The heating register is a device for heating a room made of horizontally located one or more smooth-walled pipes that communicate with each other due to vertical connections. Traditionally, heating registers are used for heating non-residential premises - a warehouse, a garage, a workshop - but they have also found application in residential buildings. These heaters are used in rooms with stringent cleanliness requirements - their smooth surfaces are easy to clean and wash. Heating registers have various modifications, which vary in design, shape and material.

Types of Registers

Parallel connected communicating pipes, which are a heating register, differ in material and design.

Aluminum

Lightweight and aesthetically looking aluminum heat registers are among the most efficient in terms of heat dissipation. Due to their low weight and size, corrosion resistance and a long period of operation, they are successfully used in private homes and office buildings.

Such registers are not widely used due to their high cost and increased requirements for the quality of the coolant.

Cast iron

The best indicators of heat transfer have heating systems made of finned cast-iron pipes. A thick-walled pipe with a large number of ribs effectively transfers heat and cools for a long time.

Installation of cast-iron finned systems is carried out using bolts and paronite or rubber gaskets to give tightness.

This is one of the best ways to solve the heat supply problem of a private house - cast iron is not demanding on the quality of the coolant, its service life is almost unlimited.

Cons of this design:

- bulky look;

- significant weight;

- the need to manufacture massive support legs;

- fragility.

Cast iron registers have long been used in industrial boiler houses and private homes, their popularity does not decrease over time.

Copper

In networks with wiring from copper pipes, the manufacture of a copper register is effective. Due to the high thermal conductivity of copper, such heating elements have small dimensions and a beautiful appearance.

Copper pipes are easily bent and welded only at joints.

Copper heating systems are not widespread due to criticality to operating conditions:

- the coolant must be chemically neutral, clean and not contain a solid fraction;

- the heat supply system, including fittings, should be all made of copper or compatible alloys - bronze, brass, chromium and nickel;

- reinforced grounding is necessary - otherwise corrosion will begin;

- copper is a soft material, it requires a protective screen or casing.

All this forms a high price and explains the lack of increased demand for copper registers.

Steel

For the most part, heating registers are made from smooth steel pipes. Preference is given to electric-welded or water-gas supply types. The pipeline made of them withstands considerable pressure, is resistant to mechanical damage and is undemanding for the quality of the coolant.

For the manufacture of the heating system, you can use a round or profile pipe.The heater will turn out to be more compact in size, but it is significantly more difficult to work with it, the hydraulic resistance is higher.

The register of steel pipes can be made of stainless steel - these types of heaters are optimal in bathrooms. Stainless steel towel rails can be of different sizes and configurations. The only negative registers of stainless steel pipes is the high price.

Stationary and mobile registers

If the heating system is stationary, a heating boiler is needed for its operation, where the heat carrier is heated.

Such stationary systems are fastened with brackets fixed on the walls. For massive systems, a combined form of fastening is used - in addition to fixing to the wall, support posts are placed under the lower pipes.

In the case of mobile execution, a heating element is installed in the lower part of the system, which performs the function of a heater. At the top is an expansion tank with a capacity of 10% of the volume of the system, taking into account the increase in internal pressure during heating.

It is optimal to use oil or antifreeze as a coolant in mobile heaters - they do not freeze at low temperatures.

The design is included in the 220 V network and is equipped with supporting legs or wheels for ease of installation and movement.

Advantages and disadvantages

Like any appliance, metal heating registers have their strengths and weaknesses.

Benefits:

- Provide uniform heating of rooms with a large area.

- Low hydraulic resistance in smooth horizontally located media allows you to use the system with natural circulation, without using pumping.

- Large-diameter pipes used for heating are little susceptible to siltation and do not require flushing.

- The life of metal registers is more than 25 years.

- The surface of round pipelines is slightly dirty and easy to clean - this is the best choice of heating for rooms with increased sanitary standards.

- The heating register is easy to manufacture and can be made by yourself at home.

Disadvantages:

- The heating surface per unit length is small, which leads to an increase in overall dimensions.

- It requires a large number of pipes.

- The system needs a large coolant displacement, due to which the system has high inertia and slow adjustment.

- Budget models are outwardly unattractive, and design developments are notable for their high price.

Features of heating registers of simple design with good performance indicators determine their scope.

Calculation of the required number of registers for heating

Before proceeding with the calculations, it is necessary to determine the temperature regime in the room and the heat loss in it. This will determine the size of the heating register.

Such a heating system is made according to drawings from pipes with a diameter of 32 to 100 mm. An increase in the diameter of the pipeline naturally leads to an increase in the volume of the system and its increased inertia, and difficulty in adjustment.

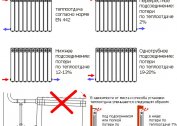

If there is more than one pipe in the registry, the distance between them is determined as follows:

- not less than 1.5 pipe radius, otherwise heat transfer decreases;

- increasing the distance between horizontal media will lead to an increase in overall dimensions, which is inconvenient in installation and operation.

Mono calculate the heat transfer of one pipe independently, substituting the pipe dimensions and temperature data in the formula:

Q = 3,14 · D · L · K · (Tr - To)

- Q - the amount of heat generated by the pipe;

- D - diameter, m;

- L - long, m;

- K - the heat transfer coefficient for a steel pipe and water (coolant) is 11.3 W / m² · ° C;

- Tr - water temperature in the register;

- To - temperature in the room.

You can calculate the register based on the average heat transfer value of 1 m steel pipe at a water temperature of + 90 ° C, and a room temperature of + 20 ° C.

As an example:

- with d 35 mm the area will be 0.56 m²;

- with d 57 mm - 0.94 m²;

- with d 89 mm - 1.37 m².

Knowing the heat transfer of 1 m pipe and the area of your premises, you can calculate the required number of pipes.

For registers with two or more rows, a reduction factor of 0.9 for each thread is used.

Register setting

Installation of a heating system with registers is not complicated. For convenience, all elements of the system are harvested and welded outdoors. Further assembly can be carried out using welded work or on threaded joints, but this is less reliable.

An air vent must be installed on the upper pipe of the heating register to bleed air from the system.

Ready-made registers are mounted to the wall or placed on a support. For massive products, you can use the combined method - brackets and racks. To improve the heating of the room, the register is fixed as low as possible to the floor.

To ensure the movement of the coolant, the installation is carried out with a slope of 0.05% in the direction of fluid flow.

DIY making

To assemble the register yourself, you must at least be a good welder. For home-made radiators, calculations and drawings are not needed, high-quality welding is needed.

One of the popular models is the “samovar”. This is a portable register filled with oil or antifreeze. A heater operating from 220 V is inserted into the lower pipe, and an expander is welded into the upper pipe. As long as there is electricity, this system will successfully heat the room.

There are many heating systems, all have their pros and cons. Compared to the performance of a bimetallic battery, registers are largely losing. But due to the low price and good heat transfer, they will be in demand in the heat engineering market for a long time to come.