Despite the possibility of installing gas heating - wood heating is still relevant. It is done in the absence of gas pipelines and in the presence of cheap wood energy sources. But how to organize the wood-burning heating of a private house with your own hands on a professional level? Description of boilers, schemes and reviews will help solve this problem.

How to make wood heating

Modern wood heating of a country house differs significantly from old schemes. For this, practically no large brick stoves are used. They performed the function of a heat exchanger - when heated, their surface transferred heat to the air in the room. However, they were replaced by modern wood heating to the cottage with the installation of boilers, piping, radiators and batteries.

A feature is the ability to use several types of structures for burning wood - stoves, fireplaces or boilers. It all depends on the area of the house, the possibility of placing heating appliances and the budget of the whole event. In order to make wood-burning heating of a private house with your own hands, you will need to consider the following factors:

- Required thermal power of the system. Depends on the degree of thermal insulation of the house, its volume and climatic features of the region;

- The need for a separate boiler room. It is important to know that a wood-burning boiler for heating a house must be installed in a separate room, to which special requirements are imposed;

- Place for storing firewood. According to safety rules, it is forbidden to store solid fuel in the same room with the boiler.

What is the best choice - a wood-burning heating boiler for giving, a fireplace or stove? It all depends on the parameters of the building and financial capabilities. The best option is to make water heating, in which the boiler will perform the function of heating the water. For a more detailed analysis, you should weigh the pros and cons for each type of heater.

Additionally, with heating, you can make a hot water system at home. For this, it is necessary to install a double-circuit wood heating boiler.

Schemes of wood heating at home

The key point in the design of wood heating is the choice of scheme. It depends on her whether a wood-fired heating boiler will be installed with her own hands or whether the stove or fireplace will perform its functions. To determine the best option, it is necessary to take into account all possible factors.

First of all, the area of the building and the number of rooms are taken into account. Most often, wood-fired heating stoves for summer cottages are installed if there are a maximum of two rooms. In this case, you do not need to make a water heating system.

Consider the main factors affecting the choice of type of heating:

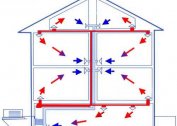

- Water. It consists of a boiler (stove, fireplace) connected to the pipeline. The transfer of thermal energy occurs due to installed radiators. The best option for a house with an area of 80 m²;

- Stove. To heat the air in the room, wood-burning stoves are used. They are characterized by low efficiency, small heating area. However, their arrangement requires the least effort. An exception is chamotte brick structures. This type is used for heating houses with an area of less than 60 m²;

- Mantelpiece. An analogue of stove heating.The difference is pumped in the size of the combustion chamber - by the fireplace it is much larger. In addition, heating a private house with a wood boiler sometimes implies the presence of a hob in the structure.

As you can see, the choice of option directly depends on the area of the house. It should be borne in mind that the scheme of wood heating can be upgraded. It is enough to install a heat exchanger in the oven to make it possible to make a full-fledged water heat supply.

But the most common option is to install a wood boiler for heating a house. It is much more practical and easier to use than a fireplace or stove.

For the normal operation of the wood heating of a country house, it is necessary to think over a chimney system in advance. The optimum pipe diameter and its height are taken into account.

Overview of solid fuel boilers

The determining component for water-based wood heating is the boiler. It is on its characteristics that the parameters of all wood heating in the country house or house will largely depend.

Before drawing up the heating circuit, it is necessary to determine the operational and structural characteristics of the boiler:

- Type of construction - classic or long burning. The cost of the latter is 50-60% more, but at the same time fuel consumption is significantly reduced, and the level of autonomy in work is also increased.

- Rated power. To do this, it is necessary to calculate the heat loss in the house, which should be compensated by wood heating for a summer residence.

- Design Features - the thickness of the metal, its composition, shape and volume of the heat exchanger.

An important factor is the cost of heating equipment. That is why, in frequent cases, they make home-made wood-fired heating boilers adapted for a particular system.

