right up to the concrete slab. Concrete flooring is carefully examined for cracks, chips, potholes. If there are defects, they are cleaned of debris, expanding with a puncher, a grinder, along the way, sticking out reinforcement, influxes, so that the concrete floor is even. Prepared concrete rough flooring is filled with mortar, leveled.

To get a concrete strong floor with increased adhesion, it is treated with special impregnation.

Before warming, it is necessary to send the concrete flooring with a film or a waterproofing membrane. Additionally, the walls are protected by waterproofing, starting the film on them to a height of about 15-20 cm. After the completion of the waterproofing, it is possible to lay the insulation and carry out further cladding.

Materials for thermal insulation

How to equip a room, what material to choose? First of all, pay attention to such indicators:

- Density, structure - the more porous the hollow material, the lower its density;

- Thermal conductivity - the higher the indicator, the worse the hollow insulation retains heat;

- Moisture permeability - whether a hollow insulation is able to absorb moisture from other coatings, the environment. To keep the room warm, it is desirable that the coefficient be as low as possible;

- Strength - determines whether the hollow insulation is able to withstand loads, deformation. To keep the concrete floor warm, you should choose a high-strength material;

- Durability - an indicator by which it is determined whether a hollow insulation is able to maintain quality during prolonged use;

- Moisture resistance - it is desirable that it be as high as possible;

- Environmental friendliness is an important indicator that ensures comfortable living. Hollow material should not be poisonous, toxins should be emitted during combustion.

Mineral, basalt or fiberglass wool

Mineral wool is a popular hollow insulation material, cheap and heat-resistant. It is available in rolls and mats, can be of organic and inorganic origin.

Mineral wool is a popular hollow insulation material, cheap and heat-resistant. It is available in rolls and mats, can be of organic and inorganic origin.

Minvata happens:

- Slag, with the addition of blast furnace slag. It has high thermal conductivity, but is unstable to vibration, moisture, decomposes with the release of acid;

- Basalt - hollow insulation with the addition of dolomites, limestones, is produced in different densities. It is resistant to moisture, noise, vibration, high temperatures. Now on sale there is cotton wool on a substrate of foil, fiberglass, stitched with fiberglass or wire. It is characterized by increased strength, withstands strong pressure, compression;

- Fiberglass - cheap hollow material with low thermal conductivity. It has a high noise, vibration isolation, compresses well, but is deformed under loads, pressure.

Styrofoam plates, polystyrene

Polyfoam is a hollow material that perfectly retains heat, durable, affordable. This is a popular moisture-proof insulation, which is universally lined with flooring. Hollow material is used for insulation of basements, it is easy to equip with it a reliable, durable concrete floor with heating.

Polyfoam is a hollow material that perfectly retains heat, durable, affordable. This is a popular moisture-proof insulation, which is universally lined with flooring. Hollow material is used for insulation of basements, it is easy to equip with it a reliable, durable concrete floor with heating.

A type of polystyrene is extruded polystyrene, in fact, an analog of polystyrene, but with improved properties. The hollow material is more dense in structure, has a high resistance to deformation.

Polyurethane foam, penoizol

Polyurethane foam is a sprayed insulation of a new generation. It and its hollow analogue penoizol are resistant to moisture, temperature differences, mechanical damage. Hollow porous material is economical, safe for health, easily sprayed with a special installation up to 10 cm thick. It is easily applied to a concrete standard floor, other surfaces, forming a smooth plane without joints, irregularities.

Polyurethane foam is a sprayed insulation of a new generation. It and its hollow analogue penoizol are resistant to moisture, temperature differences, mechanical damage. Hollow porous material is economical, safe for health, easily sprayed with a special installation up to 10 cm thick. It is easily applied to a concrete standard floor, other surfaces, forming a smooth plane without joints, irregularities.

The only drawback of polyurethane foam, penoizol is the high cost of the technology, because special equipment is necessary for spraying.

