The surfaces of walls, roofs of various types, floors of attics and other parts of the structure always need a high-quality insulation that does not allow cold and is able to maintain the optimum temperature in the room. The innovative insulation Knauf Cottage is popular among builders due to its high quality and optimal performance. It can be used for its intended purpose and in other situations that everyone should know about.

What is Knauf Cottage

Insulation Knauf Cottage belongs to the category of non-combustible elastic insulation, is characterized by optimal water-repellent qualities and is recommended as insulation for walls and pitched roofs. The material is produced in the form of compact plates with a convenient density and a thickness of 50 or 100 mm, which makes it possible to select it taking into account the size of structures in a particular room.

Installation using plates from the Knauf Cottage series is not difficult even in the absence of experience. The shape of the plates allows you to mount them in several approaches, to insulate the walls or roof with a single layer without the formation of cracks and joints. The material is easily cut and adjusted to the required dimensions, which ultimately saves time spent on installation. In addition to thermal insulation, the boards have ideal sound-absorbing properties and are a universal type of building material.

Advantages of insulation

Heater TeploKnauf Cottage is produced by the company of the same name in Germany, which has a proven reputation as a reliable manufacturer of building materials. This convenient plate material belongs to the premium class, is made from substances of natural origin that do not provoke allergic reactions, and is completely safe for health. It reliably retains heat inside the space and has an optimal level of noise reduction, is resistant to fire and meets fire safety requirements.

The list of the main advantages of the insulation includes:

- good biological resistance - the material is not affected by insects, as well as rodents;

- comfortable texture, lack of synthetic odors, ease of work;

- maximum long service life;

- the ability to decrease in size for a more comfortable movement;

- minimum shrinkage and load on the walls;

- a guarantee from a company for a period of more than forty years;

- natural composition, excluding the presence of dyes, bleaches and other substances.

High-quality insulation helps save money on heating the premises in the winter due to the low level of thermal conductivity compared to standard brick.

Scope of application

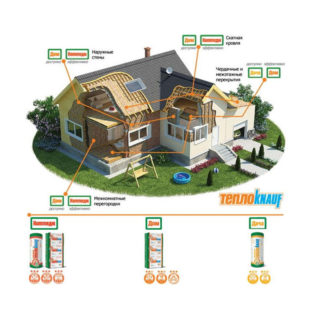

Heat insulation Knauf Cottage or Cottage Plus is most often used to insulate walls inside, less often outside. Basically, it is used to conduct external insulation, which allows you to move the freezing points to the outer part of the wall and concentrate more heat inside the building. The material is also well suited for suppressing noise conduction and mounting underfloor heating; it is used both separately and in combination with auxiliary parts.

Due to its optimal thickness and technical characteristics, it has proven itself as the basis for ventilated or non-ventilated thermal insulation of roofs. The insulation is mounted in the process of working with roofs of various types, for example, pitched.It is widely used for other purposes, including to prevent freezing of non-residential premises, including warehouses and industrial buildings, as well as insulation of basement and foundation plots.

When working with balconies, basements and loggias, Knauf Cottage series stoves with an increased level of strength are often used. They do not shrink and have perfect thermal properties.

Specifications

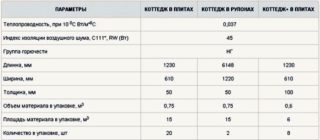

Plates are produced in the following versions: TeploKnauf Cottage and TeploKnauf Cottage + with factory thicknesses of 50 and 100 mm, respectively. Dimensions of standard plates are 1230x610 mm, in rolls 6148x1220 mm, which makes it possible to use the first option for thermal insulation of houses in the Southern and Central regions, the second for Siberia and the territories of the North. The universality of the material and its compliance with a high class of reliability makes it possible to use it for complex insulation of structures of summer houses and private houses, as well as sound insulation in partitions between rooms.

The technical parameters of the plates include the optimum value of thermal conductivity equal to 0.037; acceptable level of sound insulation with an index of 45. The material is non-combustible and has a high resistance to fire. The volume of plates in rolls and packaging is 0.75 m3, the area is 15 m2, each package contains 20 pcs of plates and 2 rolls. The insulation is well combined with other building materials of the brand, for example, Technonikol mineral wool slabs and Technofas Cottage.

TeploKnauf Cottage + is not sold in rolls, it is sold mainly in the form of plates, which are mounted much faster compared to a material having a thickness of 50 mm.

Mounting Features

When installing mineral wool brand Knauf Cottage, it is necessary to follow the manufacturer's recommendations and basic rules so that the result is as perfect as possible. The installation process consists of several stages and includes mounting the frame, the insulation itself, as well as applying a vapor barrier film. This process can be handled independently if you have skills in the field of construction and finishing work or entrust the installation to professionals.

Frame

The primary wooden frame is necessary for the direct installation of insulation on the walls. Without it, the material will not hold. Before installation, the walls are cleaned of unnecessary elements and the bars are made of wood, which are treated with a refractory composition. They are fixed horizontally and vertically on the walls from one corner to another, in the presence of irregularities make special substrates from various materials.

The bars are fixed with 75 mm screws, each fastener is installed at a distance of at least 40 cm from each other. After installing the first beam, it is necessary to measure 58 cm from it, since the width of the plate is 61 cm, then the second and subsequent bars are fixed in compliance with this distance. The windows are framed with horizontal and vertical bars taking into account the plane of the wall.

If necessary, you can use additional substrates to align the surface of the walls and fix all the bars with plates as reliably as possible.

Insulation Installation

Plates are installed starting from the corner, they are squeezed a little and placed between the bars, then fixed to the wall with the help of special fungi. For one plate, at least 3-5 fungi will be required, taking into account the material in one package, each of them is mounted in a through hole with a diameter of at least 6 mm, made by a puncher or drill. The insulation can be cut according to the size of the spacers using a paint knife. After filling all the cells between the bars go to the installation of the film.

Installation of vapor barrier film

The film is necessary to prevent the formation of condensate inside the insulation, if it is present, the vapor particles simply go outside to meet the cold air. It must be installed with the smooth side up according to the instructions, each strip is placed from the bottom up taking into account an overlap of 10 cm or vertically from the corner. For the most reliable fastening, the film is sewn to the bar tree with the help of a construction stapler. Also, the seams must be glued with double-sided tape so that they do not disperse. After the walls are sewn up, you can proceed with the installation of siding.

Siding

For siding, bars of 25x50 or 25x100 mm are used, special self-tapping screws from 35 to 55 mm long and a screwdriver. The frame boards are impregnated with a bioprotective solution and cut according to the required length, which should correspond to the length of the boards for the first frame. Next, you need to form the corners and fasten them to the horizontal bars on the first frame vertically, the following boards are attached at a distance of at least 25 cm from each other. Following these rules helps to make the structure more durable in addition to the standard insulation procedure.

It is important to always follow the manufacturer's recommendations and not combine materials that are incompatible with each other. In this case, the insulation copes with its direct and additional functions.