An electric boiler is one of the options for organizing heating in a building. There are several types of equipment powered by electricity. In addition to the well-known TEN models, electrode boilers are also available. Such equipment is highly efficient. The use of saline as a coolant contributes to the rapid heating of the liquid. In Russia, the company "Galan" is engaged in the production of innovative heating equipment. The company uses the latest developments that increase the efficiency of boilers to almost 100%.

Types of Galan boilers

The heating equipment of the company is divided into 2 types.

Heating elements

Devices increase the temperature of water or antifreeze using a tubular heating element. Inside the heater there is a spiral with high resistance. With the passage of current, it heats up, transferring energy to the coolant. The electric boiler Galan is a stainless steel cylinder. Its heating blocks are lightweight and long-lasting.

The equipment is designed for connection to a single-phase and three-phase network. It is compatible with a closed heating system that works with a circulation pump. Electric boilers are equipped with three types of automation:

- Economy - electromechanical temperature regulator MRT-15.

- The standard is the electronic regulator Navigator Basic.

- Comfort - electronic controller and electronic air temperature programmer.

TEN equipment is produced with a capacity of 3-30 kW, it is able to heat a room with an area of 30-750 square meters. m. Electrical units can be used with underfloor heating.

Electrode

The process of heating the coolant in the electrode boilers occurs due to the release of energy in the ionization process. With the passage of current, water molecules are split into positive and negative ions. The heating takes place in a special small chamber, so the temperature of the coolant rises quickly. Hot liquid has a low resistance, and the boiler gains maximum power. The operation of the equipment is controlled by automation, operating together with a room thermostat.

The coolant in the system is a special liquid or water with a set of additives recommended by the manufacturer.

Galant boiler with electrodes consumes less electricity. Depending on the power of the model, the installation heats a house with an area of 30 to 700 square meters. m. Installation of boilers is carried out without coordination with state authorities.

Pros and cons of equipment

Choosing a Galan heating system, the buyer receives several significant advantages:

- High efficiency heating system with economical electricity consumption.

- The compact body and low weight of the boilers simplify installation, do not require the allocation of a large amount of free space.

- Electrode boilers operate silently.

- With proper installation, the equipment is absolutely safe.

- The company offers a wide range of sizes.

- The operation of the system is fully automated.

- The design of electric boilers allows for the repair and replacement of damaged parts.

Among the advantages of the products are affordable cost and versatility. Electric boilers can be installed in any room: apartment, office, warehouse, private house or cottage. They do not require a chimney device, do not have combustion products. Units do not need maintenance and cleaning.

The main disadvantages:

- dependence on the electric network;

- the need for coolant preparation;

- deposits accumulate on the electrodes, reducing work efficiency;

- in devices with heating elements, when the coolant leaks, the heating element burns.

Small-sized and reliable electrode boilers are the best choice for heating cottages and other rooms of a small area.

Boiler selection criteria

In order for the heating system to function without breakdowns and provide a comfortable temperature in the house, it is necessary to determine the main characteristics of the boiler before buying. When choosing a model, the following criteria are taken into account:

- Electric boiler power - the parameter is the main calculated value of the heating system. The average figure is 1 kW per 10 square meters. m square. For more accurate calculations, you can use the online calculator. Experts recommend choosing equipment with a power reserve of up to 10-15%.

- Unit dimensions - the size of the boiler will help determine the installation location. It is important to know the mass of the unit and the method of placement. Lightweight compact Galan models are installed near radiators, it is difficult to recognize the boiler in them.

- Degree of automation - a mechanical control unit is suitable for temporary use. The electronic regulator precisely controls the parameters of the system, ensuring economical consumption of electricity. Reliable automation shuts down the unit in case of overheating or short circuit.

The cost of equipment is another significant criterion. The electric boiler Galan is offered at a reasonable price.

Mounting Features

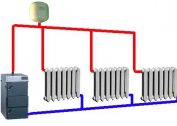

When installing a heating system using an Galant electric boiler, two pipelines must be connected. The upper line serves for distribution, and the lower one - for collecting the cooled coolant. When installing the system, the manufacturer's recommendations for the materials used are taken into account:

- The use of cast-iron radiators eliminates the advantages of electrode assemblies.

- Elements of the system must have close electrochemical activity or isolate upon contact.

- The first meter of the pipe must be made of non-galvanized metal.

The unit must be positioned vertically and located above the radiators. The total power of the heating batteries must not exceed that of the boiler. The manufacturer advises to insulate the area from the boiler to the upper distribution pipe. This will reduce the loss of local overheating of the pipeline and accelerate the circulation of the liquid.

The electric boiler is necessarily grounded. To avoid problems with its operation when the voltage drops, it is worth installing a current normalizer. When choosing a location for the temperature sensor, the recommendations of the manufacturer are taken into account. They also rely on the instructions when pouring liquid into the system. Its volume should be 8-10 l / 1kW.

Popular models

The company's products are represented by three popular series: Hearth, Geyser and Volcano. Models differ in power and dimensions.

Hearth

The junior representative of the line has a power of 3 to 9 kW. Units that work with heating elements have a Turbo prefix in the name. The design of the models includes 3 heating elements of various sizes. The equipment is used for heating small rooms, the maximum area of 100 square meters. m. Electrode assemblies are presented in three versions - 3, 5 and 6 kW. The need of the system in the coolant is 25-70 liters. The weight of the boilers is about 1 kg. The energy consumption for starting the heating system is about 2.5 kW.

Geyser

Geyser modification is the most common option. Its popularity is explained by good power indicators with average electricity consumption. The model is suitable for heating a private house up to two floors. The Turbo geyser is available with a power of 9 and 12 kW, electrode installations - 9 and 15 kW.Equipment requires pouring into the system up to 300 l of coolant. Power can be supplied from a single-phase and three-phase network, but always with an RCD connected.

Volcano

Powerful units are designed for heating large areas. They connect only to a three-phase network. The functional boiler is designed for autonomous heating of residential, industrial and commercial buildings. The Volcano line is installations with a capacity of 25.36 and 50 kW. 150-500 l of coolant must be poured into the system and pressure must be maintained up to 2 atmospheres. The equipment is equipped with automation at the buyer's choice. Climate control and a programmer are added to the electronic control unit.

- Volcano model up to 50 kW

- Geyser Model 9 kW

User manual

Galan electrode boilers are created based on the development of the defense industry. They are universal in application, recommended for various regions of the Russian Federation. To prevent errors in the operation of the equipment, it is necessary to study the manufacturer's instructions. During the heating season, the coolant level is monitored. If its volume is less than 1/3 of the expansion tank, distilled water or antifreeze is added.

To extend the life of the heating system, the manufacturer offers several types of technical fluid for Galan boilers. With the help of the corrosion inhibitor Protector, rust, scale and dirt are washed out of pipes and radiators. This procedure is necessary during operation and before the first start of the system. With preventive washing, the solution is in the system for 6 days, then completely drains.

The coolant "Aquarius" is a prepared composition with zero resistance. It is inert and safe, does not cause corrosion. Its use extends the life of the boilers. Propylene glycol-based BlueStar antifreeze is used as an anti-freeze coolant.

The manufacturer advises that after the end of the heating season, clean the housing of the unit, check the reliability of fixing the wires in the terminals. The reliability of grounding and the automation unit is also controlled. In the absence of electricity, the appearance of moisture on the boiler body, grounding problems, the equipment immediately turns off. Unit repairs must be performed by certified specialists.

With Galan equipment, heating is efficient and economical. Models with a heating element can be used at night, when reduced electricity rates apply. Electrode aggregates consume 20-30% less energy, therefore, heating consumption is low.