The development of the construction industry requires heat-insulating materials with improved technical characteristics. Modern heaters must be universal, reliable, safe and durable. Technopollex expanded polystyrene from the Russian company Technonikol deservedly leads among the materials of its segment. It is characterized by high strength, low water absorption and ease of installation.

Technoplex production technology

Synthetic insulation is made from polystyrene granules. Raw materials are loaded into the hopper. Modifiers are added to it that improve the properties of the final product. Among them, flame retardants to reduce flammability, stabilizers, antioxidants. The unique TechnoNIKOL additive is the smallest carbon particles. They increase the strength and thermal insulation properties of the final product. Foaming of the granules occurs using carbon dioxide. All 7 plants of the company introduced environmentally friendly freon-free production technology.

Under the influence of high temperature and gas supplied under pressure, the raw material melts and foams. The mass is extruded from the extruder in the form of a tape. After solidification, it is cut into sheets of standard sizes and shapes. Plates are packed in a polyethylene thermoshrinkable film.

Specifications

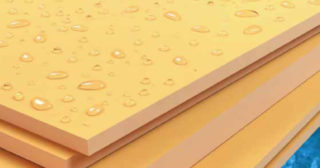

Technoplex XPS extruded polystyrene foam has a uniform structure with closed gas cells. The number of closed pores is almost 100%, which ensures minimal water absorption and stable thermal conductivity. Graphite nanoparticles in the composition of the material give it a grayish tint, increase the strength of the plates.

Technical characteristics of the insulation Technoplex:

- thermal conductivity index - 0.032-0.037 W / (m * K);

- water absorption - 0.2%;

- vapor permeability - 0.014;

- density - 26-35 kg / m3;

- compressive and bending strength - 100-150 kPa;

- operating temperature - from -70 to + 75 ° C;

The light weight of the insulation simplifies transportation and installation, the total weight of the building structure increases slightly. High resistance to deformation allows the use of plates in areas with high load. They are effective in arranging all types of roofs (pitched, flat), external insulation of the foundation, experiencing soil pressure.

Pros and Cons of Material

When choosing a heater, its advantages and disadvantages are taken into account. Polymer materials with closed gas-filled cells provide heat and sound insulation of the structure. Unlike foam, extruded plates have mechanical strength, which significantly expands the scope of their application and increases the service life. Technonikol products are popular due to numerous advantages:

- Low water absorption allows the use of slabs in any construction sites. The characteristics of the insulation do not change in conditions of high humidity.

- Technoplex - insulation, which is effective with a small thickness. With internal installation, it saves usable floor space.

- Low coefficient of thermal conductivity provides a comfortable temperature in the house. The cellular structure of the material prevents the spread of cold and noise.

- TechnoNIKOL products have the lowest vapor permeability coefficient among heaters.

- Extruded polystyrene foam sheets have a long service life of about 50 years. During operation, they are not deformed.

- Synthetic insulation is not covered by mold or fungus. The robust structure makes it unattractive to rodents.

- Expanded polystyrene is environmentally friendly, does not emit harmful substances. The composition of the synthetic product does not contain formaldehydes and other components hazardous to human health.

With Technoplex boards, building insulation becomes easier and faster. They are easily cut with a tool at hand, do not crumble, have a convenient shape and size.

Material disadvantages:

- high combustibility class G4, easily flammable and emits caustic smoke;

- destroyed by organic solvents;

- UV protection required.

The cost of XPS sheets is higher than the popular foam or mineral wool. With large volumes of insulation, the material will be expensive.

Release form and scope

The insulation is produced in the form of rectangular plates with a smooth surface. Products have standard linear dimensions, the dimensions of the extruded polystyrene Technoplex are 50x580x1180 mm. The thickness indicator ranges from 20 to 100 mm. Length and width can be 1200 and 600 mm, respectively. The edge of the sheet has a characteristic edge that simplifies the joining of plates and reduces heat loss due to the tight fit of the insulator.

The manufacturer recommends Technoplex insulation for use in private housing construction. Strong moisture resistant XPS boards are used for insulation:

- foundation and basement, arrangement of fixed formwork;

- external and internal walls;

- interior partitions;

- balconies and loggias;

- floors, including in the "warm floor" system;

- roofs and attics.

Extruded polystyrene foam is used in the construction of farm buildings, the construction of greenhouses, it is mounted on external communications pipes, under the road surface. For insulation of facades and walls, the XPS Technoplex FAS modification offers. The surface of the plates is machined by a mill, grooves are applied to it. Rough sheets provide high adhesion to the substrate. The material is prepared for applying plaster and adhesive solutions used in the thermal insulation of facades, socles and other building envelopes.

Mounting Features

To independently perform thermal insulation at home, special skills are not required. It is enough to study the technology of work on a specific site and adhere to tips and recommendations. Heater TechnoNIKOL Technoplex is fixed with special glue and plastic dowels.

Floor insulation

Thermal insulation of the floor with XPS boards can be carried out on the ground and concrete screed. The first technology is used in rooms where the base will not experience high loads. Preparation begins with backfilling a layer of crushed stone. On top of it sand is placed with a layer of up to 10 cm. Having rammed the base, sheets of expanded polystyrene are laid. Technoplex is poured with a concrete screed.

When warming a concrete base, it is necessary to check its level. All differences are leveled with a solution. Expanded polystyrene is mounted completely dry and clean base. In the basement underneath is a layer of waterproofing. The thickness of the sheets depends on climatic conditions, usually it is 50-80 mm. The insulation is covered with plastic wrap, a damper tape is laid around the perimeter. Cement-sand mortar is poured.

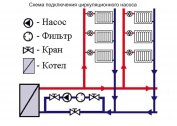

If heating is provided by a water or cable electric underfloor heating system, the heating elements and pipes are placed under the screed layer.

Wall insulation

To fix the sheets on a vertical base, special Geresit or TechnoNIKOL adhesive mixtures are used.The process of insulation begins with the leveling, cleaning and priming of the walls. Installation starts from the bottom. Each next row is stacked with an offset of half the length of the sheet. The adhesive composition is applied to the surface of the insulation, the plate is pressed against the wall for several seconds. For additional fixation, 5 dowel-umbrellas are installed. They are placed in the corners and in the middle. The seams between the sheets are filled with foam.

After the glue has dried, the reinforcing layer of the fiberglass mesh is laid on the surface of the Technoplex. Finishing is done by plaster. After the solution dries, the finish lining is performed.

Foundation insulation

Foundation insulation is recommended to be carried out from the outside. Previously, the surface is covered with a layer of waterproofing. An adhesive mixture is applied to the polystyrene foam boards around the perimeter and in the center. Pressing to the foundation, hold for 1 minute. Sheets are laid tightly to each other, in subsequent rows are performed with offset joints. To dry the glue, 2 days are given, then the insulation is fixed with plastic dowels. Finishing is done with plaster mortar along the reinforcing mesh.

Roof mounting

Thermal insulation of the roof is performed inside and out. In the first case, it is possible after the construction is completed. Plates can be laid according to frame and frameless technology. On a flat roof, the material is placed on a waterproofing coating. Plates are laid apart, if necessary, in two layers. The insulation is covered with a geotextile cloth. Finishing layer - concrete screed or backfill with gravel.

The pitched roof is isolated along the crate. The bars are packed in increments of 600 mm equal to the width of the plates. Technoplex is laid in the crate, the joints are filled with foam. The insulation layer is closed with a vapor barrier film. On top of the material, a counter-grill is stuffed for the installation of the finishing

Technoplex insulation has all the necessary characteristics that provide reliable and durable insulation of the house.