Modern production technologies have created a laminate that can be laid on a warm floor. Previously, this could not be done, since it was deformed under the influence of temperature. Now created different types of flooring, which have their own distinctive features. To choose a laminate, you need to be able to understand its characteristics.

Laminate Properties for Underfloor Heating

Laminate for underfloor heating is a material to which special requirements are imposed.

- Must be resistant to high temperatures. The product must not deform due to floor heating.

- Low formaldehyde emissions. It is harmful to humans, so you should choose a coating with a class of E0 or E1.

- High thermal conductivity. Shows the ability to transfer heat.

- Maximum coating thickness 9 mm. If you take more, the coefficient of thermal conductivity will decrease.

- Connection to each other through locks. Adhesive bonding is not recommended due to dimensional changes during heating and cooling.

The benefits include:

- Stylish appearance. Suitable for any interiors.

- Low cost.

- Easy to install.

- Long term of operation.

- Good rigidity. You can put heavy furniture, no traces will remain from it.

- A wide range of. You can buy a stone coating or other natural materials.

Disadvantages:

- Not with all types of coating there is compatibility with warm floors.

- Risk of overheating. Incorrect installation and non-compliance with operating conditions can lead to heating of parts and malfunction.

- Edge coating with waterproof material is required.

No carpets are used on top of the laminate. They reduce heat transfer and can lead to overheating and system failure.

Coating selection

When choosing a suitable coating, they rely on the characteristics, type of underfloor heating, especially heating, the purpose of the room. The range of types of laminate is diverse, so you should decide on the selection criteria in advance.

There are several varieties of underfloor heating: electric, infrared, water. Almost any type of laminate is suitable for the water system. It is usually placed in the kitchen. The most popular coating for it is a laminate of class 33 and above. It has suitable characteristics and efficient operation. For better heat transfer use a cement-sand screed.

When choosing a cover in the bathroom, it is important to consider the microclimate of the room. The most important indicator will be resistance to moisture and high temperatures.

On electric underfloor heating

Electric types have a high intensity of heating. For this reason, the main factor when choosing a laminate is resistance to high temperature. Be sure to comply with safety requirements. The documentation should indicate that it can be installed on an electric floor.

On infrared film

The principle of film IR heating is based on electricity. For this reason, the coating requirements are almost identical as in the previous case. But with a film IR system, the heating will be more uniform, and the creation of a screed is also not required.

In the water

Warm water floor is the most common. It is characterized by ease of installation and a wide range.It has an affordable price compared to other varieties.

The laminated coating should have a special high-quality protective film to better lay the boards on the water floor. Due to temperature differences between the coating and the floor, condensation may form, which can destroy the system. It is recommended to take a thinner and moisture resistant look. Under the influence of a liquid, it should not lose its shape.

Most often, ceramic tiles or parquet are placed on the water floor. This is associated with a high degree of risk of leakage or depressurization of the system.

If the owner opted for a laminate, it is recommended to put a thermostat. It will allow you to control the heating, which will positively affect the floor covering.

Laminate with integrated heating

This is a special innovative view in which heating elements are already installed in the structure. Each board has its own heating with a certain power per square meter.

The positive qualities include:

- High system efficiency. When heating is turned on, heat goes from the inside and quickly gets into the air.

- Heat losses are reduced due to the design.

- You can lay a regular laminate to create areas without heating.

- The ability to install a thermostat to save energy.

This is a new development, so not many consumers have time to evaluate it.

Substrate Selection

Any wood flooring is laid on the substrate. It performs 4 functions:

- protection of the coating against wear due to friction on the screed;

- removal of squeaks;

- straightening irregularities;

- insulation at home.

The substrate should not degrade the temperature characteristics. The material must be environmentally friendly and not emit toxic substances and smell when heated.

It is important that the substrate does not interfere with the evaporation of moisture. Otherwise, condensation appears under the laminate, which can lead to the formation of mold, fungus and the appearance of other harmful bacteria. The optimal choice is a cork substrate with a porous structure. Foamed polyethylene and polystyrene are also suitable.

What to look for when buying

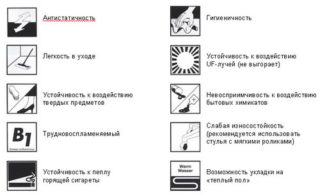

To understand what coating you need to buy, you should carefully study the labeling of the laminate. The manufacturer indicates in it all the characteristics of the material.

The buyer should pay attention to the following designation:

- A possibility of application with this or that kind of a heat-insulated floor. Water floor heating under the laminate and electric have their own different characteristics.

- High temperature exposure.

- Vapor permeability.

- Moisture resistant properties.

- Class of coverage and emissions. According to GOST, even E1 can be used.

- thermal conductivity of the laminate.

You can buy flooring and underfloor heating in a hardware store. The leading positions in the ranking of underfloor heating under the laminate are occupied by firms Caleo, Devi, Thermo.

Mounting Features

The effectiveness of the system depends on the correct installation. To do this, use the installation instructions.

- Laying is carried out only on a pre-aligned surface.

- After pouring the concrete screed, you need to wait for it to completely dry. Typically, the drying time is 1-4 weeks.

- Laminate is placed only on a proven heating system. It needs to be tested to make sure that the floor is functioning smoothly.

- After buying boards, it is necessary that they lie for at least three days in the room where they will be laid. This will allow the coating to accept the macroclimatic conditions of the room, so that their size will not change during installation.

- Optimum temperatures for work from 16 ° C to 32 ° C.Laying is done on a cold base.

- When installation is complete, you must turn on the system and gradually increase its temperature to the optimum value. The value should be increased by 5 ° C per day.

Compliance with the recommendations will allow you to properly lay the laminate on the warm floor and create an effective heating system for housing.