A pressure pump is required to test the heating system after it is installed and started. Checking with such a device is needed not only after the initial installation. It is used after replacing the mains to transfer the heat carrier and their auxiliary parts, as well as before the start of each heating season. A pump for pressure testing heating pipes helps to identify malfunctions in the early stages, including the presence of corrosion and damage to the connecting elements. Devices of this type are divided into several varieties and have their own characteristics that must be considered when buying.

How does a pressure pump work?

During operation of the device, the pressure in the heating system increases, which makes it possible to evaluate its performance. There are two ways to pressurize, depending on the type of device: by pumping air or filling with liquid. The second option is used much more often, since the air method does not allow to qualitatively test crimp pipes. In the process, the fluid is fed into the system, after which the device is left in working condition for several hours. The pump for crimping the heating system operates according to the standard scheme. After connecting it you need:

- fill the portion of the pipe to be tested with liquid or air (if not the entire system is checked, the necessary part is limited by shut-off valves);

- increase the pressure to the desired level, controlling the data using a manometer;

- after crimping for several hours, take the system indicators and compare them with the source data;

- if the source data differs from the current ones, check the system for leaks or depressurization.

If there are malfunctions in the heating system after checking with a pressure tester, they must be repaired. After the test procedure is carried out again to make sure the pipes are working.

Types of pumps

The pressure transformer or press for pressure testing of heating can be manual or electric, depending on the type of drive. The surge arrester is a professional construction tool designed to test and flush systems, components, assemblies and small elements of systems. According to the principle of action, the pumps are divided into diaphragm, piston or rotary vane. Choosing the right device is based on the needs and type of system you need to test.

Hand press

Manual devices are inexpensive, lightweight, and do not cause problems during transportation and during operation. The operating pressure of the devices does not exceed 500 atmospheres. Pumps are supplemented with a tank, built-in pressure gauge and special hoses. Buyers prefer to choose manual budget options, because in this case you can get the device itself and additional equipment. The main disadvantage of such crimping machines is low productivity. Due to the simple design, they are used for small volumes of work or in sections of pipelines where there is no power or water supply.

Electric

An electric compressor designed for crimping a heating system is characterized by high performance. The main advantage of this type of pump is its good working pressure and the presence of an electric drive, due to which a specialist can practically not participate in the process.Electric pumps are quite mobile, despite the large weight, but they also have disadvantages, for example, increased demand for power and high cost. They are suitable for automatic fluid injection and tightness testing of closed systems. It is the best choice for pipelines, tanks, plumbing and heating equipment for space heating.

Characteristics of crimpers

Hydraulic or standard presses for crimping pipelines work according to the standard principle. During operation, they suck in the liquid, if it is not enough, the end of the pump is lowered into the tank to the end. In some models of devices there are special tanks that significantly simplify the heating pressure test procedure. During the operation of hand pumps, the pressure in the system is limited to 500 atmospheres. They can work on ordinary water, antifreeze or hydraulic oil.

Devices can have standard or miniature sizes. Mini-options can be used to quickly measure the pressure and tightness of individual elements. Hand held devices are ideally suited for hydraulic testing of machines, mechanisms, boilers and pipelines. Electrical options are more convenient and able to withstand the highest possible pressure level created by the pump. Devices of this type are equipped with an electric drive and a switch with a signal lamp.

How to make the right choice

When choosing a pump, it is necessary to take into account the total capacity of the system that undergoes the procedure, and the frequency of crimping. Models of various brands are presented on the market, which must be selected depending on their type. Manual models have a simplified design, do not cause difficulties and are inexpensive. But to create the right level of pressure when working with them, you need to spend more time, unlike pumps with an electric drive. Devices differ in terms of operating time and are capable of delivering results with different accuracy, which is influenced by the power of a particular model.

If a low power pump is used during the procedure, it will take longer to test, since such devices are slowly filled with water. It is necessary to choose a crimping machine taking into account the dimensions of the pipeline system, which is subjected to verification. If we are talking about a private house, you can purchase a special supercharger that lets 2-3 liters of liquid per minute. For multi-storey buildings and heating mains, circulation pumps are used that provide continuous fluid movement inside the system.

Installation and use of the pump

Crimping machines and hydraulic presses of various calibers are used to test heating and water supply systems, as well as plumbing installations. With their help, they check the integrity of individual sections and identify various malfunctions. First of all, testing with the crimp is carried out during the commissioning of the system. During the installation of polypropylene, polyethylene or metal-plastic elements, gaps may form in the attachment points. In the future, any of these places can cause leakage during operation.

Using the pump, areas with a high risk of leakage can be quickly detected. Inside the system, pressure is created with a level much higher than the maximum working pressure. If the pipes are able to withstand it for several hours, this suggests that they will work for a long time in normal mode. The pump helps to evaluate the quality of the repair work. All elements of the pipeline, for example, risers, must be checked before starting, forcing them to work under high pressure.Before work, it is necessary to prepare the system, if it is autonomous, you will need to turn off the heat generator.

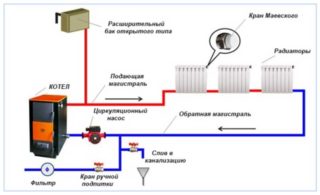

In a non-autonomous system, the area to be inspected is blocked by cranes. It is important to ensure that the coolant is drained. After the circuit, the system is filled with water heated to a temperature of not more than 45 degrees, during the filling process, the air will begin to gradually leave. At the next stage, the compressor is connected for crimping, the pressure is brought to the working mark and the site is inspected for damage. Then the pressure is gradually increased and left at the right level for 10-15 minutes. The pressure level is regulated by a manometer. All places are inspected for leaks, radiators, fittings and pipe walls are checked, all cranes and valves are in good condition.

Preventive pressure testing of systems allows you to prevent possible leaks and accidents, to identify and repair damage in the early stages. A hydraulic manual or electric press for crimping pipelines additionally helps to determine the degree of wear of pipes and the expected timing of their replacement.

All defects are recorded, according to the results of the audit, an act is prepared. This document fixes the time period during which the system was tested, and indicates its level. It is also necessary to indicate the type of check, which may be primary, regular or preventive or emergency in the event of a sudden leak or other malfunction.