Sprayed thermal insulation is a substance that is superior in many technical characteristics to rolled, plate and putty analogues. This technology is deservedly considered the most advanced and promising. Combining many positive characteristics, the material has almost no flaws. A few disadvantages are easily eliminated by using some simple tricks. Manufacturers offer consumers sprayable heaters that vary in technical characteristics, composition, applications and equipment used for application.

What is a spray heater

The sprayed insulation is a binary type substance consisting of two liquid components. After bringing to the required consistency, the products are mixed and applied through a spray gun to the treated surfaces. Under the influence of oxygen, an exothermic reaction is launched from the air, accompanied by the formation of a large amount of foam. Hardening lasts several minutes, as a result a porous dense mass with a cellular structure is formed. The top layer is dense like a vegetable peel of white color. Over time, under the influence of ultraviolet light, it darkens, acquiring a yellow or brown tint.

Depending on the ingredients used, these types of polyurethane foam insulation are distinguished:

- Elastic. After crystallization, the open-cell insulator resembles a penlex. It differs in good vapor permeability, flexibility and elasticity. Designed for finishing buildings made of wood and other breathable materials.

- Hard. The substance is characterized by high density and low weight. It is used in everyday life for sealing cracks and warming structures made of concrete and steel.

- Integral. It is characterized by high density, strength and resistance to mechanical stress. It is mainly used in industry at engineering facilities.

The sprayed polyurethane insulation is popular in private and commercial construction due to its wide scope.

Where is the material used

Foam insulation of a new generation is used for external and internal application. Depending on the characteristics of the objects, materials with open and closed cells are used.

Spraying is carried out on such structures:

- Roofs of residential, utility, administrative buildings and engineering structures. Since the main heat losses occur through the roof, a layer of 10-15 cm thick is applied for their high-quality insulation. When working in attic rooms, additional finishing is not required. The sprayed Polynor insulation after solidification forms a strong outer crust. At the same time, there are no smells and secretions.

- Technological capacities. The use of polyurethane foam in cylinders for the insulation of various tanks helps to maintain the set temperature in them with minimal energy consumption. Household and industrial boilers are filled with polyurethane, foam is applied to the walls of pools, storages and other containers for storing and transporting various liquids that require stable conditions. In addition to reservoirs, foam is used to isolate pipes brought to them having d 20 cm or more.

- Walls. For harsh climates, Polinor insulation is an excellent solution to the problem of combating freezing of load-bearing structures. The material is in no way inferior in its characteristics to the foam insulation roll insulation, surpassing it in application speed and durability.The layer thickness varies between 5-10 cm, depending on the type of structure and the climate. Spraying is carried out inside the lattice frame, which is then sheathed with decorative cladding.

- The floors. The thick layer of PP is an excellent protection against cold and damp, coming from the ground or unheated basements. The material is applied to a concrete slab or rough floor in a wooden house. Pre-made crate, which is the basis for laying a finishing or intermediate coating. Ventilation of premises is achieved by arrangement of products. Recommended application layer is 7-10 cm.

- Attic The insulation of these residential buildings with polyurethane foam allows you to create comfortable living conditions at any time of the year. To create a reliable barrier against cold and heat, spray at least 15 cm of foam. After that, the inner surfaces of the attic are sheathed with drywall, plywood or a massive board.

Depending on the processing area, industrial equipment or single sprayers are selected.

Material benefits

Specialists in the field of construction prefer polyurethane foam in favor of analogs such as insulation shells, matte and solid insulators.

Pros of PPU:

- Ecological cleanliness. The foam does not contain substances harmful to humans and the environment. It can be used safely in residential and outdoor areas.

- Low coefficient of thermal conductivity. This figure is significantly lower than that of such popular insulators as basalt cotton wool and polystyrene.

- Lack of hygroscopicity. The coating does not absorb water, always remains light and dry.

