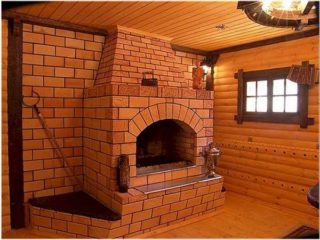

Brick heating stoves are still in demand among the average user living in country houses or in summer cottages. With their help, it is possible to heat not only the residential building itself, but also the bathhouse with the steam room available on the site. Before you build a furnace in your suburban economy, it is useful to familiarize yourself with the known varieties of these structures. In addition, the novice master will have to study the basic masonry schemes of furnace structures and master the methods of working with bricks at home.

Varieties of furnaces

Before you build a stove with your own hands, you will need to familiarize yourself with the existing varieties of units for the home, divided into the following classes:

- cooking constructions;

- cooking stoves;

- stoves designed exclusively for heating.

A home-made cooking stove is the best choice for a summer house or a country site where the owners live in the summer. Most often it is used as an addition to other heating devices in order to save on expensive energy sources. It is equipped with a hob and a special tank used to heat drinking water. Despite the small size of the structure itself, its heat output is enough to warm the structure of an average area.

Cooking and heating stoves allow:

- Cook;

- use as an oven;

- embed a tank for heating water;

- arrange a place for drying products.

Furnaces of this type are in demand in summer cottages during periods of seasonal work.

Purely heating constructions are used only for heating residential and office premises. Often they are equipped with additional tanks, allowing you to install them in the bathhouse as a fireplace or use them to heat water.

When assessing the design of the future furnace, it is necessary to determine in a timely manner its shape and dimensions, depending on the room in which it is planned to be installed.

Choosing a place to install a brick kiln

Before you make the stove yourself, it is important to determine the zone of its permanent location. It can be built anywhere, but the most effective in terms of heat transfer is considered to be built into the wall between two adjacent rooms. This approach with a small area of the building allows you to get by with one heating structure with sufficient heat dissipation.

It is not allowed to install the stove close to the outer wall of the room, because in this case it will cool down and uselessly use the stored heat - warm the street. When choosing a suitable place, the following points are also taken into account:

- ceiling height in the zone of the furnace, allowing it to fit into the space in its dimensions;

- the possibility of arranging the foundation, given that it will be slightly larger in size than the base;

- lack of floor beams and rafters in the area of the pipe outlet to the roof.

Taking these factors into account will allow you to correctly place the stove within the boundaries of the room.

Masonry materials

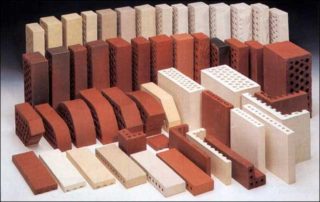

When considering the materials used during the masonry work, the existing varieties of brick products are primarily taken into account.Before choosing a layout scheme, it is necessary to clarify what size the brick is designed for, which will eliminate serious errors. The possibility of using curly wedge-shaped blanks, which are often used in laying arched vaults, is also taken into account.

For facade decoration, bricks with rounded corners or other non-standard configurations are often used. The kiln scheme used during operation takes into account all variants of the brick material, laid according to the order and the table attached to it. In addition, the following product characteristics are taken into account:

- “Branded” strength of a brick, which is understood as a mechanical load that is long maintained by the material without consequences for its structure;

- frost resistance;

- thermal conductivity;

- hygroscopicity.

The first of these parameters is indicated by the letter symbol M and a simple three-digit number indicating the indicator of the permissible load in kgf / cm². For the laying of the functional part of the furnace, brick of a brand not lower than M150 is needed. If the kiln structure is particularly massive, it will require products of the brands M200 or M250 for its construction. The frost resistance of the brick is indicated by the Latin letter F in the marking with a numerical sign next to it. The latter expresses a minimum of cycles of freezing and thawing of brick material without losing its strength characteristics.

The stove is a heat engineering facility and should accumulate heat well, gradually giving it to the room. To fulfill this requirement, a brick is selected with a thermal conductivity of at least 0.61 W / meter per degree. The exception is materials going to the exterior of the chimney, where the thermal insulation properties of the structure are important.

Hygroscopicity or the ability of a material to absorb moisture is usually expressed as a percentage of its mass.