Insulation technology

Layered cake

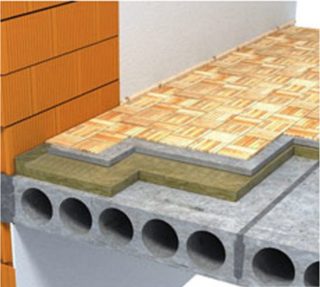

Insulation on logs is one of the most common options to equip a concrete floor. The order of execution is as follows.

Insulation on logs is one of the most common options to equip a concrete floor. The order of execution is as follows.

On a concrete floor covered with moisture protection, a hollow crate of wooden bars is installed. Usually use standard bars with a cross section of 5050 mm. For maximum protection against moisture when installing a hollow crate, strips of roofing material are laid under them.

Logs are mounted on the bars - slats or thick boards made of wood. Each of them is covered with a special impregnation that protects from fire, fungus, mold. The thickness of the bars for the log should be slightly larger than the width of the insulation. It is important that after installation the hollow insulation does not protrude above the lag level.

Logs must be leveled using a level, plastic or wooden wedges. The structure is fixed on the floor by through drilling, driving in anchors.

Then it is necessary to lay the insulation, mount the draft floor.

The selected insulation material is placed in the voids between the lags for waterproofing. Having laid a heater, a layer of a vapor barrier membrane is lined on top. This is especially important if a material that absorbs moisture quickly is selected for insulation.

A draft floor is attached to the logs on the vapor barrier layer. Particleboard, thick plywood, OSB, unedged board are ideal for this.

When the concrete flooring, insulation is over, proceed to the final finish.

If it is decided to sheathe the concrete floor with tiles, it is worth mounting the base on which a layer of plywood is laid, then a draft floor from the boards.

Concrete "heat-insulated floor"

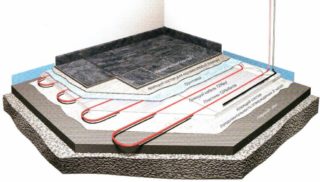

Electric. Installation is carried out directly on the thermal insulation layer. The simplest technology is electric cable flooring.

Electric. Installation is carried out directly on the thermal insulation layer. The simplest technology is electric cable flooring.

It is a mesh mat of small thickness with a heating cable with a cross section of about 2.8 mm. The installation process consists in laying them on a concrete layer and fixing them securely. Thermal insulation by this technology is universal, suitable for installation under a laminate, linoleum, and tile. If electric heating mats are placed under linoleum, laminate, carpet, it is not necessary to fill in a thick layer of screed, 3-4 cm is enough. Electric heating mats are not placed in places where plumbing and furniture will subsequently be installed. When installing cables and wires, it’s worth retreating from the walls by 5-7 cm. Also, communications should not be laid near sources of heating.

Water. It is mounted in private houses, multi-story buildings on the ground floors. If the system will leak after installation on the upper floors, there is a possibility of flooding the neighbors from below. Initially, waterproofing, insulation of the base is carried out, for which polyurethane, foam plates or penofol are used. Material for insulation must be placed at a distance of 5 mm from the wall, otherwise it can be deformed. For laying, you will need metal-plastic or polypropylene pipes, which are laid out on the insulation layer, fixed with special brackets, clips or brackets.

Infrared. The floor is a two-layer film with a thickness of 0.5 mm with heating carbon elements.It is attractive in that, unlike other systems, it allows you to save the configuration, height of the room without changes. This is the most energy-saving option for insulation, which saves up to 60% of electricity. The film coating with heating elements can be installed vertically, horizontally, obliquely by "dry installation". The installation is simple: the strip of film is spread without regard to the areas where the furniture will stand. After that, you can immediately line the floor without prior cement screed. After that, the ends of the supply and return pipelines are led out, connected to the collector, and at the very end to the water supply. Then it is necessary to fill in the concrete layer of the screed, filling it with water before filling the pipe. When the work is finished, it is worth letting the surface dry, after which you can line the flooring and use heating.

Which heating option to choose depends on the characteristics of the premises, the financial capabilities of the owner of the house. It is important to carry out work efficiently, using technology. If you have tools, some experience in this matter, you can carry out the work yourself. Otherwise, you should trust the professionals, otherwise the rework will be very expensive.