Autonomous gas heating gives the consumer a certain independence, allowing himself to regulate his energy consumption. Some installations can only heat the room, others can also be a source of hot water. To understand the types of equipment, you need to know the differences between single-circuit and double-circuit boilers. Manufacturers of heating plants offer a wide variety in power and functionality.

What is the difference between a double-circuit boiler and a single-circuit

Gas heating equipment can be classified according to the following criteria:

- number of heating circuits provided;

- thermal power that the unit can give out;

- level of equipment;

- appointment - household or industrial equipment.

All these plants have one thing in common - they work by burning natural gas.

Hot water and heating

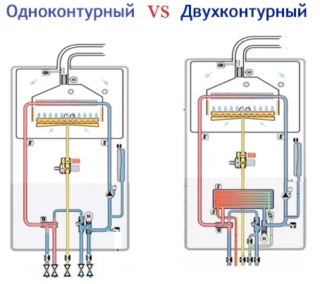

Systems in which only one heat exchanger is designed for connecting radiator lines is called single-circuit. Products of this type have a mechanically simple and reliable design.

Double-circuit units, in addition to heating, are designed to perform another task - to provide the house with hot water. If there is only one heat exchanger inside, the redistribution of the heat carrier flow between the circuits is carried out due to the operation of the three-way valve. The priority here is the heating of the liquid, which is used for domestic needs. Systems with two heat exchangers allow you to connect your own circuit to each of them.

Overall parameters and power of installation

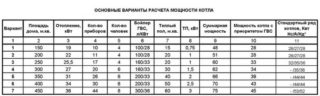

The more powerful the device, the greater will be its linear dimensions. The thermal return of single-circuit units is selected based on the area of the building, which is equipped with this type of heating. Double-circuit heaters have the peculiarity of poor heat dissipation in the case of selection of hot water from two points. Therefore, in order to avoid the appearance of cold water in a hot tap at the moment of opening the second one, it is necessary:

- install the boiler on a capacity of more than 16 kilowatts, if the house has a shower room;

- apply units with a thermal return of at least 18 kilowatts for apartments where there are bathrooms;

- use boilers with a capacity of at least 28 kilowatts for rooms where two or more taps for selecting warm water are installed.

An area of 130-160 squares of space suggests that a double-circuit or single-circuit gas boiler can often turn on, risking a quick failure of the heat exchangers.

Equipment

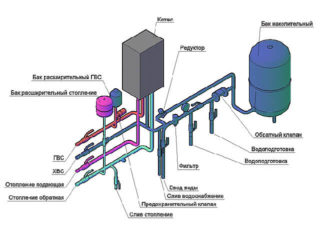

Fully equipped with a dual-circuit gas heater requires:

- valves for protection against high pressure;

- three-way action crane;

- circulation pump;

- expansion tank membrane type.

Some manufacturers additionally equip boilers with heating and hot water filters.

Single-circuit type devices, as a rule, are not equipped with associated equipment.

How to choose a boiler

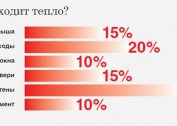

Choosing the device for the needs of the room, you must first of all take into account the power of the unit, so that it is not less than the heat losses existing in the house. The second task is to determine the number of circuits. The third - to the choice of the type of design of the device in the issue of the chimney. Other important points:

Choosing the device for the needs of the room, you must first of all take into account the power of the unit, so that it is not less than the heat losses existing in the house. The second task is to determine the number of circuits. The third - to the choice of the type of design of the device in the issue of the chimney. Other important points:

- Material of which the heat exchanger is made: stainless steel, cast iron or a copper coil.

- Product design - mounted device or floor-mounted version.

- The presence of modern automation and electronics.

- Efficiency of the device - the energy efficiency of heating directly depends on it.

Gas heating equipment must meet safety requirements during operation.

Positive and negative sides

For the most part, single-circuit gas heating units are distinguished by such advantages:

- They have a more affordable cost than analogues of a double-circuit type.

- Heat exchangers are simple in design, easy to maintain, reliable and durable.

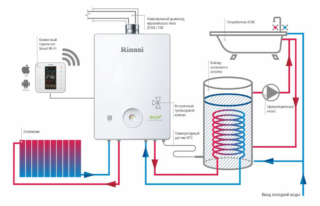

- They can work together with an indirect heating boiler.

Weaknesses of installations:

- A sufficiently spacious room is required for the installation of the apparatus and related equipment.

- System maintenance costs can be rather big.

Advantages of dual-circuit gas installations:

- At the same time, they solve the problems of heating and providing households with hot water.

- Compact and equipped with almost all the necessary additional equipment.

- Ultimately, the overall system on such a heater is much cheaper than with a single-circuit unit.

The disadvantages include:

- There is a time delay in heating the liquid.

- When opening several hot water taps, a temperature drop may occur.

In some cases, it is not possible to line up an additional circulation pump in a flow-type model.

The nuances of installing heating systems

A project for its installation is necessarily done for gas-powered equipment. If there is some freedom in choosing the location of the boiler, you can specify some points that will help more correct operation of the device.

Flowing heaters are preferably mounted closer to the place where there will be water intake.

If there are two coolant return valves, the distance from the heater should be minimal to the valve from which water is often taken.

Top manufacturers of dual-circuit and single-circuit systems

The most popular and popular boilers on the market are Italian, Korean, German and Russian devices.

- Bosh - a line of German devices with copper pipe heat exchangers with anti-corrosion coating. Equipped with advanced electronics and security systems. The service life reaches two decades.

- Viessmann - German boilers with an efficiency reaching 93%.

- Beretta - gas heaters of the Italian manufacturer for high power. The devices showed excellent performance in harsh winter conditions.

- Baxi - heating systems with a silent atmospheric burner. There are products for any capacity.

- Olympia is a Korean-made double-circuit gas boiler with an automatic weather control system.

- OJSC "Borinskoye" ISHMA BSK - boilers from a reliable series of a domestic manufacturer with an integrated liquid circulation pump.

When choosing a boiler equipment, it is worth taking a closer look at domestic products and devices made in Germany. The main arguments are the simplicity of equipment in service, the reliability of structural elements and durability.