Types of bricks

Any do-it-yourself stove assembled for the stated purposes can only work if the source material is correctly selected. The following types of bricks are used for its construction:

- silicate;

- ceramic;

- pressed stamps.

Silicate products attract specialists by the correct form, as well as smooth surfaces and a variety of colors. In their manufacture, well-purified quartz sand and lime additives are used. Ceramic bricks made from special grades of clay are ideal for laying stoves and fireplaces of various designs.

From the description of the pressed varieties of brick products it follows that they are made on the basis of culling rocks of the calcareous group: dolomite, limestone, shell rock, marble and the like. Portland cement performs the function of a binder here, added at the rate of 10% of the total mass. This type is found mainly in the original designs used in the manufacture of exotic dishes (barbecue, for example).

Conventional stoves for a home or bath are laid out exclusively from solid brick.

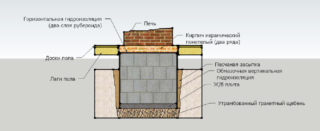

DIY oven foundation

It is possible to qualitatively make a stove for the household if a reliable foundation is prepared for it. This element of the construction of the furnace is given increased attention, since the ability to perform its functions depends on the reliability of the foundation. Before arranging it, it is important to determine the dimensions of the furnace structure and its total weight together with the chimney.

The depth of the foundation depends on the following factors:

- soil quality;

- heaving of the soil in this place;

- the depth of its freezing;

- groundwater level.

By design, the bases are monolithic, completely poured with concrete, rubble, made of small natural stones and columnar (pile). Brick stoves are traditionally built on rubble or monolithic foundations having the following advantages:

- simplicity of arrangement;

- comparative low cost of materials;

- the ability to withstand significant weight (load).

In the construction of small structures, preference is given to the rubble foundation, for the arrangement of which less money is spent.

Masonry kiln solutions

The strength and durability of the furnace being built directly depends on the correct preparation of the masonry furnace mortar, which ensures a high-quality seam. Its average thickness should not exceed 8 mm, since cracks appear in thicker joints over time, significantly reducing the efficiency of heating the surrounding space. For this, the masonry mortar is prepared from high-quality clay mixed with carefully sifted sand. According to the instructions for cooking during kneading, it is brought to a state of homogeneous mass, not containing lumps and large impurities.

There are several types of masonry mortar: skinny, normal or greasy. To obtain any of them, when mixing with water, carefully monitor the consistency of the mixture until it reaches a state similar to a thick dough. As soon as it stops sticking to the person’s hands and the trowel, the solution is ready. For laying refractory bricks, a special composition is prepared, which in addition to greasy clay includes fireclay sand, taken in the right proportion.

Features of the masonry

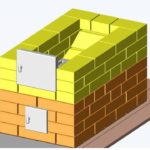

Several variants of masonry are known, schemes of which are usually attached to drawings of stoves:

- Dutch scheme;

- heating construction V. Bykova;

- Stolyanka furnace;

- Swedish stove design.

- Oven Dutch

- Bykov furnace

- Swedish stove

The most common is considered a Swede. To lay out the furnace design for this option, you will need an ordering scheme provided in many thematic articles on the Internet. In these materials, the following masonry details are painted step by step:

- how the roundness of the catch of the structure in individual rows is maintained;

- how vertical overlap at the seams in each of them is organized;

- on which row are the windows for stoves and functional niches of the furnace;

- where does the chimney tap start and how are other things laid out.

After getting acquainted with these materials, it will be possible to proceed directly to the masonry work.

The nuances of masonry

To obtain an even masonry around the entire perimeter with fixation of the position of the initial rows, cords are hung from the outside, attached at several points on the floor and ceiling. Then they proceed to the phased calculation of all subsequent rows, the evenness of which depends on the following factors:

- the correctness of applying the solution to the working surface and its distribution;

- accuracy of laying individual samples of bricks;

- compliance with the gap at the joints and in the aisle.

During the laying process, special attention is paid to overlapping adjacent layers, in which the joints of each next row are displaced by about half of the brick relative to the previous one.

Fire safety

When constructing brick kilns, the following fire safety measures must be observed:

- if there are wooden partitions at the place of laying, the minimum distance from them to the furnace is 130 millimeters;

- the recommended direction of wall insulation is from the cutting side;

- the distance of the chimney from the partitions is at least 250 millimeters.

When implementing the latter requirement, it is possible to insulate the walls by means of additional brickwork.