For the construction of a full-fledged wood-burning heating furnace for a summer residence, it will be necessary to fill in a separate foundation, not connected with the main one. This applies only to those cases where the mass of the future design exceeds 600 kg.

Classic wood boilers

Often, reviews of a wood heating boiler indicate their low efficiency in operation. Often this is due to the wrong choice of model and non-compliance with the rules of installation and operation. This is especially true of classic wood-fired heating boilers for summer cottages.

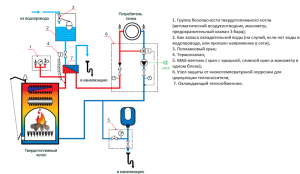

The principle of its operation is based on the transfer of thermal energy from burning wood to water in a heat exchanger. For this, the following elements are provided in the design:

- Firebox. Firewood is laid in it for further combustion. Its volume determines the power of a do-it-yourself wood-burning heating boiler. The same applies to factory models;

- Ashpit. It has two functions. The most important of these is the air supply to maintain the combustion process. It is she who creates the traction necessary for the normal operation of a home-made wood heating boiler. The second task is to collect ash. Otherwise, it will clog the furnace capacity;

- Chimney. It is necessary for the removal of carbon monoxide, with its help air draft is formed. It is important to choose the correct diameter of the chimney, since without this, the wood-burning heating of a private house with your own hands will decrease efficiency and efficiency;

- Heat exchanger. In classic models, it is an area located between the inner and outer shell of the boiler. It is filled with water from the system. To connect to the heat supply of the house, pipes are provided in the design.

The main problem in heating a private house with a wood boiler is the inability to affect the power of the equipment. To do this, you can only limit the flow of air through the ash pan, thereby reducing the amount of circulated oxygen. At the same time, the level of combustion of firewood will affect the power to a greater extent.

Before purchasing a boiler, it is necessary to find out the maximum length of firewood that can be loaded into the combustion chamber.

Long burning wood boilers

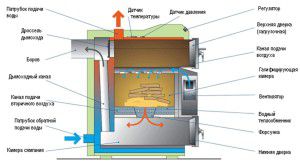

An alternative to classic boilers are pyrolysis models. They also have the name of long-burning boilers. Their principle of operation differs from those described above and is based on the release of a mass of heat not from the combustion of firewood, but from the gas generated during their decay.

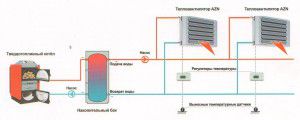

There is no ash pan in the design. Its function is performed by a special air duct, which in most cases has a fan. After loading the firewood into the primary chamber, they are ignited. Due to the low oxygen content in this area, the wood does not burn, but smolders, resulting in the formation of wood gas. It moves to the afterburning zone, where it ignites. A heat exchanger is located in the same part of a double-circuit wood heating boiler.

What is the difference between wood-burning stoves for a house with water heating from the above design? The main advantage is a long time of fuel combustion. In factory models, one load is enough for 4-6 hours of boiler operation. In addition to these advantages, the following can be distinguished:

- Possibility of power regulation. In wood-burning stoves, this happens due to the opening (closing) of the ash pan door. In pyrolysis models, the degree of water heating is controlled by the air supply rate;

- Realization of a low-temperature operating mode of heating. The water heating level in classic models can reach + 95 ° С. This mode is currently considered ineffective. With normal thermal insulation of the house, the optimal regime should be 65/50. At the same time, energy consumption will decrease;

- Practical complete burnout. Unlike wood-burning stoves for a house with water heating, the intensity of flue pollution in pyrolysis boilers is much lower.

The main disadvantage of long burning boilers is the high cost. However, if you calculate the operating costs, fuel consumption - the economic efficiency of their installation will be obvious.

For the normal operation of the wood heat supply of a country house with pyrolysis boilers, a complete set with an automatic fan intensity control is necessary. It can be connected to external temperature sensors.

Rules for organizing a boiler room for wood heating

The professional organization of wood heating of a private house independently implies the arrangement of a boiler room. This should be a separate room in which the boiler and means of regulating its operation are located.

