The South Korean company DAEWOO ENERTEC introduced to Russian consumers a warm floor XL PIPE. This is a unique heating system of a new generation. The XL PIPE electro-water floor is significantly different from the warm floors that the consumer is used to seeing.

Technical features of underfloor heating XL Pipe

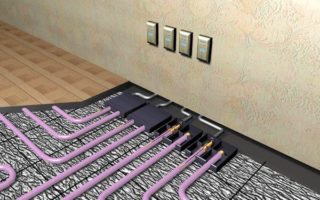

The latest XL PIPE floor system consists of plastic sealed pipes with an electric cable inside. The pipes are filled with a special fluid that quickly boils when the cable is heated.

XL PIPE can be used as primary and additional heating. To install it, you do not need a boiler and oven. Due to this, the installation of an electric-water floor requires minimal financial investment.

This type of floor heating can be used in small cold areas and in large areas. It fits into the screed up to 8 centimeters. The lining can be hard and soft. In contrast to this system, electric underfloor heating requires only solid cladding material.

The XL PIPE electro-water floor can be installed anywhere. He is not afraid of mechanical impact, the movement of furniture. In contrast, an ordinary warm floor is prone to overwriting the cable. In places where large furniture is installed, it can overheat, because of this the whole system can fail.

Advantages and disadvantages

The XL PIPE floor system is designed specifically for heating equipment in private homes and cottages. It is very popular due to many advantages:

- Suitable for installation under any basis: laminate, tile, carpet and linoleum.

- It does not require additional installation of pumps and boilers.

- The cable is in a special liquid, due to this, its overheating is excluded.

- The system is resistant to mashing, large furniture can be placed on the floor, without being afraid that the cable will be pinched and the system will fail.

- It is possible to repair without opening the screed.

- The function of adjusting the temperature in different rooms is installed.

Liquid XL PIPE warm floor is characterized by the following indicators:

- It is an economical, energy-saving system. 98% of all energy goes to room heating. Thanks to this, heat is not lost, the cost of heating is markedly reduced.

- The warm water floor is easily mounted under any type of coating.

- The design is completely safe for humans, as it prevents the emission of electromagnetic waves.

- Thanks to the innovative design, its reliability and long service life are ensured.

XL PIPE Electric Water Floors is a fully autonomous system. This type of water heating can be installed as the main source of heating. It is not afraid of moisture, therefore it is suitable for installation in bathrooms and bathrooms.

What is included with the XL Pipe System

The entire XL PIPE system of electrowater underfloor heating is offered to the consumer completely ready-made. Additionally, for installation, you only need to purchase materials for thermal insulation, it can be techno-plex, penoplex. You will also need to stock up on a reinforcing mesh 3 * 4 mm thick, a junction box and plastic clamps.

The XL PIPE underfloor heating system is available in eight configurations. They vary in power and are able to heat rooms of various sizes.The novelty is completely autonomous. It is able to function without a radiator and boiler. The kit includes:

- tube packed in a bay;

- instruction with a warranty card.

Separately, you need to purchase a thermostat.

Device and principle of operation

The innovation of the Korean system lies in the unique structure of the heating element. It is a pipe with a diameter of 20 mm, made of structured polyethylene. Inside, the pipe is filled with coolant, then a cable is inserted throughout the entire length.

The difference from conventional underfloor heating is that the cable consists of an alloy of chromium and nickel, and is coated with a Teflon sheath on top. The whole structure is hermetically sealed. Thanks to this design, the coolant inside the tube does not move, it is completely static.

The main feature of the principle of operation of the innovative electric-water floor system is that for heating you do not need to purchase a separate collector, boiler and circulation pump.

The system is installed under the screed. This ensures an even distribution of heat over the entire surface. Antifreeze acts as a coolant. Unlike other warm floors, due to antifreeze, it is always possible to achieve a stable temperature.

The main advantage of the system is that it can be used as primary heating. To increase the heating power, during installation, they reduce the installation step.

Rules for installing underfloor heating XL Pipe

The quality of heating depends on how well the warm floor is laid. For effective heating of a private house, it is important to choose the right pipes for the main by meter. To make calculations, you need to measure the flooring in the room. Next, you need to divide the smallest length by the step with which the pipe is planned to be laid. The average distance between the pipes on the highway is 20-30 cm. The digital indicator that turned out is multiplied by the longest room. The calculation of power can be done in a special table that the manufacturer offers.

Before starting installation work, it is recommended to make a project for laying the trunk. He will present a drawing containing the length, method of laying pipes, the distance between the turns. Such a project will help in the installation process and, if necessary, repair.

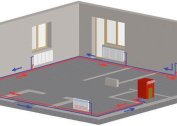

To install the underfloor heating system, you need to perform the following steps:

- Level the flooring.

- Install thermal insulation. It should be at least 5 cm thick. It is best to use technolex or penoplex.

- It is necessary to place a reflective screen on the insulation. It is needed to improve the passage of heat waves.

- To fix the trunk, you must first install the reinforcing mesh. It should be evenly distributed over the entire base of the floor. But it is necessary to observe the distance of the grid from the wall. It should be at least five centimeters.

- Pipe laying starts from the junction box, which is installed on the floor. Laying the trunk can be carried out by two methods: a snail or a snake. Most often, builders choose a snail. The first step with this method will be 60 cm, the pipe reaches the center, then turns in the opposite direction. The second step should be 30 cm. At the end, the pipe is discharged to the junction box. When laying the highway, you need to carefully monitor that there are no creases or sharp corners on the pipes.

- The laid trunk is attached to the reinforcing mesh using special plastic tapes.

- The cable is connected to the thermostat using additional wires. The temperature controller should be placed on the wall, the distance from the floor should be at least 30 cm.

- A temperature sensor is placed on the floor surface.It is better if it will be located directly on the pipe. So he can immediately catch the temperature level and give a signal to the system.

- Before filling the screed, the floor must be tested. To do this, use a multimeter. It helps measure the resistance of the material. If the test is successful, a concrete screed is made with a thickness of not more than 8 cm. It is not necessary to hide the XL Pipe warm floor under the screed. Dry mounting options are available. It is a laying of a pipe on a rough coating in specially made grooves. They are covered with a special foil used for saunas. Pipes are located on top. The laid highway is covered with GVL 2 cm thick.

- The next layer will be facing. The trunk can be fixed during installation on a wooden base. To do this, you must first make plywood tracks.

The first time you connect to full heat, it may take 48 hours. After the coolant warms up, the entire floor system begins to work as usual.

The warm XL PIPE floor system is one of the most effective ways to organize heating in country houses. The Korean manufacturer gives a guarantee of 50 years. Owners of country houses, as well as professionals in the field of heating systems, prefer XL PIPE electric-water floors due to the highest quality and ease of installation.