- Excellent soundproofing. The material cuts off street noises and prevents loud noises from leaving the room.

- Biological inertness. Fungus and mold do not start in the foam; rodents, birds and insects avoid it.

- Resistance to active chemicals. The substance does not respond to exposure to motor fuel, acids, alkalis, parasite control agents, oil and acrylic paints.

- Long term of operation. Depending on the type and brand of the manufacturer, the service life is 30-50 years. No foam is required for this foam.

- Corrosion protection. Due to the tight fit to the surface, the PUF prevents the formation of condensation on it and moisture from the outside.

- Lack of joints and voids. Foam fills all the smallest cracks and holes, covers the surface with a monolithic layer in which there are no cold bridges.

- Fire safety. The material is not combustible, but when in contact with an open flame emits toxic fumes.

- Resistance to extremely low and high temperatures. The range of application is from - 80 ºС to + 120 ºС.

- The ability to process surfaces of any complexity and inaccessible elements of engineering structures.

- Maintainability. If part of the coating is damaged, it is enough to fill the recess with the same material purchased in the hardware store.

- Profitability. There is no need to install vapor barrier and windproof films, pre-treatment of frames and bases.

- Speed of application. Finishing speed is an order of magnitude higher than that of rolled and tiled analogues.

An important factor in favor of choosing PPU is its cost. On average, the polynor consumption per m2 is 55-65 rubles, depending on the selected manufacturer and the equipment used.

Varieties of sprayed heaters

The technology of warming objects with foam is naturally considered the most effective and promising. To achieve a quality result, you should familiarize yourself with the varieties of sprayed insulation and the procedure for their use. Means are divided ready for application and requiring preliminary preparation.

The sprayed thermal insulation in cylinders is freely available and is familiar to almost every home master. Aerosol cans sold in hardware stores have a capacity of 500-1500 ml. Inside is a liquid composition saturated with compressed air. Different models have their own bell or are designed for installation in a special gun. Spraying is carried out after shaking and turning the product upside down by pulling the trigger. One 1000 ml can is enough to form 20 liters of foam or cover 1 m2 of the surface with a layer of 2 cm thick. This type of insulation can be used to treat small surfaces up to 10 m2. But even in this situation, 25 cartridges will be required to create a 5 cm layer, which is the minimum allowable for the arrangement of buildings.

Industrial mixtures are made from several liquid components immediately before use. Raw materials consist of their basic composition and hardener. Sealed containers, a high pressure hose, a spray gun and a pneumatic installation are used for carrying out. The optimum temperature for the work is + 20-25 ° C. Deviations lead to the fact that the solution foams too weakly or strongly. Both options lead to deviations of operational characteristics from the norm. If weather conditions do not meet the requirements, the solution is heated or cooled.

The material is supplied from the bottom up, the thickness of each layer should be within 3-4 cm. To achieve the desired effect, it is necessary to process the surface 2-3 times after the complete hardening of the previous layers.

Use industrial equipment to protect the skin, organs of vision and breathing. The substance has a high degree of adhesion; it is extremely difficult to remove from the body, clothing and surfaces. Therefore, places that do not need insulation should be reliably closed.

Most popular brands

The construction market is filled with foam insulation of domestic and foreign production. The most positive reviews were collected by the following brands:

The construction market is filled with foam insulation of domestic and foreign production. The most positive reviews were collected by the following brands:

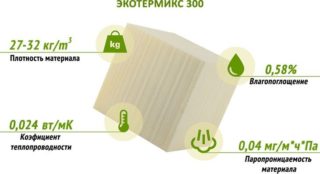

- Ecothermix;

- Titanium;

- TechnoNIKOL;

- Technology;

- Teplis;

- Polinor

- Phorum;

- Penosil;

- Penoplex Fastfix;

- Home master;

- Sipur;

- Tri color.

When choosing a material, you need to carefully study the instructions for use, lastly focusing on the price of products.