If the wood heating to the country is done according to the gravitational scheme, the boiler should be located at the lowest point in the system. For forced heat supply there are no such requirements. You should also prepare the room in which the heating equipment will be mounted. It must meet the following requirements:

- Ceiling height - at least 2.5 m;

- Useful area - from 6 m². At the same time, its minimum volume should be 15 m³;

- Forced ventilation Air exchange rate - three times the volume during the operation of the wood boiler for heating the house;

- Parameters of the chimney channel. The minimum height is 4 m. The diameter depends on the connected nozzle of the boiler, but not less than 100 mm;

- For carrying out preventive and repair work, it is necessary to provide free access to all sides of the wood-burning heating boiler for a summer residence;

- Lighting should be combined - natural and artificial.

An important point is to ensure fire safety. To do this, use only non-combustible materials for decoration. If electric elements are used in the heating of a private house with the help of a wood boiler, the power line should be connected.Installation of the ground loop is carried out only at the request of the manufacturer.

One of the problems in the operation of a wood heating stove is the likelihood of back draft. To minimize this effect, it is recommended that a special design be installed in the chimney.

Making a wood-fired boiler with your own hands

Is it difficult to make a wood-fired boiler for the house with your own hands? The main condition for this design is the thickness and grade of steel used. In factory models, the outer casing is made of heat-resistant steel with a thickness of 1.5 mm or more. For a heat exchanger, these parameters should be larger - from 2 mm.

The best option is to create a welded structure, which in shape will be similar to the factory models. However, if you calculate the complexity of the work and the cost of materials - the difference between the purchase and self-production will be low. Therefore, as an alternative to wood-burning stoves for a house with water heat supply, simple steel barrels are often used. The main condition is the thickness of their wall - from 1.5 mm.

For production, a capacity of about 200 liters is required. It is cut along and a partition is installed inside. Its length should be less than the length of the barrel. This is necessary for the installation of grates.

Then, holes for mounting doors are cut out on the front side. They should be selected in advance so as not to be mistaken with the sizes. To remove carbon monoxide from the reverse side of the structure, a chimney pipe crashes. Its diameter can be from 50 to 100mm.

However, judging by the reviews of such a wood heating boiler, the following disadvantages can be noted:

- Low rate of efficiency;

- Heating the case, which can cause burns when touched;

- Short service life.

Similar designs are used for heating small utility rooms - a garage, warehouse, etc. For the home, it is best to purchase a factory-quality model. It will comply with modern wood heating schemes.

| Boiler model | power, kWt | Cost, rub. |

| Buderus logano g221 | 20 | 69900 |

| Dakon DOR F 24 | 24 | 60300 |

| Proterm DLO 30 | 24 | 58450 |

Before making a home-made wood boiler for the heating system, it is necessary to calculate the optimal dimensions of the furnace.

Reviews for wood heating

One of the ways to choose a complete set of cottages with a wood stove or boiler is a detailed analysis of reviews. They talk about the advantages and disadvantages of each of these components. However, it is worth knowing that reviews about wood stoves and boilers are almost always subjective:

- Until recently, an old stove stood at our cottage. We already thought to replace it with a boiler, but there was not enough money for this. On the advice of a specialist, a new chimney was installed - a sandwich. And what was the surprise when the craving increased, the consumption of firewood became less. Conclusion - you must first check the remaining components of the furnace, and then think about replacing it;

- After installing a long-burning boiler, the consumption of firewood was significantly reduced. The only thing that was not taken into account is the mandatory warming of the whole house. I had to urgently change the windows to new ones;

- For a summer residence, they decided to make wood heating from the stove. After much thought, we installed a home-made heat exchanger and connected it to the pipes. The result was even better than expected. Now the house heats up much faster.

When organizing wood heating, you need to equip a place for storing fuel. This should be a room with normal room temperature and humidity. Otherwise, raw firewood will have less heat dissipation.

The video tells about the basic rules of wood heating at home: