Thermotechnical equipment of various modifications and capacities is produced in Russia. Among them are gas heating units, in particular boilers Ochag. They are reliable in operation and have a low price for this class. This contributes to their widespread use for heating manor and country houses located far from heating mains.

Advantages and disadvantages of boilers Hearth

The owner of the Ochag equipment brand, ServisGAZ, has been operating since 1993. The design of the units was developed by the specialists of the design bureau, here it is constantly being improved, the introduction of new technologies and materials. At the enterprise, you can purchase individual components if you need to replace them. All equipment is manufactured in accordance with the requirements of ISO 9001-2011.

The advantages include the following characteristics:

- a wide range of models, providing the choice of the best look;

- stable work;

- non-volatility from external sources;

- high performance;

- simplicity of installation and management;

- low fuel consumption;

- low price;

- compact size and nice appearance.

Units have features of work:

- the pipe system should be sloped to allow circulation of the coolant;

- for the boiler to work, it is necessary to equip it with a water pump and a turbo nozzle.

For heating systems of this type, additional equipment ensures uninterrupted operation and is not a drawback.

Device and specifications

The heating boiler can be single-circuit, double-circuit or combined.

Single-circuit boiler

It has a cast-iron heat exchanger; natural gas is used for heating. This is a complex configuration; installation requires a large number of parts. Its functions include only heating. For hot water, an additional boiler is installed.

Double-circuit boiler

Equipped with two heat exchangers. Used for central heating and hot water. For heating, natural gas is used. This is a compact installation, it works in automatic mode. To simultaneously heat the heating batteries and produce hot water, a heat accumulator is installed.

In the absence of a heat accumulator, when the hot water tap is opened, the pressure in the heating system drops, the temperature decreases. If the boiler is located far from the place of consumption, hot water does not appear immediately.

Combined installations

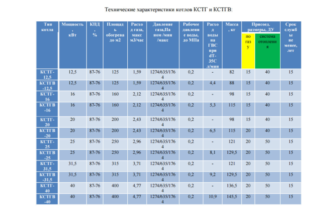

These are universal boilers with a steel heat exchanger (KSTG, KSTG). The unit can operate on fuel oil, solid fuel, natural gas. It is used for heating rooms with an area of 400 m2 and hot water, has an internal water heater. Equipped with gas automation, which reduces the flow of gas with increasing pressure.

Gas boiler Hearth has the following specifications:

| Characteristics | Brand of boiler | ||

| KSG-7AT | KSTG-16 | KNG 24 | |

| A type | Convection gas heating | ||

| Fuel used | Converting to liquefied natural gas | Natural gas or solid fuel |

Converting to liquefied natural gas

|

| Appointment | Heating | Heating |

Heating and hot water

|

| Mounting method | Floor | Floor | Wall |

| Efficiency | 85 % | 75% | 90% |

| Power | 7 kW | 16 kW | 24 kW |

| Power supply | Missing | Missing | 220 V / 50 Hz |

| Life time | 15 years | ||

| Guarantee | 36 months | ||

The parameters of three commonly used brands of the heating unit Hearth are given.

Marking boilers Hearth

The brand of the boiler has letter designations, which are deciphered as follows:

The brand of the boiler has letter designations, which are deciphered as follows:

- K is the boiler;

- C - steel heat exchanger material; H - cast iron;

- T - used to work on solid fuel;

- G - equipped with gas burners;

- B - has a water heater in the design;

- M - to it it is possible to mount TENy and the expanded fire chamber;

- the number indicates the capacity of the boiler, the first digit for operation on solid fuel, the second on gas.

For example: KSG-7AT is a boiler with a steel heat exchanger, equipped with a gas burner with a power of 7 kW, which has SABK-AT automation. KCHTG-16 modification: a boiler with a cast-iron heat exchanger runs on gas and solid fuels with a power of 16 kW without installing automation.

Ignition sequence

The heating systems of the hearth are equipped with automation, which regulates its operation and facilitates ignition. To start the unit with SABK-AT automation, the following procedure is performed:

- Open the gas supply valve.

- Place the handle in the “Ignition” position.

- The start button is turned on and held for 10 seconds.

- Press the piezo ignition button several times, in its absence, ignite the gas with a match.

- The Start button is held for 20-25 seconds until the thermocouple warms up. In this case, the magnetic plug holds the gas valve in the open position.

- The handle of the unit is turned to position 5 and achieve stable combustion of the gas burner.

- On the gas block set the desired temperature.

The ignition algorithm for other brands may differ in the position of the handle of the unit, which is indicated in the instructions for the automatic system.

Possible malfunctions

The main problems associated with the operation of the boiler are related to the operation of the burner: the flame dies out or burns weakly. The reason may be the following:

- reverse thrust;

- draft;

- strong wind outside;

- lack of gas in the pipeline;

- gas valve malfunction;

- nozzle clogging;

- problems with gas equipment.

In the event of any malfunction of gas heating, it is not possible to find out the cause or repair it yourself. First of all, it is necessary to shut off the gas supply from the highway and call the gas service. Repair of gas equipment must be performed by a specialist.

Model Overview

Characteristics of the most popular modifications of equipment Outbreak:

- KNG boiler 24. Compact wall-mounted unit, double-circuit. Modern design allows you to install it in a living room, works silently. The maximum productivity is 24 kW, gas consumption is 2.5 cubic meters per hour, efficiency is 90%.

- KSG-11 model. Floor-mounted, steel heat exchanger, productivity 11 kW, gas consumption 1.34 m3 / h, efficiency 90%. The design allows the use of EUROSIT 630, SABK-AT automation.

- KSTG-16 boiler. The simplest single-circuit floor unit, power 16 kW, runs on coal and gas, efficiency 74%, is not equipped with automation. Designed for heating rooms up to 160 m2.

- Model KSG-10 AT. Floor heating installation with a power of 10 kW. It works on natural gas, you can change the nozzles for heating with liquefied gas. Compact, lightweight, equipped with automatic control devices SABK-AT.

- KSG-7 boiler E. Budget, the choice of functions is limited, the unit power is 7 kW, the efficiency is 85%. Heats the room 80m2 area. Single-circuit, floor-mounted, works stably at low pressure in the network. Small size, modern design, low cost makes it popular when choosing to heat small buildings.

- Parapet modification. It is hung on the wall. Smoke exhaust is carried out through the pipe supplied. Two types are produced - single-circuit KSGZ and double-circuit KSGZV. The boiler body is covered with a layer of mineral wool insulation, it can be removed to clean the heater from scale. Productivity 85%.

Ochag brand boilers are not the best among modern heating equipment. Their advantage is low cost, simple construction and maintenance. You can purchase units with a wide range of features and capabilities, with full automation control at a higher price. This budget option does not imply long-term operation, the service life of the brand is 10-15 years.